Bottom flow shearing and thickening device and method for thickener

A thickener and machine bottom technology, applied in the thickener field, can solve the problems of low underflow concentration, inability to discharge, motor shutdown, etc., to achieve obvious economic benefits, reduce power consumption, and overcome the effects of low concentration efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The technical solution of the present invention will be described below in conjunction with the accompanying drawings and specific embodiments.

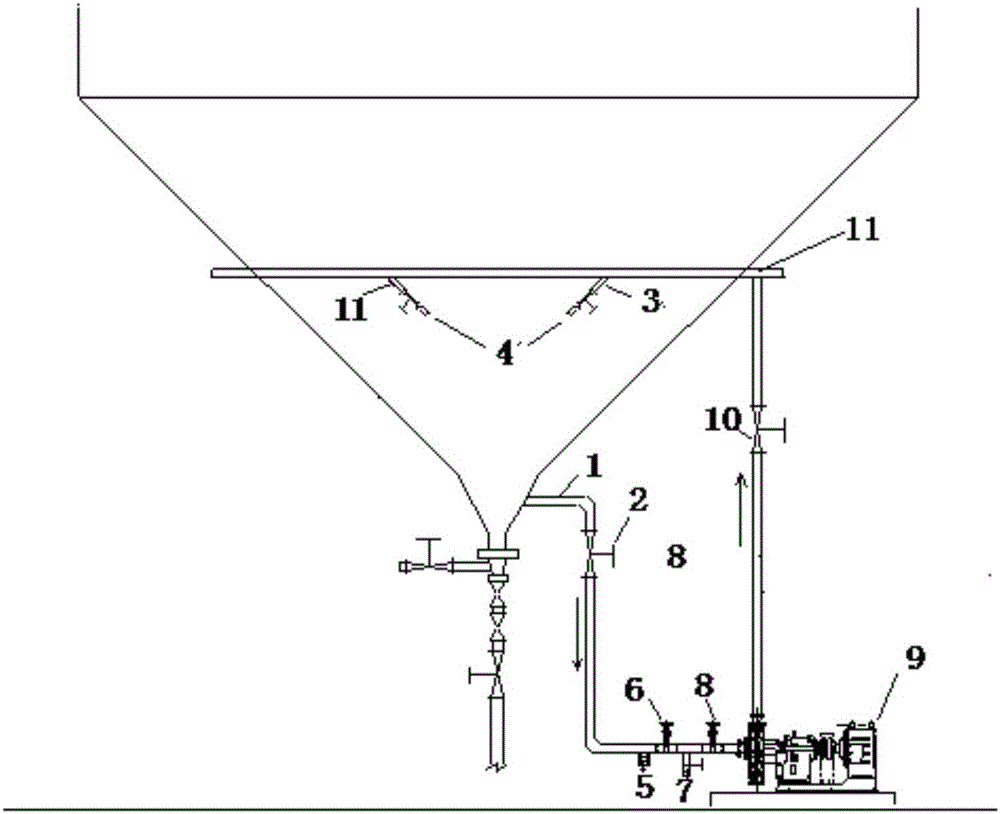

[0022] Such as figure 1 As shown, the underflow shear thickening device of the thickener of the present invention is connected to a suction pipe 1 on the bottom side of the thickener cone, and a circle of feeding pipes is arranged around the cone in the middle of the thickener cone 11. The feed pipe 11 surrounds the cone and connects with the suction pipe 1 through the circulation pump 9; the feed pipe 11 is provided with several symmetrical spraying branch pipes 3, and the spraying branch pipe 3 is equipped with a branch valve 4. The spraying branch pipe 3 enters perpendicular to the side wall of the cone; the main valve 2, the sewage valve 5, the sewage cleaning and recoil water valve 6 of the suction pipe, the sewage and recoil water inlet 7 and the water supply pipe are successively arranged on the suction pipe 1 Feed pip...

PUM

| Property | Measurement | Unit |

|---|---|---|

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com