Method for preparing magnesiumhalide nano material

A technology of nanometer material and magnesium halide, which is applied in the field of preparation of magnesium halide nanometer microspheres, and achieves the effect of uniform distribution and small particle size.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

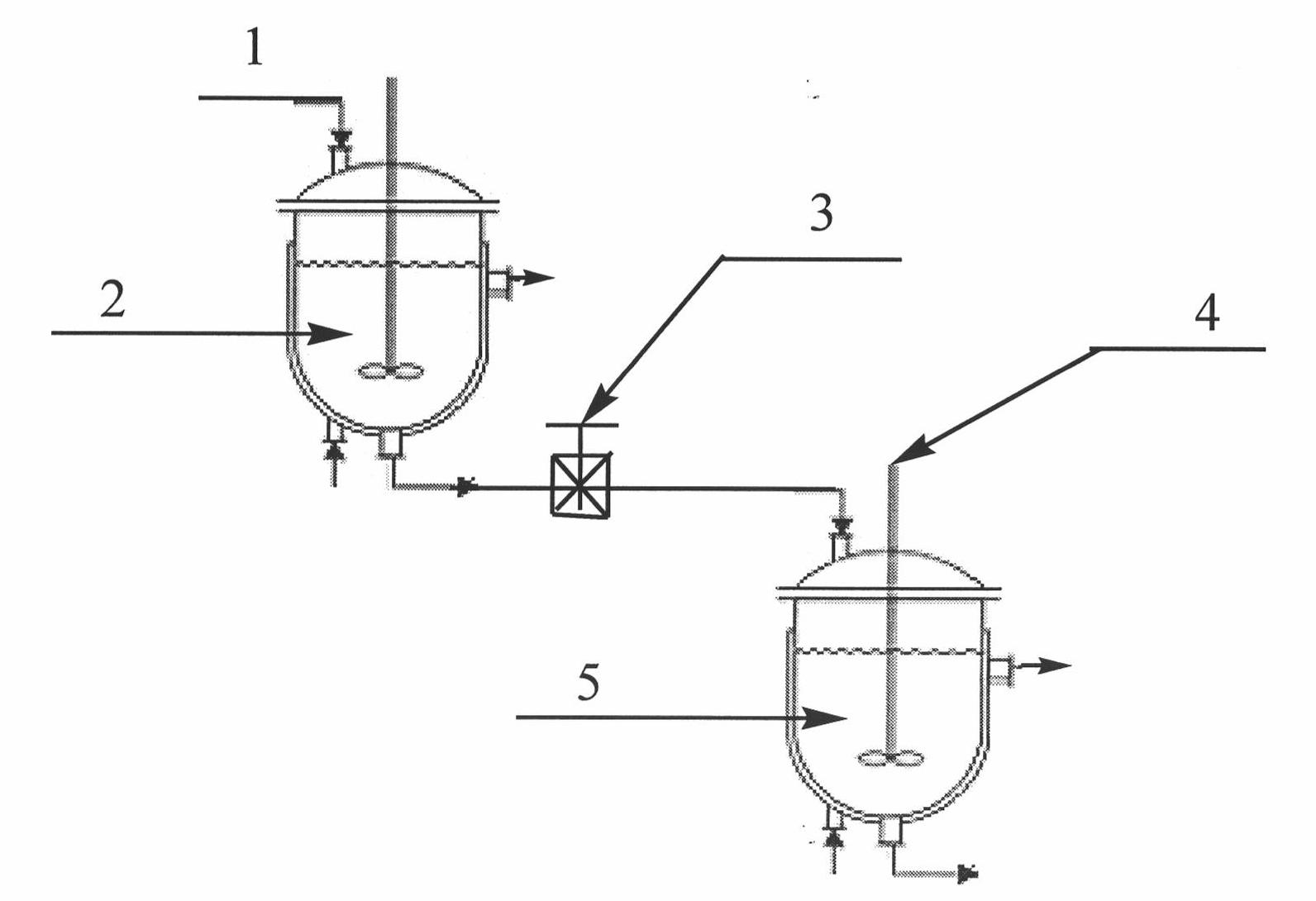

Method used

Image

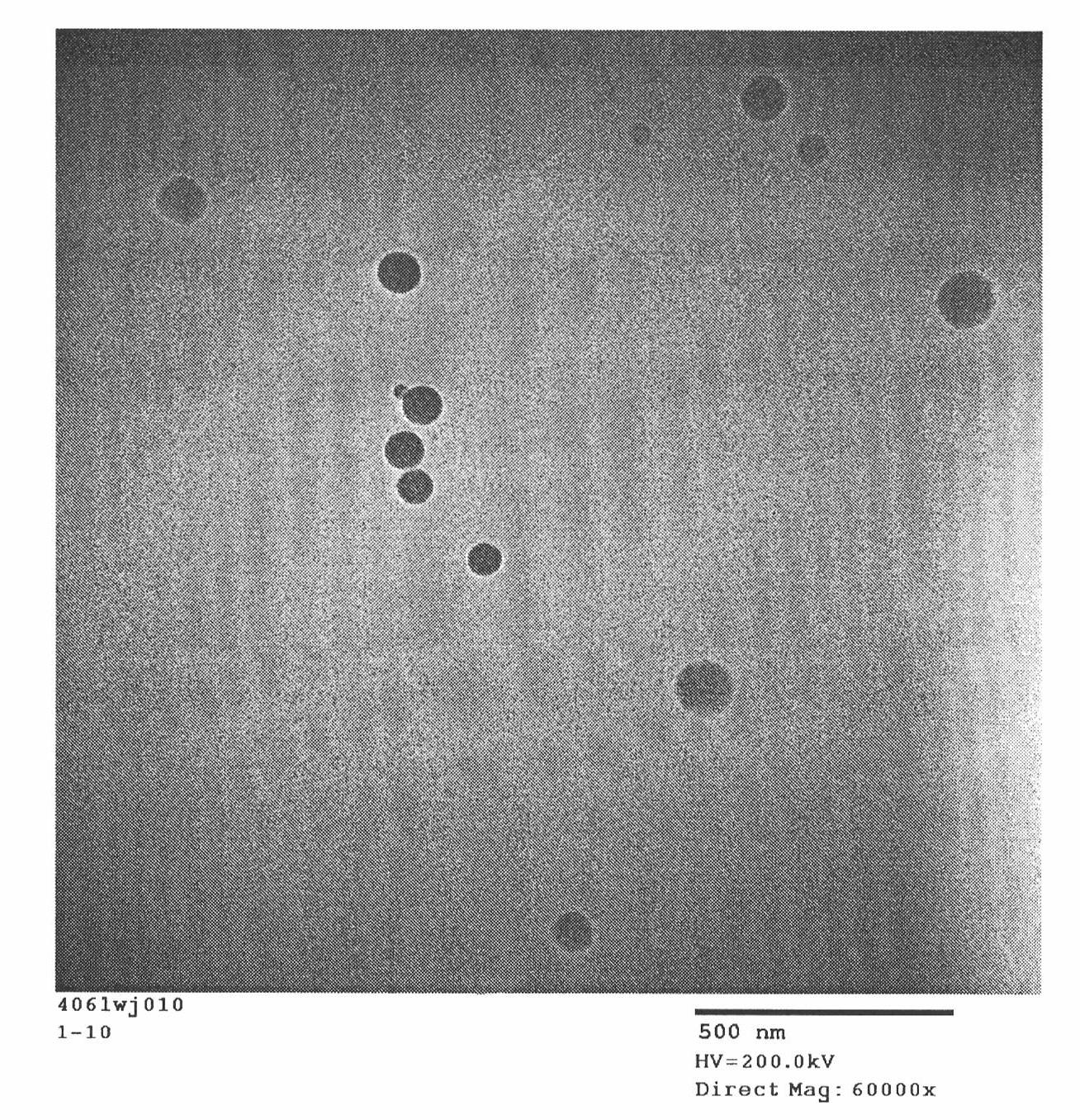

Examples

Embodiment 1

[0033] In a reactor fully replaced with nitrogen, add 1 g of anhydrous MgCl 2 , 10ml of ethanol, stirred, controlled temperature is about 120 ℃ and reacted for 3 hours, transferred to the mixed emulsion (coolant) of 0.3g vacuum ester and 50ml hexane at 30 ℃ while it was hot (120 ℃), the stirring speed of the coolant was 300 rpm, MgCl 2 The transfer rate of the ethanol solution was 0.5% / min of the total amount. After stirring for 20 min, stand and filter, wash with toluene 3 times and n-hexane 3 times (40 ml each time), and vacuum-dry to obtain 2.5 grams of spherical nano-magnesium chloride alcoholate particles.

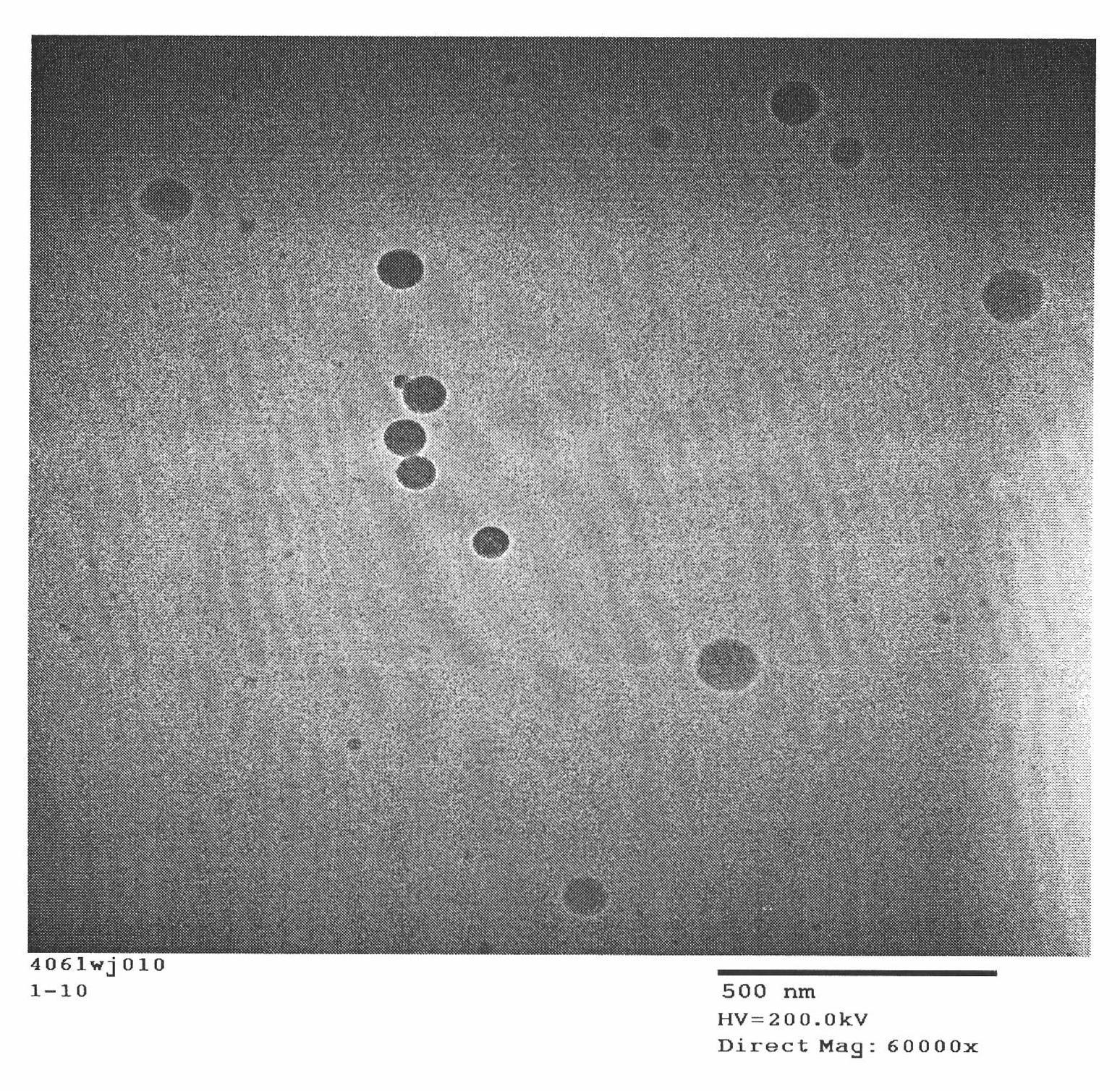

Embodiment 2

[0035] In a reactor fully replaced with nitrogen, add 1 g of anhydrous MgCl 2 , 20ml of ethanol, stir, control the temperature at about 120°C for 3 hours, transfer to the mixed emulsion (cooling liquid) of 0.2g silicon ester and 50ml pentane at 30°C while it is hot (120°C), the stirring rate of the cooling liquid is 400 rpm, MgCl 2 The transfer rate of the ethanol solution was 0.1% / min of the total amount. After stirring for 20 min, stand and filter, wash with toluene 3 times and n-hexane 3 times (40 ml each time), and vacuum-dry to obtain 2.1 g of spherical nano-magnesium chloride alcoholate particles.

Embodiment 3

[0037] In a reactor fully replaced with nitrogen, add 1 g of anhydrous MgCl 2 , 30ml of absolute ethanol, stir, control the temperature at about 60°C for 3 hours, transfer to the mixed emulsion (coolant) of 3.0g white oil and 30ml heptane at -10°C while it is hot (60°C), the cooling liquid Stirring rate is 600 rpm, MgCl 2 The transfer rate of the ethanol solution was 5% / min of the total amount. After stirring for 5 hours, stand and filter, wash with n-hexane 3 times (40 ml each time), and vacuum-dry to obtain 0.9 g of spherical nano-magnesium chloride alcoholate particles.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com