A method for crushing and separating fused magnesia

A technology of fused magnesia and separation method, which is applied in the direction of grain processing, etc., can solve the problems of reducing product micro-powder content, unreasonable structure, high content of micro-powder in products, etc., and achieve the goal of improving production environment, simple structure and excellent fluidity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

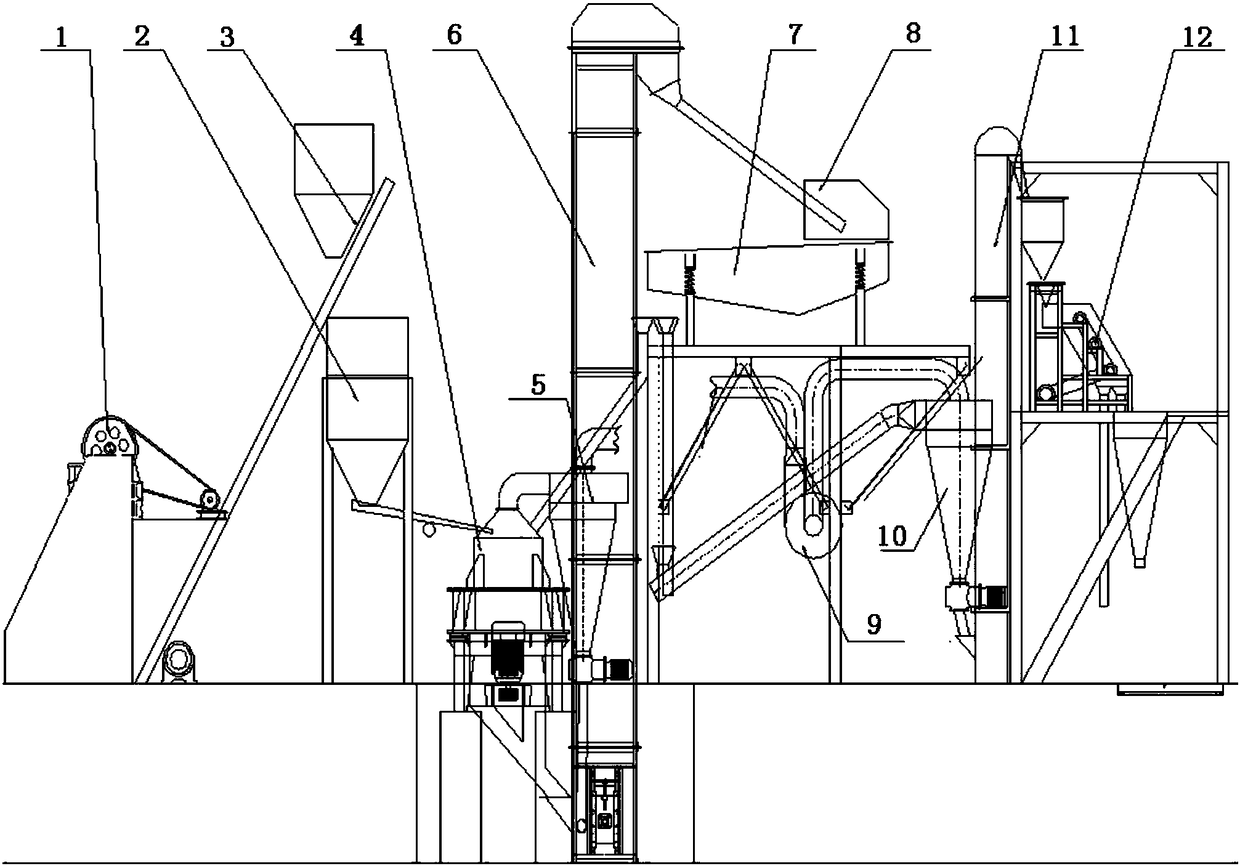

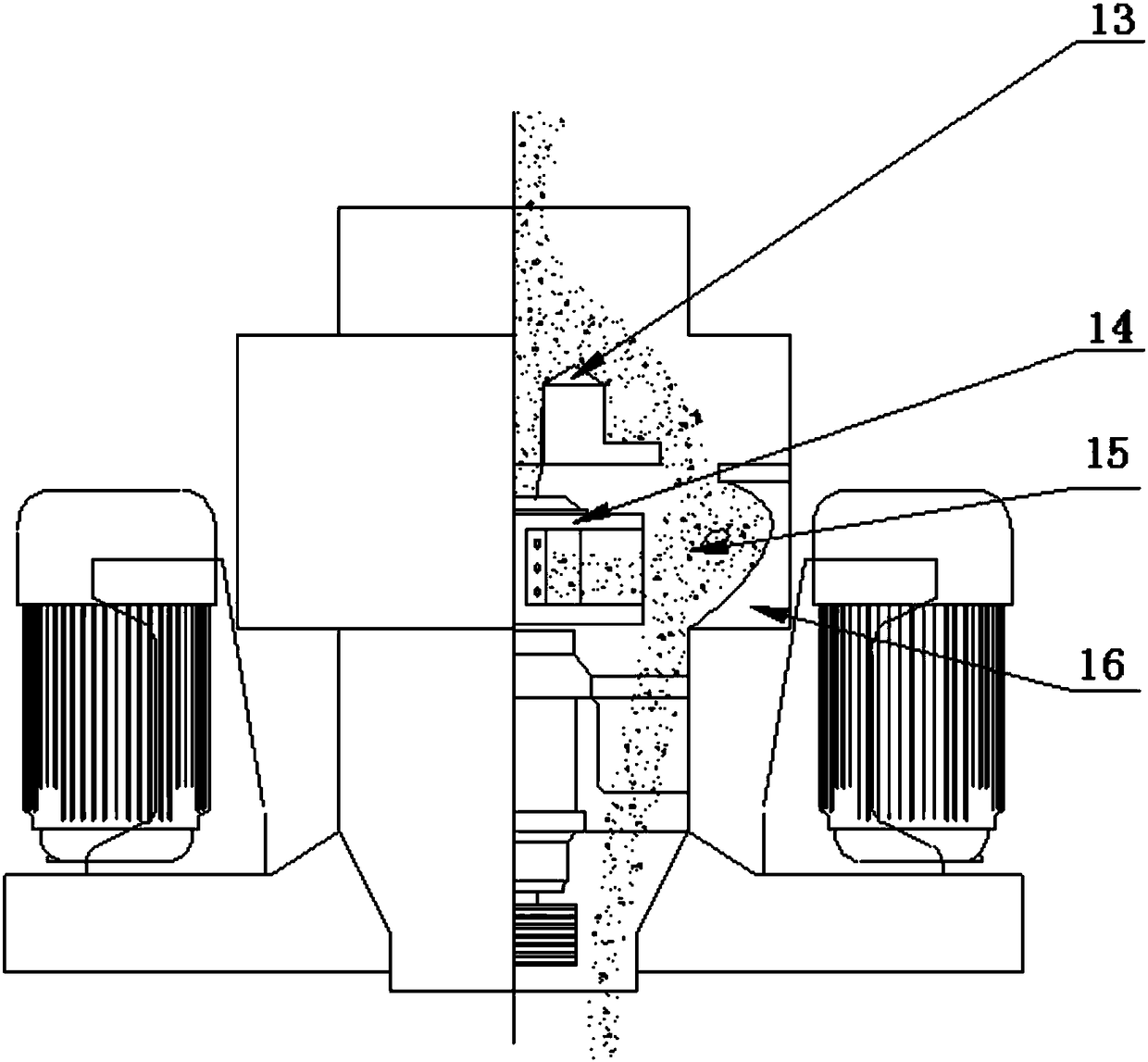

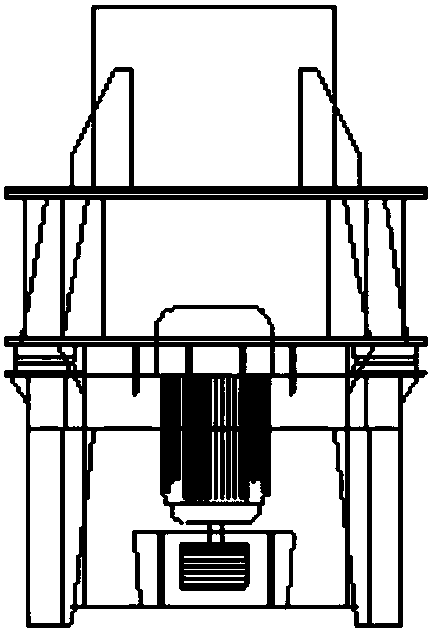

[0040] This embodiment discloses a method for crushing and separating fused magnesia, using such as Figure 1-7 The fused magnesia crushing and separating system includes a jaw crusher 1, a first hoist 3, a silo 2, a vibrating feeder, a vertical shaft impact crusher 4, a first cyclone separator 5, a linear vibrating screen 7, Second cyclone separator 10 and magnetic separator 12 .

[0041] Between the jaw crusher 1 and the vertical shaft impact crusher 4, a first hoist 3, a material bin 2 and a vibrating feeder are sequentially arranged. Specifically, the outlet of the jaw crusher 1 is set at the lower end of the first hoist track, and a silo matching the outlet of the loading crawler is set below the upper end of the first hoist track, and the silo The outlet is arranged above the vibrating feeder, and the outlet of the vibrating feeder communicates with the inlet of the vertical shaft impact crusher. The vibrating feeder can realize uniform feeding.

[0042] The outlet of...

Embodiment 2

[0054] This embodiment discloses a crushing and separating system for fused magnesia. A cyclone separator, the inner wall of the cyclone near the dust-laden air inlet of the cyclone separator is provided with a plurality of inserting plates along the circumference, and the inserting plates are inclined to the direction of wind flow. Compared with ordinary cyclone separators, which are difficult to separate due to piles of particles, the cyclone separator with insert plate in this embodiment can break up the piled particles, which is beneficial to separation.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com