Method applicable to repeatedly transforming stratum nearby shaft of low-pressure gas field old well to complete permanent blocking

A technology of repeated reconstruction and close to the wellbore, applied in wellbore/well components, chemical instruments and methods, earthwork drilling and production, etc., can solve the problem of large loss of killing fluid and fracturing fluid, long fluid drainage period, and lack of formation energy and other problems, to achieve good fluidity and penetration, improve the efficiency of seam making, and the effect of small particle size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

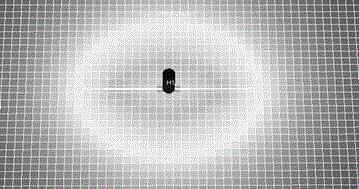

Image

Examples

Embodiment 1

[0033] This example provides a method suitable for permanent plugging of the formation near the wellbore for repeated reconstruction of old wells in low-pressure gas fields. The pores and cracks in the surrounding low pressure deficit area are permanently blocked.

[0034] Technical principle: With the help of micron-scale resin, it is pumped into the reservoir around the wellbore before repeated fracturing. Due to the small particle size of the ultra-fine plugging agent, it has good fluidity and penetration, and can penetrate into the pores of the reservoir. Pores and fractures in the low-pressure deficit area around old wells are permanently sealed to slow down the leakage of fracturing fluid into the formation and improve the fracture-making efficiency of fracturing fluid.

Embodiment 2

[0036] On the basis of Example 1, a method suitable for repeated reconstruction of old wells in low-pressure gas fields and permanent plugging of near-wellbore formations includes the following steps:

[0037] Step 1) Determine the mixing ratio and injection volume of micron-sized resin and cement according to the recovery degree of the gas well and the thickness of the gas layer;

[0038] Step 2) The micron resin is mixed with cement and then pumped into the formation near the wellbore;

[0039] Step 3) close the well and wait for Ning;

[0040] Step 4) Nitrogen pressure test 30MPa, pressure drop for 30 minutes, if the pressure drop is less than 0.5MPa in 30 minutes, it indicates that the formation near the wellbore is successfully sealed, and proceed to step 5); if the formation near the wellbore is unsuccessful, repeat step 2 ) and step 3);

[0041] Step 5) After the plugging is qualified, re-perforate the target interval;

[0042] Step 6) Repeat the fracturing stimulati...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com