Vertical shaft type automatic mold opening device and injection molding machine for a disc type injection molding machine

An injection molding machine and disc-type technology, which is applied in the field of injection molding machinery, can solve the problems of mold personal safety threats, time-consuming and labor-intensive processes, and poor quality of mold opening, and achieve the effects of simple and reasonable structure, flexible and convenient operation, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0048] In order to further explain the technical solutions of the present invention, specific examples are given below to illustrate in detail.

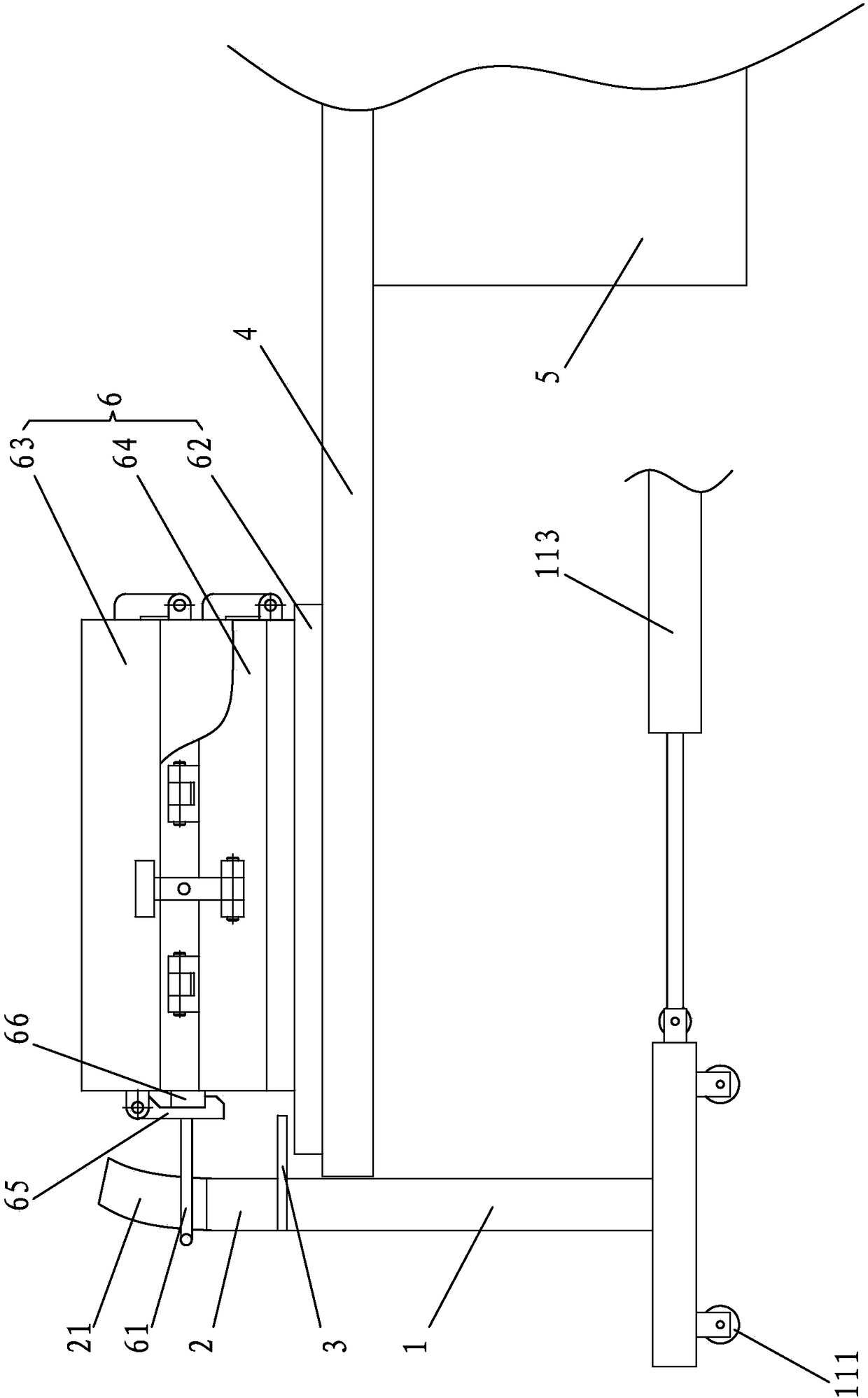

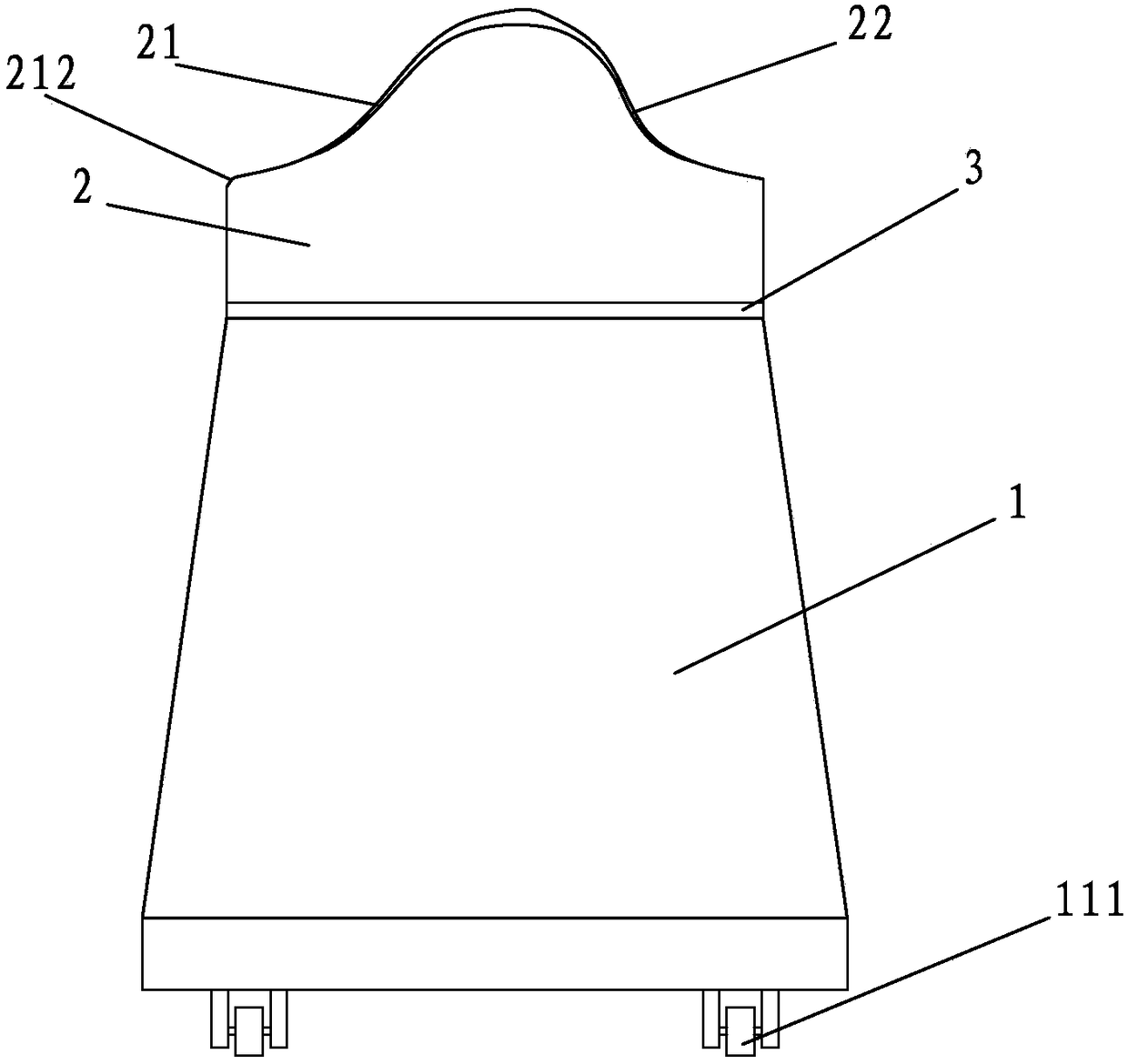

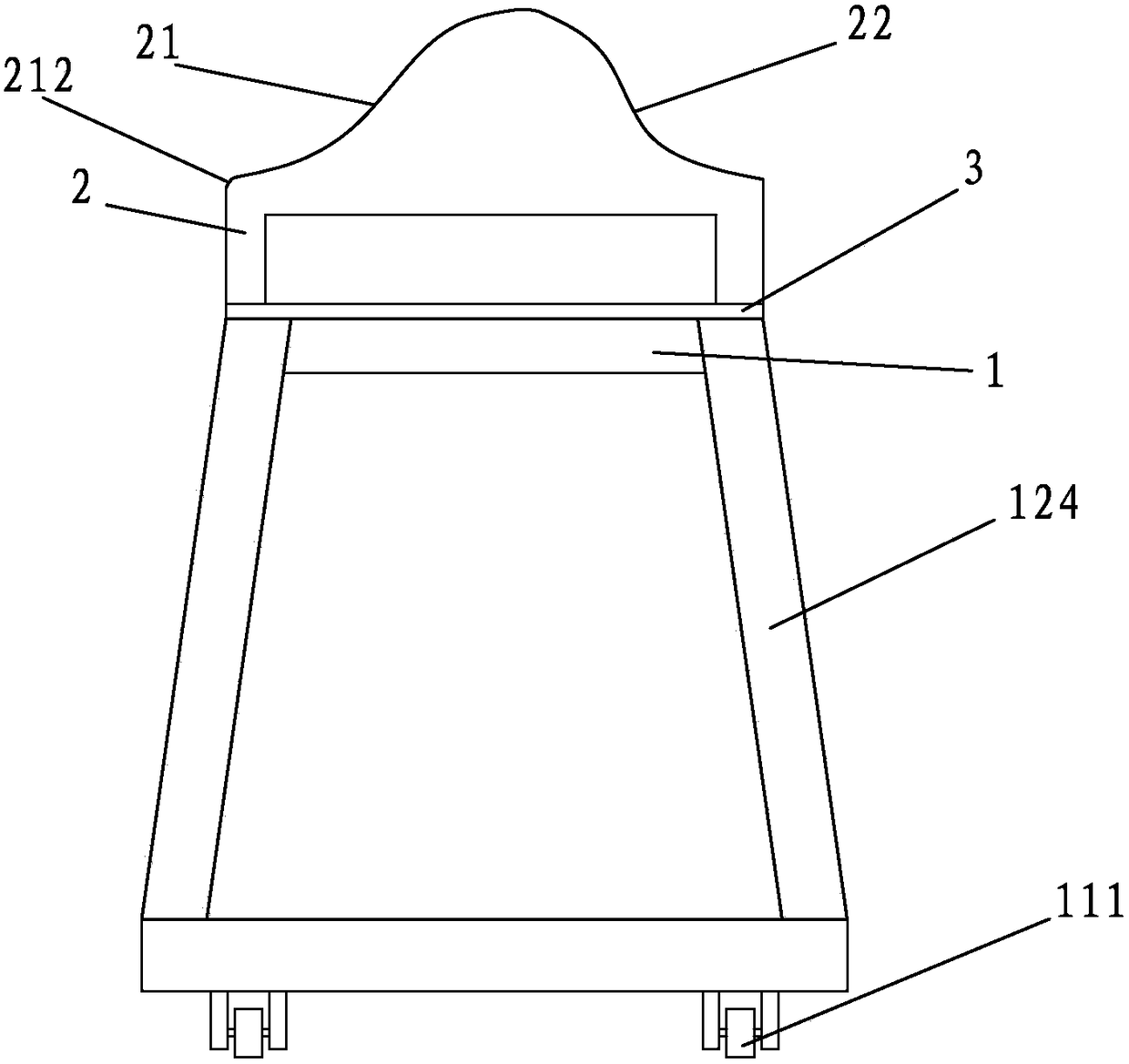

[0049] A vertical shaft type automatic mold opening device of a disc type injection molding machine of the present invention, such as Figure 1-13 As shown, it includes a frame body 1, a mold opening actuator 2 and an anti-lifting device 3.

[0050] The frame body 1 is on the edge of the disc 4 during operation, the mold opening actuator 2 is set on the frame body 1 and corresponds to the buckle handle 61 of the mold 6, and the anti-lifting device 3 is set on the frame body 1 or the mold opening actuator 2 Prevent the mold bottom plate 62 from lifting; the mold opening actuator 2 has an uphill bevel 21 that meets the buckle handle 62 that moves with the mold 6 (facing the direction that the buckle handle 62 moves) and that is in corresponding sliding contact. The hypotenuse 21 gradually changes from low to high along the rotation di...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com