Pressure sensor

A pressure sensor and pressure technology, applied in the direction of measuring fluid pressure, instruments, measuring fluid pressure through electromagnetic components, etc., can solve the problems of dynamic performance reduction, dC/dp dynamic performance loss, damage to pressure sensors, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

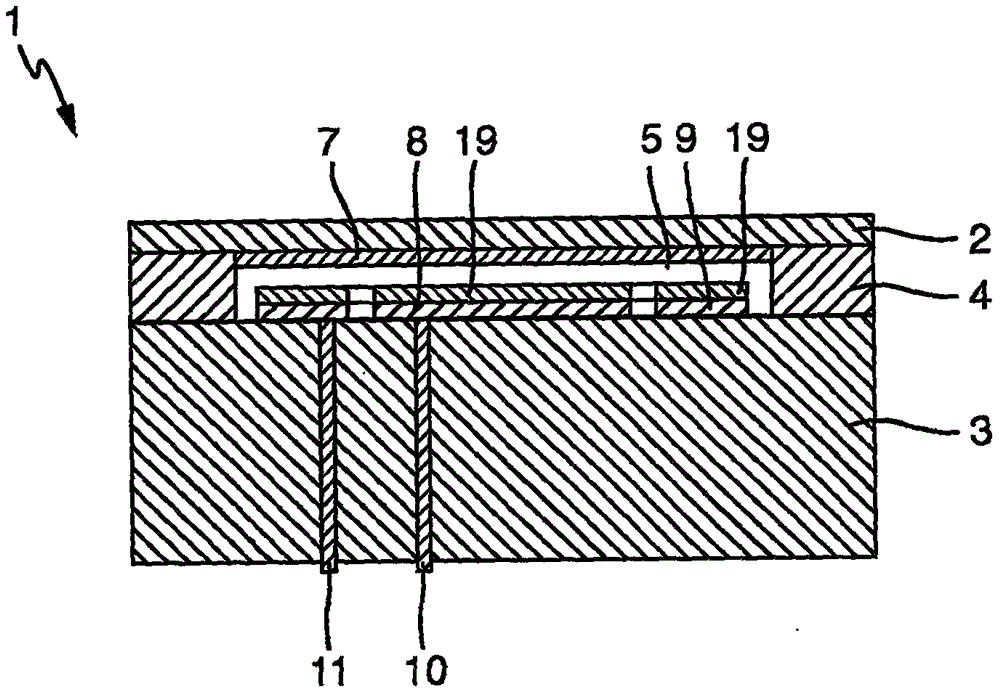

[0028] Such as figure 1 The pressure sensor 1 shown comprises a disc-shaped ceramic measuring diaphragm 2 which is connected in a pressure-tight manner along a circumferential joint 4 to a relatively rigid disc-shaped ceramic counter body 3 , whereby a measuring cavity 5 is created between the counter body 3 and the measuring diaphragm 2 . The measuring diaphragm and the counterpart contain corundum in particular. The joints especially comprise reactive brazes, such as Zr-Ni-Ti reactive brazes or glass.

[0029] The measuring diaphragm has a diaphragm electrode 7 across its entire mating body surface, for example comprising a metal layer, especially a Ta layer, wherein the electrode diameter is 2R, where R is the radius of the flexible region of the measuring diaphragm, corresponding to the inner radius of the joint. On the counterpart surface on the side of the measuring diaphragm, a central disc-shaped measuring electrode 8 is arranged, surrounded by a disc-shaped referenc...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap