A method for controlling the magnetic force of the electromagnetic pole of a magnetic suspension bearing based on a double-bridge structure

A magnetic bearing and magnetic control technology, applied in control/regulation systems, high-efficiency power electronic conversion, electrical components, etc., can solve problems such as high real-time requirements, bus voltage short-circuit faults, complex control circuits, etc., to solve the instantaneous bus voltage Short-circuit fault hidden danger, the effect of reducing the on-off loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

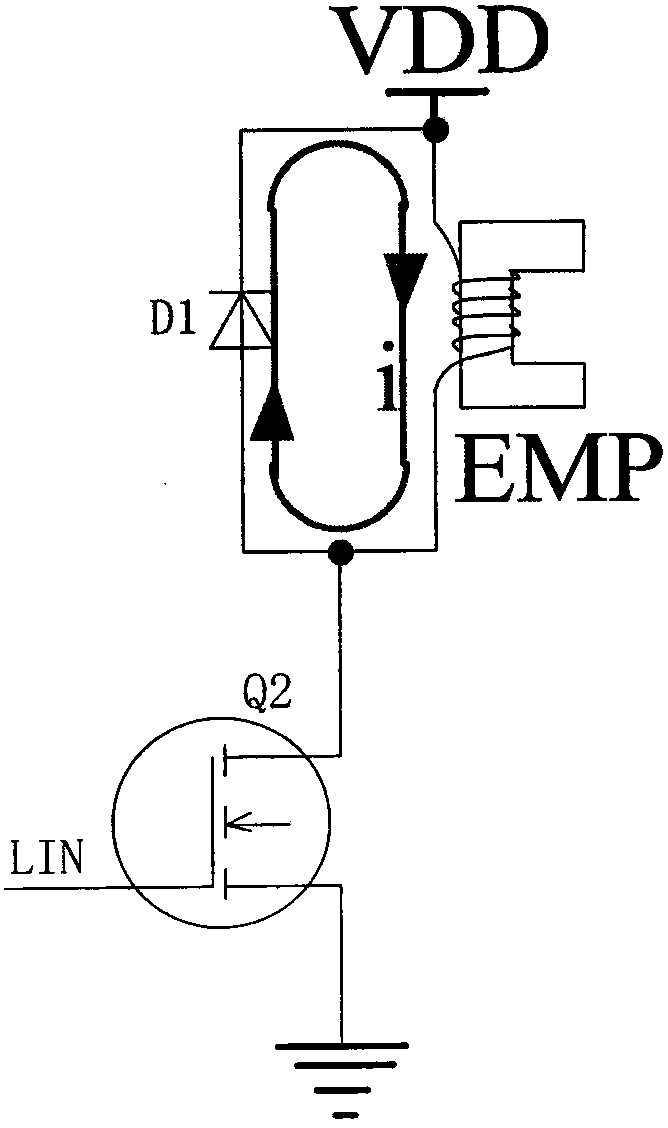

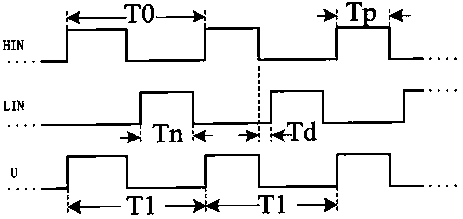

[0104] Embodiment 1: as Image 6 , a method for controlling the magnetic force of magnetic suspension bearing electromagnetic poles based on a double bridge structure, the power supply circuit of the magnetic suspension bearing electromagnetic poles adopts a main circuit with a double bridge structure, and the main circuit includes 2 power switching devices and 2 diodes: the first power a switching device (Q1), a second power switching device (Q2), a first diode (D1) and a second diode (D2);

[0105] The first power switching device and the second diode form a first bridge arm, and the second power switching device and the first diode form a second bridge arm;

[0106] In the first bridge arm, the first terminal of the first power switching device (Q1) is connected to the positive pole of the DC power supply (VDD); the second terminal of the first power switching device is the control terminal, which is connected to the control signal HIN, and the first power The third termin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com