Device for testing fatigue of connecting piece of one-arm three-dimensional measurement scribing instrument

A technology of three-dimensional measurement and test device, applied in the direction of measurement device, application of stable tension/pressure test material strength, instrument, etc., can solve the problems affecting the efficiency of bolt tensile test and the low connection efficiency of bolt and hydraulic testing machine, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

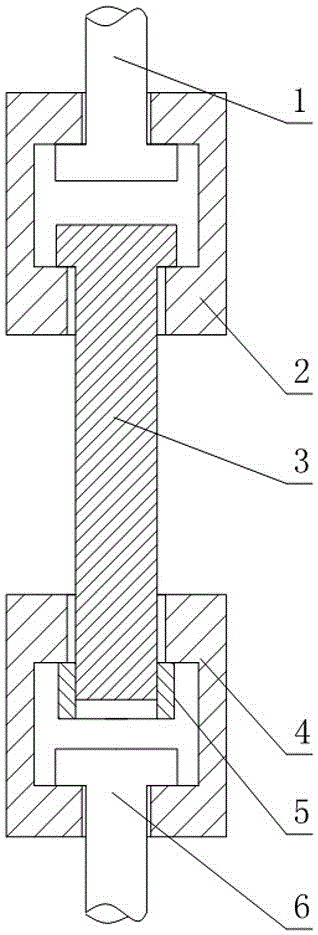

[0019] like figure 1 As shown, the test device for measuring the fatigue degree of the connecting part of the scribing instrument with a single arm three-dimensionally includes a first block 2 and a second block 4, and the first block 2 and the second block 4 are fixedly connected to the first block 2 and the second block 4 respectively. A pull rod 1 and a second pull rod 6, the first pull rod 1 is used for the fixed connection between the first block 2 and the hydraulic testing machine, and the second pull rod 6 is used for the fixed connection between the second block 4 and the hydraulic testing machine ;

[0020] The first block 2 and the second block 4 are all provided with a T-shaped slot, the width of the bottom end of the T-shaped slot is greater than the width of the opening end, and the depth direction of the T-shaped slot on the first block 2 is the same as that of the first block 2. The axial direction of a pull rod 1 is parallel, and the depth direction of the T-s...

Embodiment 2

[0024] like figure 1 As shown, this embodiment is further defined on the basis of Embodiment 1: in order to facilitate the uniformity of force on each point on the cross-section of the first pull rod 1, the first block 2, the screw or the nut 5, the first pull rod The axis of 1 is collinear with the centerline of the T-shaped slot on the first block 2.

[0025] In order to facilitate the uniformity of the stress on each point on the cross-section of the second pull rod 6, the second clamp block 4, the screw rod or the nut 5, the axis of the second pull rod 6 is in common with the center line of the T-shaped groove on the second clamp block 4. Wire.

[0026] In the absence of an auxiliary screw or nut 5, in order to make the clamp at least usable for the tension test of a threaded rod that is not provided with a 5 end of a nut at both ends, and a screw that is provided with a 5 end of a nut at one end, the first clamping block 2 A nut 5 is disposed in the T-shaped slot on the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com