Battery set equalization circuit based on soft-switch full bridge circuit and method

A full-bridge circuit and equalization circuit technology, applied in charge equalization circuits, circuit devices, battery circuit devices, etc., can solve the problems of small equalization current, long equalization time, slow equalization speed, etc., to meet the requirements of equalization current, energy The effect of high utilization and fast balancing speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

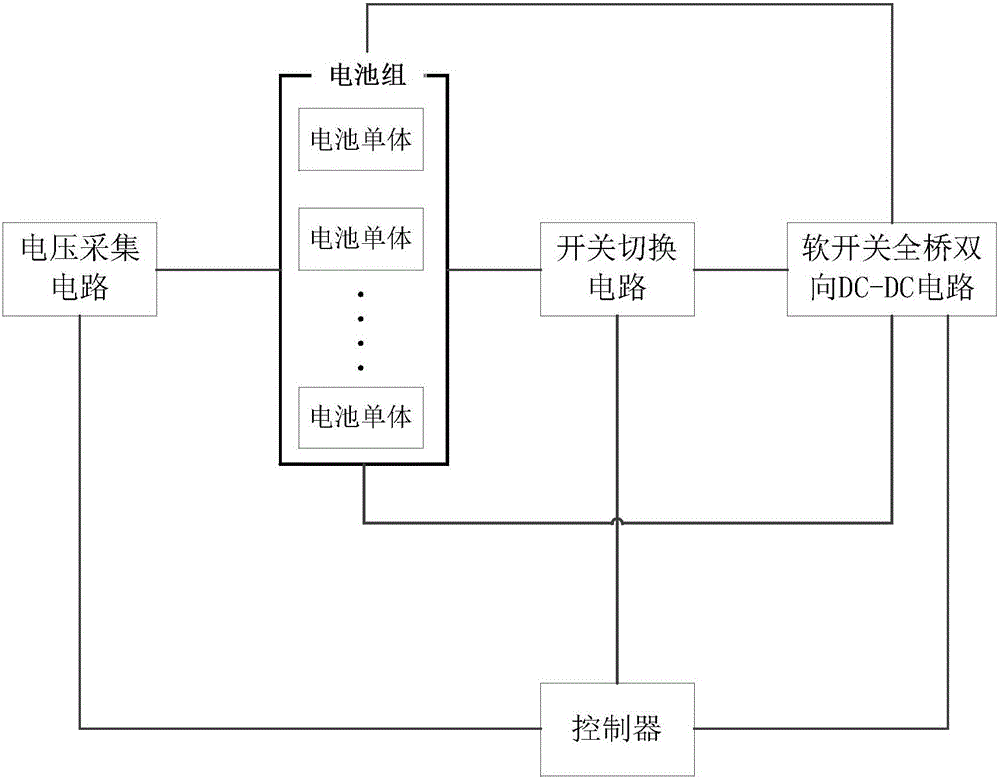

[0050] Such as Figure 1 to Figure 4 As shown, the battery pack balancing circuit based on the soft-switching full-bridge circuit includes a battery pack containing multiple battery cells, a voltage acquisition circuit, a switch switching circuit, a controller, and at least one soft-switching full-bridge bidirectional DC-DC circuit, The voltage acquisition circuit, the switch switching circuit and at least one soft-switch full-bridge bidirectional DC-DC circuit are all connected to the controller, the plurality of battery cells are all connected to the voltage acquisition circuit, and the soft-switch full-bridge bidirectional DC-DC circuit is connected to the controller. One end of the DC circuit is connected to the battery cell through a switch switching circuit, and the other end of the soft-switching full-bridge bidirectional DC-DC circuit is connected to the battery pack;

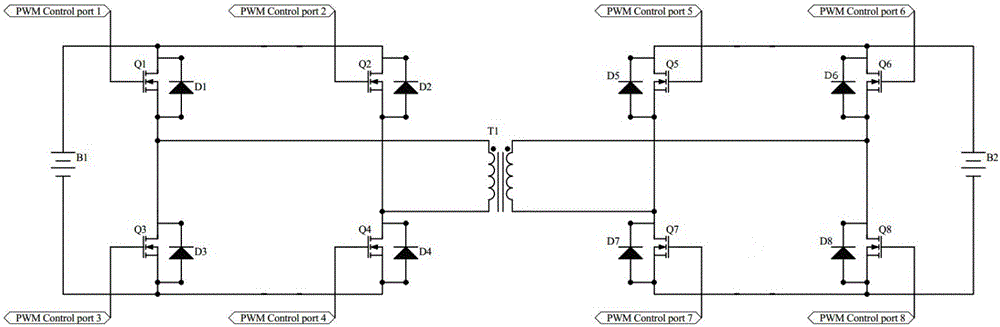

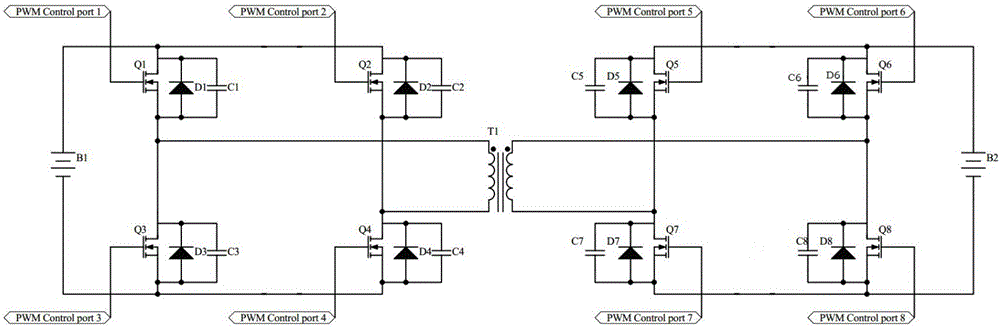

[0051] The soft-switching full-bridge bidirectional DC-DC circuit includes a transformer T1, a first...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com