Diaphragm and centrifugal rotating machine

A rotating machinery, centrifugal technology, applied in mechanical equipment, non-variable-capacity pumps, non-displacement pumps, etc., can solve problems such as reduced compression efficiency, unstable flow, and increased pressure loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

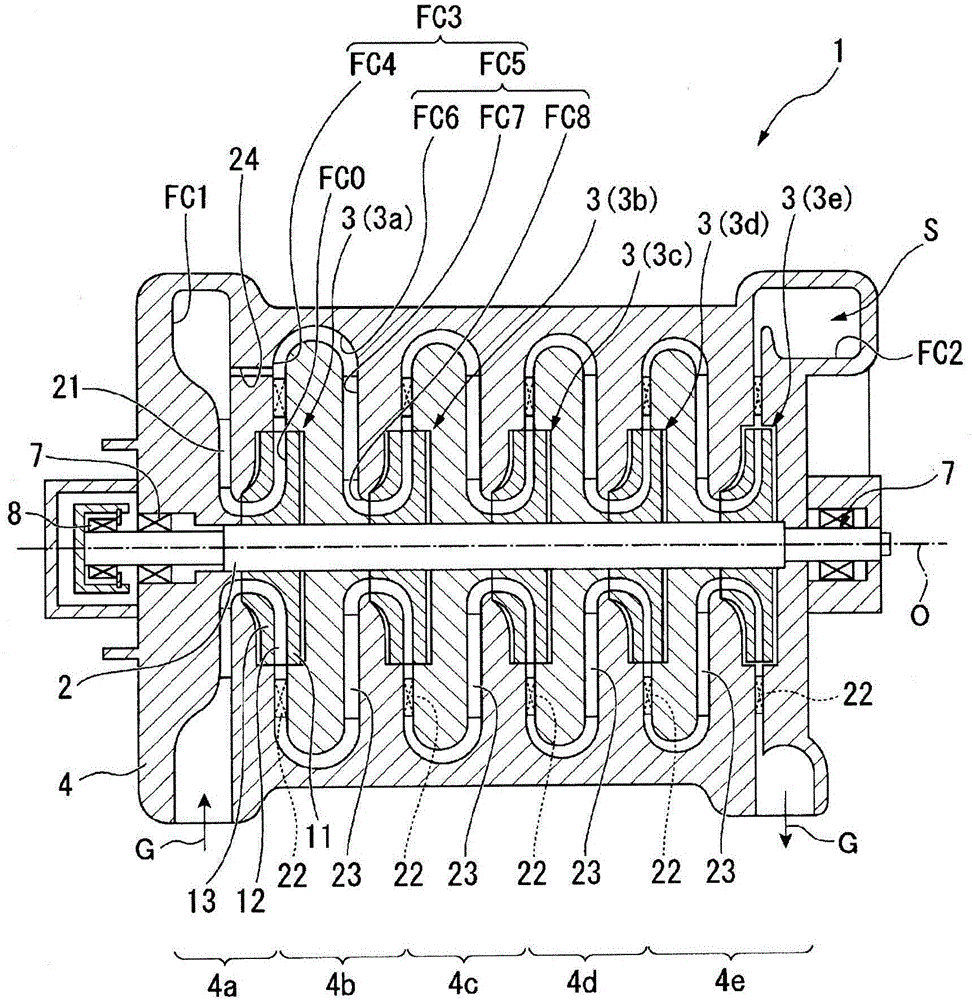

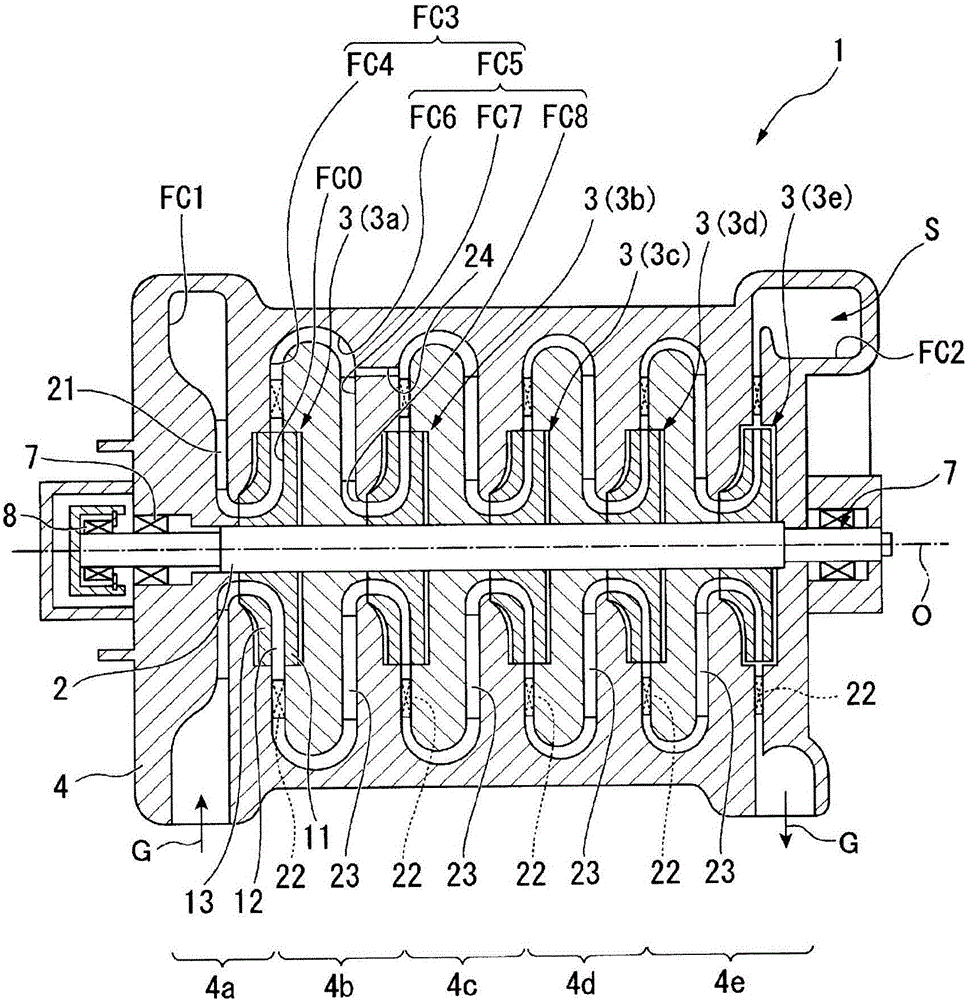

[0032] Hereinafter, an embodiment of the multistage centrifugal compressor 1 (centrifugal rotary machine) of the present invention will be described with reference to the drawings.

[0033] Such as figure 1 As shown, a multistage centrifugal compressor 1 includes a rotating shaft 2 rotating around an axis O, a plurality of impellers 3 attached to the rotating shaft 2, and a rotatably supported rotating shaft 2 formed to allow gas G such as air ( The shell 4 of the shell flow path FC through which fluid) flows.

[0034] The rotating shaft 2 has a cylindrical shape extending along the axis O and centered on the axis O. As shown in FIG. The rotary shaft 2 is relatively rotated around the axis O with respect to the casing 4 by a power source such as a motor (not shown).

[0035] The plurality of impellers 3 are arranged at intervals in the axis O direction where the axis O extends. In the multistage centrifugal compressor 1 of this embodiment, five impellers 3 are arranged in a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com