Chemical polishing agent and metallographic structure display method of titanium alloy

A metallographic structure display and chemical polishing technology, which is applied to the polishing composition containing abrasives, testing metals, scientific instruments, etc., can solve the problems of easy white film, blackening, and affecting the quality of observation, so as to optimize the grinding process , solve the effects of deformation twins and clear metallographic structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0057] 1. Configure chemical polishing agent

[0058] by H 2 o 2 and SiO 2 Suspension composition, where, H 2 o 2 and SiO 2 The volume ratio of the suspension is 1:4.

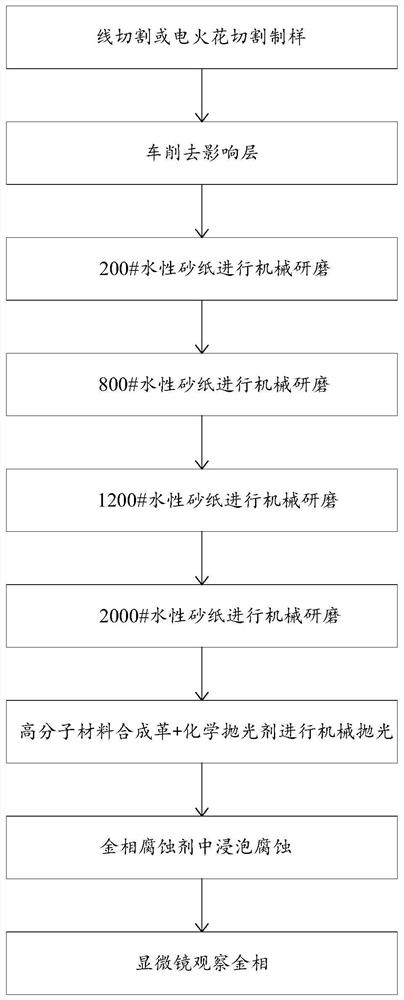

[0059] 2. Metallographic structure display method of titanium alloy

[0060] Titanium alloy material: Ti-6.5Al-3.5Mo-1.5Zr-0.3Si

[0061] Brand: TC11

[0062] Heat treatment process: heating to 1015°C, holding for 35 minutes, water quenching.

[0063] Metallographic etchant: 4mL HF, 15mL HNO 3 , 81mL distilled water

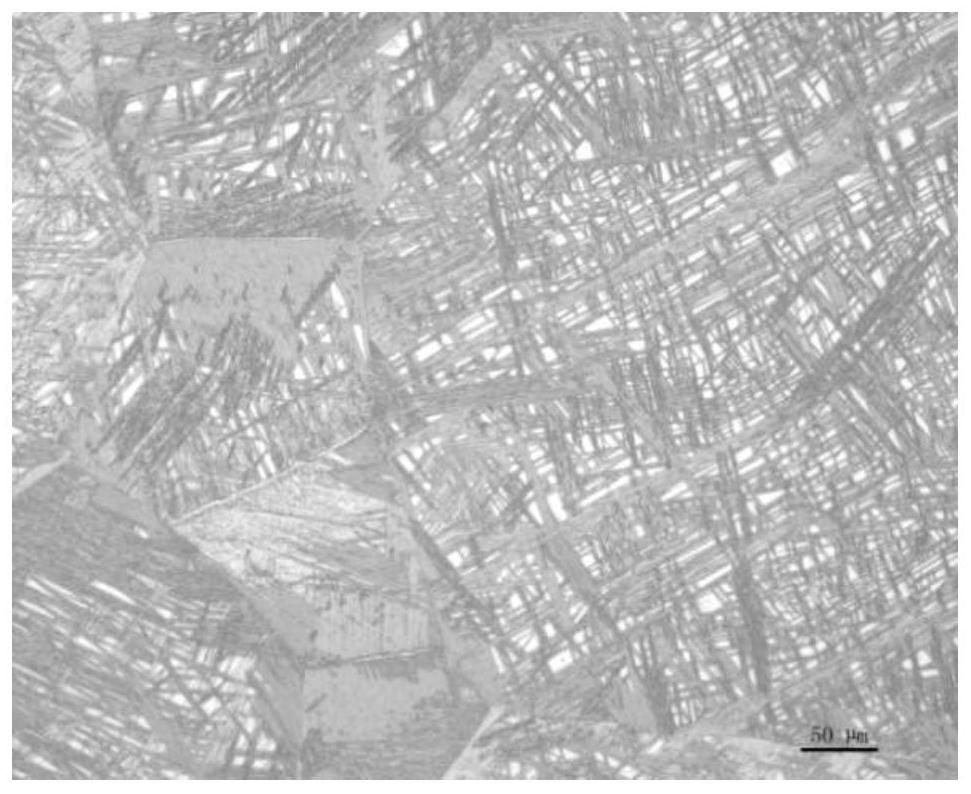

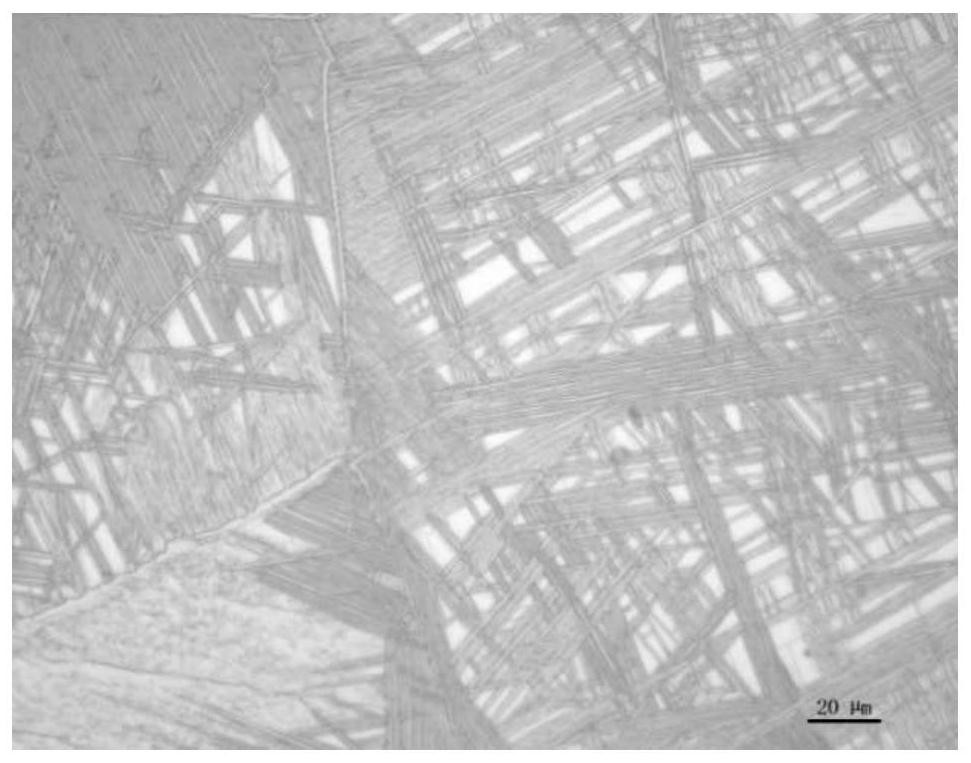

[0064] β phase between acicular martensite and needles

[0065] The result is as Figure 2-3 As shown, the microstructure is maintained at a temperature above the β transformation point and rapidly cooled, that is, acicular martensite + β phase. The length and broadband of martensite are very clear, which is very conducive to the analysis of the structure and properties of materials. .

Embodiment 2

[0067] 1. Configure chemical polishing agent

[0068] by H 2 o 2 and SiO 2 Suspension composition, where, H 2 o 2 and SiO 2 The volume ratio of the suspension is 1:4.

[0069] 2. Metallographic structure display method of titanium alloy

[0070] Titanium alloy material: Ti-6.5Al-1Mo-1V-2Zr

[0071] Grade: TA15

[0072] Heat treatment process: hot rolled state

[0073] Metallographic etchant: 4mL HF, 15mL HNO 3 , 81mL distilled water

[0074] nascent α+β transition tissue

[0075] The result is as Figure 4-5 As shown, the microstructure is composed of equiaxed α phase + β transformation structure, and the content of equiaxed α phase is about 35%, which is a typical two-state structure.

Embodiment 3

[0077] 1. Configure chemical polishing agent

[0078] by H 2 o 2 and SiO 2 Suspension composition, where, H 2 o 2 and SiO 2 The volume ratio of the suspension is 1:4.

[0079] 2. Metallographic structure display method of titanium alloy

[0080] Titanium alloy material: Ti-4Al-22V

[0081] Grade: TB13

[0082] Heat treatment process: solid solution (ST)

[0083] Metallographic etchant: 20mL HF, 15mL HNO 3 , 65mL distilled water

[0084] single equiaxed beta tissue

[0085] The result is as Figure 6-7 As shown, the microstructure is equiaxed metastable β grains, and the grain boundaries appear clearly, which makes the grain size evaluation more accurate. According to the GBT 6394-2017 metal average grain size determination method, the grain size is rated as 9.3.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com