Chemical feeding device based on improving mixing uniformity of chemical

A technology of mixing uniformity and dosing device, which is applied in mixers, fluid mixers, transportation and packaging, etc., and can solve the problems of adding mixing devices

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

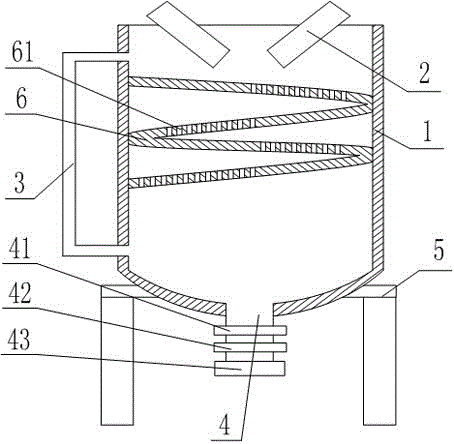

[0029] Such as figure 1 As shown, the dosing device based on improving the uniformity of medicament mixing includes a fixing frame 5, a tank body 1 is arranged on the fixing frame 5, and the top of the tank body 1 is provided with two inlets 2 and two inlets 2 The outlet ends are arranged oppositely, the bottom of the tank 1 is provided with a discharge pipe 4, and the discharge pipe 4 is provided with a valve 42. The tank 1 is provided with a spiral plate 6. The inflection point of the spiral plate 6 and the inner wall of the tank 1 In contact, the lower end of each layer of the spiral plate 6 is provided with a through hole 61.

Embodiment 2

[0031] Such as figure 1 As shown, this embodiment is based on embodiment 1. The side wall of the tank body 1 is provided with a bypass pipe 3, two ends of the bypass pipe 3 are respectively connected with the upper end and the lower end of the tank body 1, and the bypass pipe 3 Made of transparent materials; the discharge pipe 4 is provided with a metering pump 41; the outlet end of the discharge pipe 4 is provided with a joint 43; the inclination of each layer of the spiral plate 6 is 30°; The spiral plate 6 is provided with striped ribs.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com