Compression spring type six-degree-of-freedom quasi-zero stiffness vibration isolator and design method thereof

A compression spring, quasi-zero stiffness technology, applied in spring/shock absorber, shock absorber, low internal friction spring, etc., can solve the problem that there are few researches on quasi-zero stiffness vibration isolators with six degrees of freedom, and achieve low price , good reliability, and simple structural system

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further described in detail below with reference to the drawings and specific embodiments.

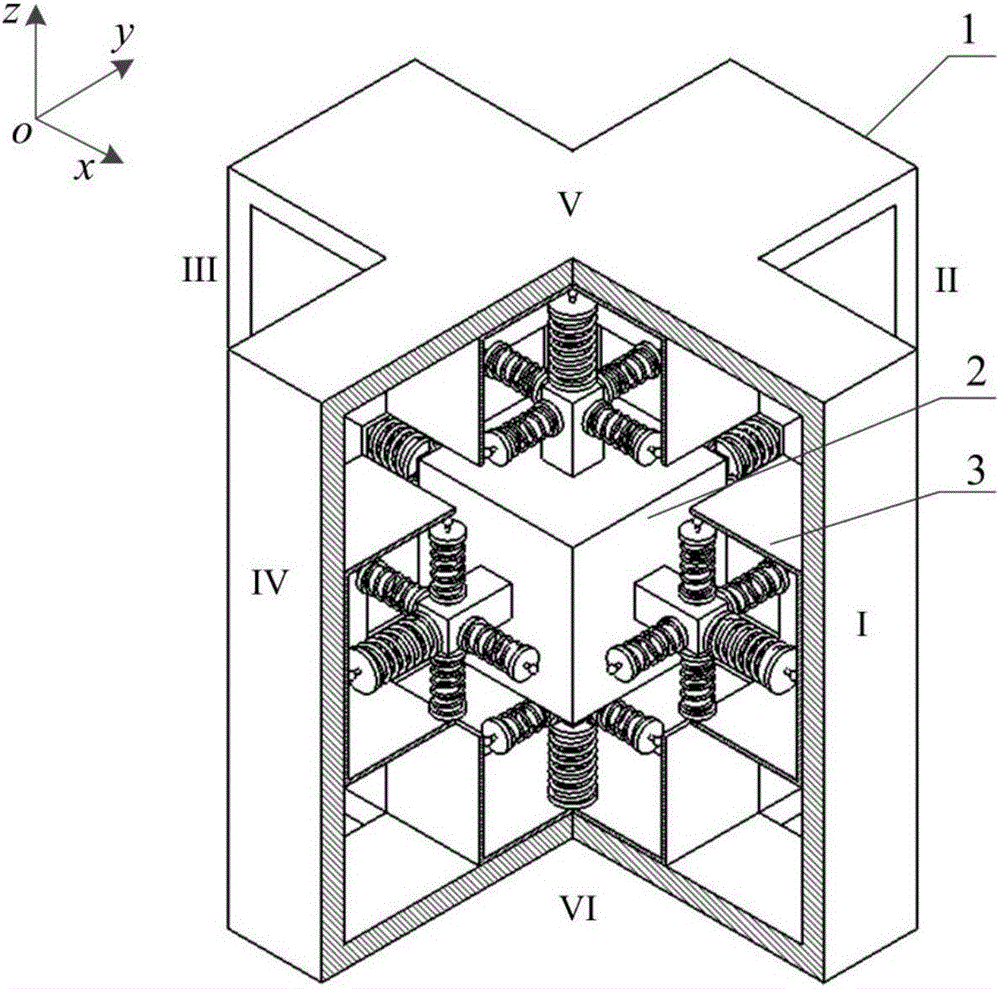

[0030] Such as figure 1 As shown, a compression spring type six-degree-of-freedom quasi-zero stiffness vibration isolator of the present invention includes an outer frame 1, a vibration-isolated box 2, and 6 isolators distributed on six surfaces of the vibration-isolated box 2. Vibration module 3. The outer frame 1 is fixed to the foundation. When the foundation vibrates, the frame 1 will vibrate. Objects that need vibration isolation are installed in the vibration isolation box 2. The bottom of the vibration isolation module 3 is fixed through the frame 3.1 and the outer frame 1, and the other end is connected to the vibration isolation box 2 through a connecting piece 3.2.

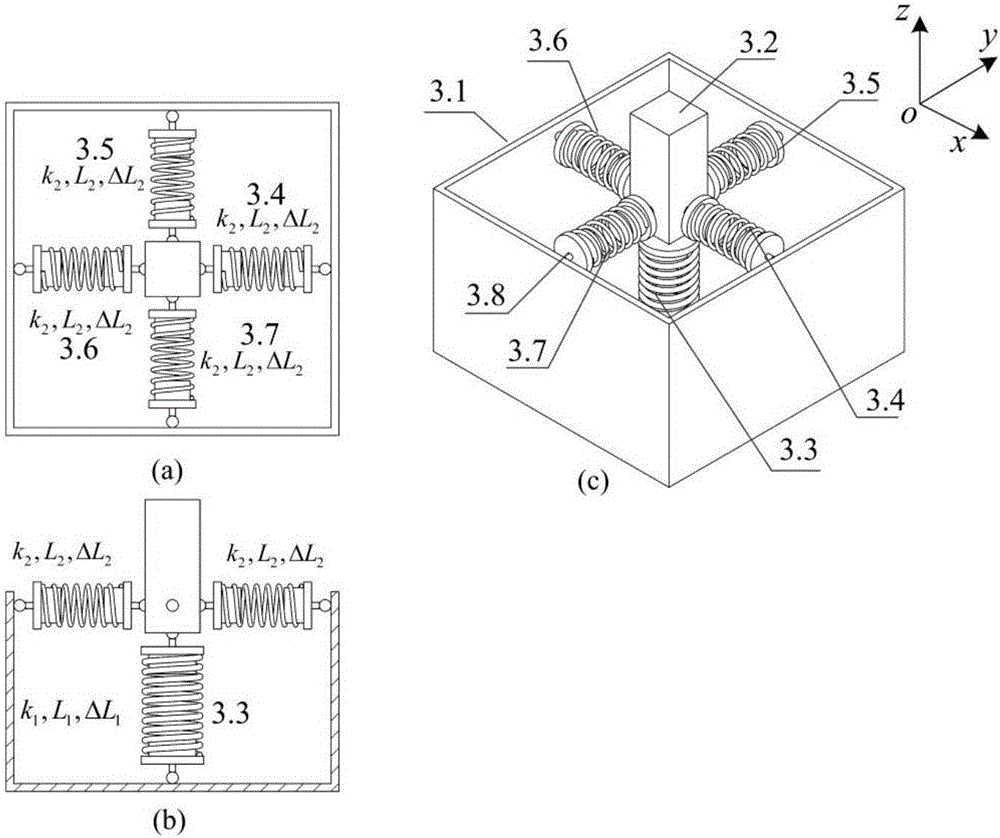

[0031] Such as figure 2 As shown, the vibration isolation module 3 consists of a frame 3.1, a connector 3.2, a vertical compression spring 3.3, and four lateral compression spr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com