Scaffold capable of conveying materials

A technology of scaffolding and materials, which is applied in the field of scaffolding, can solve problems such as height adjustment, hidden dangers, and low safety factor, and achieve the effects of improving anti-tilting effect, enhancing stability, and improving safety factor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

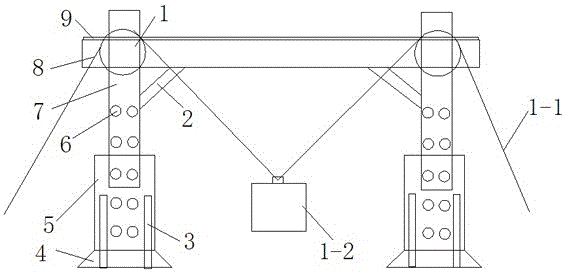

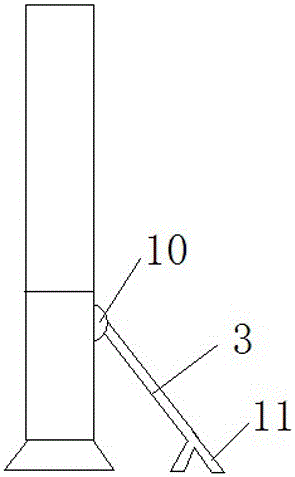

Embodiment 1

[0021] Embodiment one: if figure 1 Shown, the present invention comprises scaffold cross bar 8 and the scaffold vertical bar that is arranged on the scaffold cross bar two ends, and scaffold vertical bar is connected with the scaffold support bar 7 that is connected with scaffold cross bar 8 and support post 5, and described scaffold support bar 7 is connected with The support column 5 is correspondingly provided with several rows of height adjustment holes 6 which are not less than two in each row and is fixed through the height adjustment holes 6 through the fixing piece. fixed, the support base 4 is provided at the bottom of the support column 5, the anti-tilt support rod 3 is provided on the outside of the support column 5, the pulley 1 is provided on the outside of the locking member, and a rope 1- 1 connected, the rope 1-1 is provided with a material box 1-2. The present invention applies downward pressure on both ends of the rope 1-1 by setting the pulley 1, the rope 1...

Embodiment 2

[0023]Embodiment two: the present invention comprises scaffold cross bar 8 and the scaffold vertical bar that is arranged on the two ends of scaffold cross bar, and scaffold vertical bar is connected by the scaffold support rod 7 that is connected with scaffold cross bar 8 and support column 5, and described scaffold support rod 7 Corresponding to the support column 5, there are several rows of height adjustment holes 6 that are not less than two in each row and are fixed through the height adjustment holes 6 through the fixing piece. The buckle is fixed, the bottom of the support column 5 is provided with a support base 4, the outside of the support column 5 is provided with an anti-tilt support rod 3, the outside of the lock is provided with a pulley 1, and a rope 1 is passed between the two pulleys 1 -1 connection, the rope 1-1 is provided with a material box 1-2. The present invention applies downward pressure on both ends of the rope 1-1 by setting the pulley 1, the rope ...

Embodiment 3

[0026] Embodiment three: the present invention comprises scaffold cross bar 8 and the scaffold vertical bar that is arranged on the two ends of scaffold cross bar, and scaffold vertical bar is connected by the scaffold support rod 7 that is connected with scaffold cross bar 8 and support column 5, and described scaffold support rod 7 Corresponding to the support column 5, there are no less than five rows of height adjustment holes 6 with no less than three height adjustment holes in each row and are fixed through the height adjustment holes 6 through the fixing parts. The space is fixed by a locking piece, the bottom of the supporting column 5 is provided with a supporting base 4, the outer side of the supporting column 5 is provided with an anti-tilt support rod 3, the outer side of the locking piece is provided with a pulley 1, between the two pulleys 1 They are connected by a rope 1-1, and a material box 1-2 is arranged on the rope 1-1. The present invention applies downwar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com