Method for preparing loose low-oil absorption magnesium-calcium powder

A technology of oil absorption and magnesium calcium, applied in the direction of magnesium carbonate, calcium carbonate/strontium/barium, etc., can solve the problems of affecting application, poor dispersion and compatibility, etc., achieve high social and economic benefits, and invest in less equipment , The effect of short process flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

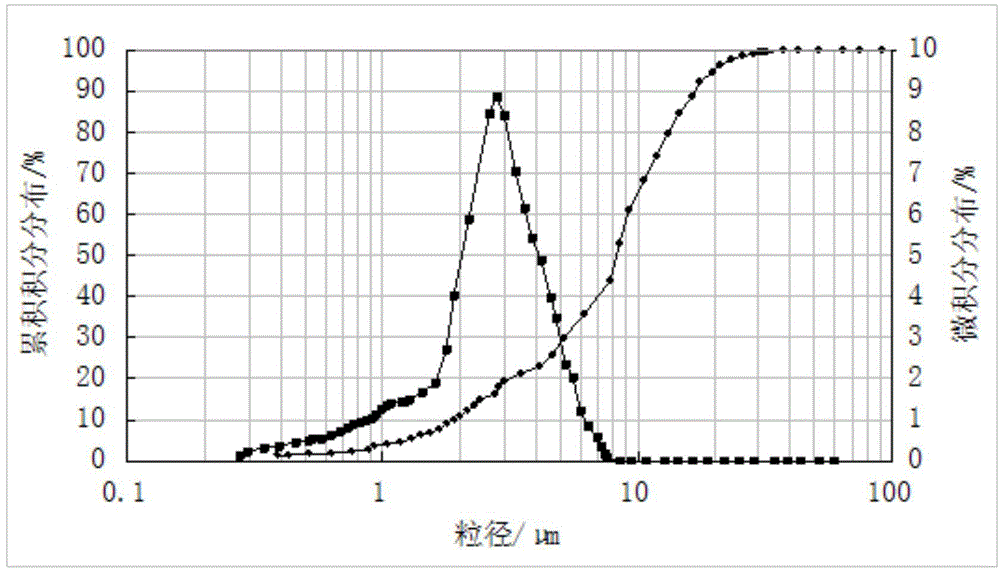

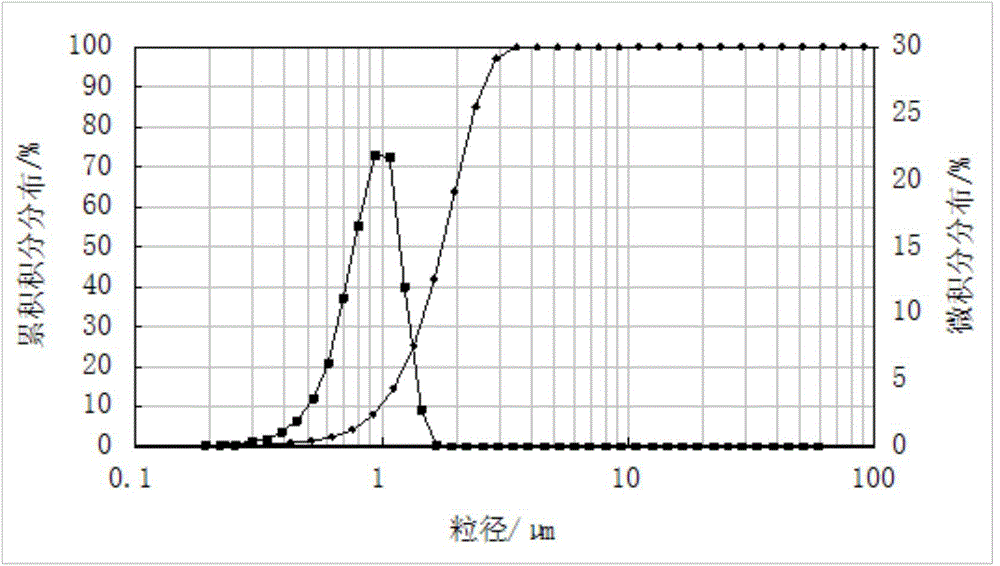

[0020] Take 490kg of magnesium-calcium wet slag with a moisture content of 59.4% after detoxification and add it to the mixing tank, add 1500L of water, and pump it into 5m after fully stirring to form a uniform suspension slurry. 3 Reactor, add stearic acid 5kg, sodium stearate 4kg, glycerin 1kg, add stearic acid 5kg, sodium stearate 5kg again when heating up to 85 ℃, cool after reacting for 2 hours. The cooled slurry is then dehydrated and dried to obtain the final product loose magnesium calcium powder with low oil absorption. Take a part of the original magnesium-calcium powder to measure its particle size distribution and oil absorption. A part of the processed loose low oil absorption magnesium calcium powder sample was taken to measure its activation rate, particle size distribution and oil absorption. The activation rate of the loose type low oil absorption magnesium calcium powder is determined to be 99.5%. Particle size D before treatment 50 8.94μm, the particle s...

Embodiment 2

[0022] Take 480kg of magnesium-calcium wet slag with a moisture content of 52% after detoxification and add it to the mixing tank, add 1360L of water, and pump it into 5m after fully stirring to form a uniform suspension slurry. 3 Reactor, add stearic acid 5.5kg, sodium stearate 1.5kg, glycerol 1kg, add stearic acid 6.5kg, sodium stearate 2.0kg when heating up to 80 ℃, cool after reacting for 1.5 hours. The cooled slurry is then dehydrated and dried to obtain the final product loose magnesium calcium powder with low oil absorption. Take a part of the original magnesium-calcium powder to measure its particle size distribution and oil absorption. A part of loose low oil absorption magnesium calcium powder sample was taken to measure its activation rate, particle size distribution and oil absorption. The activation rate of the loose type low oil absorption magnesium calcium powder is determined to be 99.8%. Particle size D before treatment 50 9.67μm, the particle size D after ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com