Paving and soil-covering integrated machine of mulching film

An all-in-one machine and mulching technology, which is applied in sowing, botany equipment and methods, gardening, etc., can solve the problems of not having a laminated film structure, lowering the laying speed, and raising the mulch, so as to improve the tension, lay flat, and change strong effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

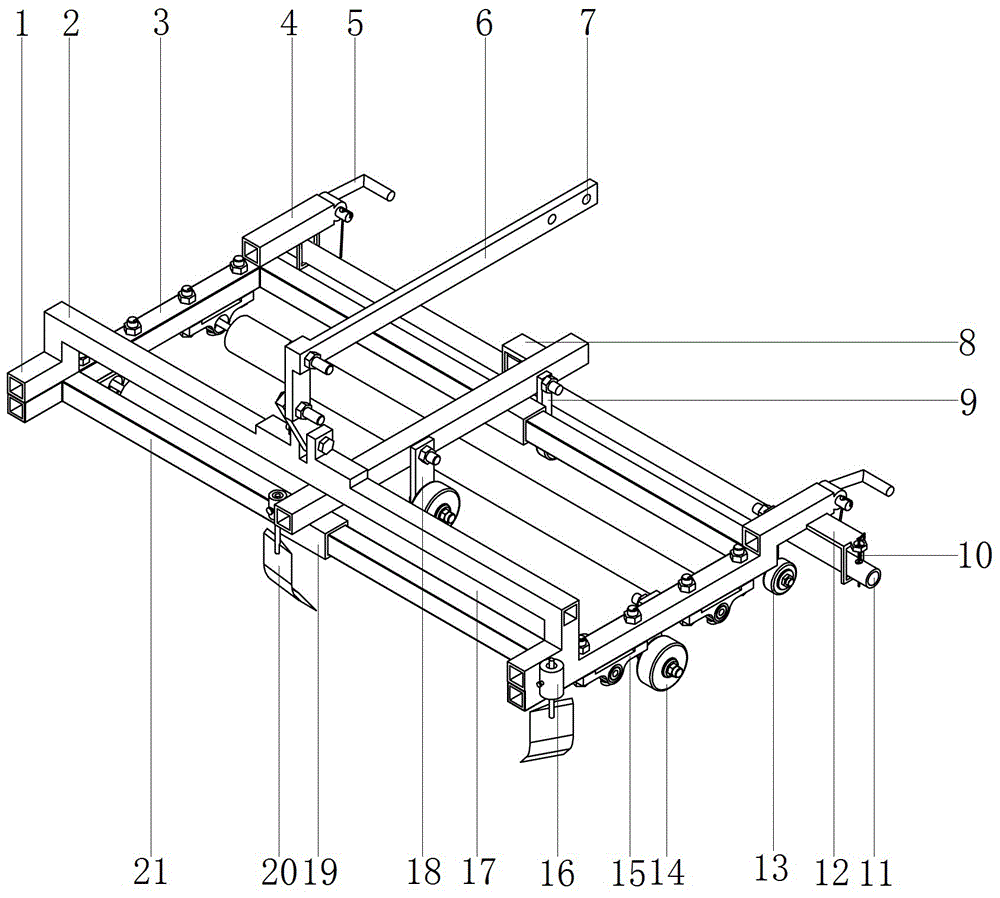

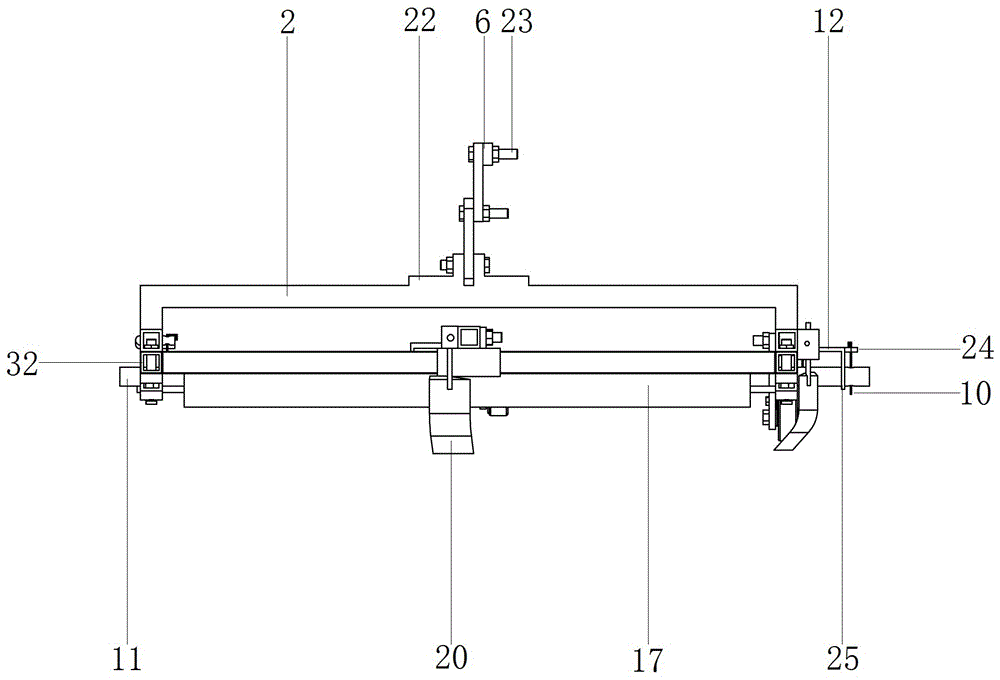

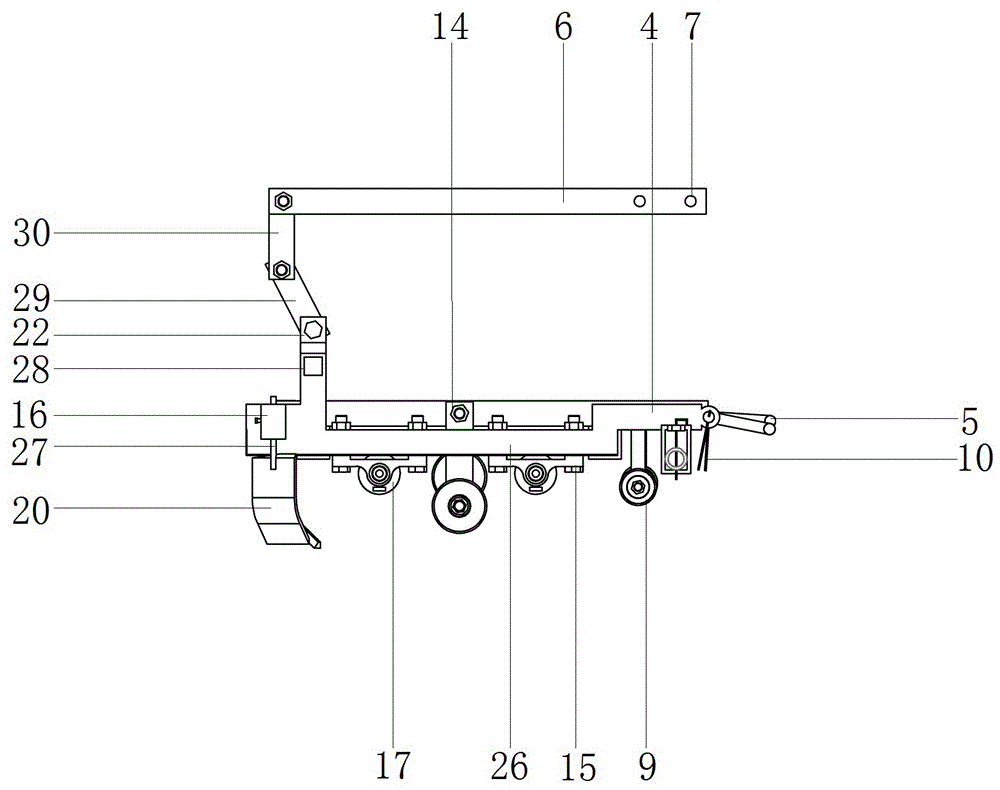

[0035] Such as Figure 1 to Figure 11 An integrated machine for mulch laying and soil covering is shown, which includes a main frame 3, a rear bearing block 1, a rear hook traction device, a large wheel set 18, a small wheel set 9, a distance-adjusting beam 33, a sliding cylinder 19, and a first-stage laminating roller 39. Secondary laminating roller 38, laminating roller lug 15, soil covering device, front bearing block 4, mulching sleeve hanging ring, front hooking traction device, mulching rod 11, top surfaces on both sides of the rear end of the main frame 3 A rear bearing block 1 is provided, and the tops of the two rear bearing blocks 1 are respectively connected to the corresponding structures of the rear articulated traction device. Lamination roller 38, the two ends of the secondary lamination roller 38 are installed on the end of the main frame 3 close to the rear hooking traction device through the lamination roller lug 15 respectively, and the two ends of the first...

Embodiment 2

[0037] Such as Figure 1 to Figure 11An integrated machine for mulch laying and soil covering is shown, which includes a main frame 3, a rear bearing block 1, a rear hook traction device, a large wheel set 18, a small wheel set 9, a distance-adjusting beam 33, a sliding cylinder 19, and a first-stage laminating roller 39. Secondary laminating roller 38, laminating roller lug 15, soil covering device, front bearing block 4, mulching sleeve hanging ring, front hooking traction device, mulching rod 11, top surfaces on both sides of the rear end of the main frame 3 A rear bearing block 1 is provided, and the tops of the two rear bearing blocks 1 are respectively connected to the corresponding structures of the rear articulated traction device. Lamination roller 38, the two ends of the secondary lamination roller 38 are installed on the end of the main frame 3 close to the rear hooking traction device through the lamination roller lug 15 respectively, and the two ends of the first-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com