Cooling apparatus for hot nozzle of injection mould

A technology of injection mold and cooling device, which is applied in the field of plastic mold manufacturing, can solve the problems of reduced efficiency of the hot runner cooling device, uncontrollable temperature around the hot nozzle, inconvenient installation of the hot nozzle, etc., achieve good cooling effect, improve appearance defects, Good cooling effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

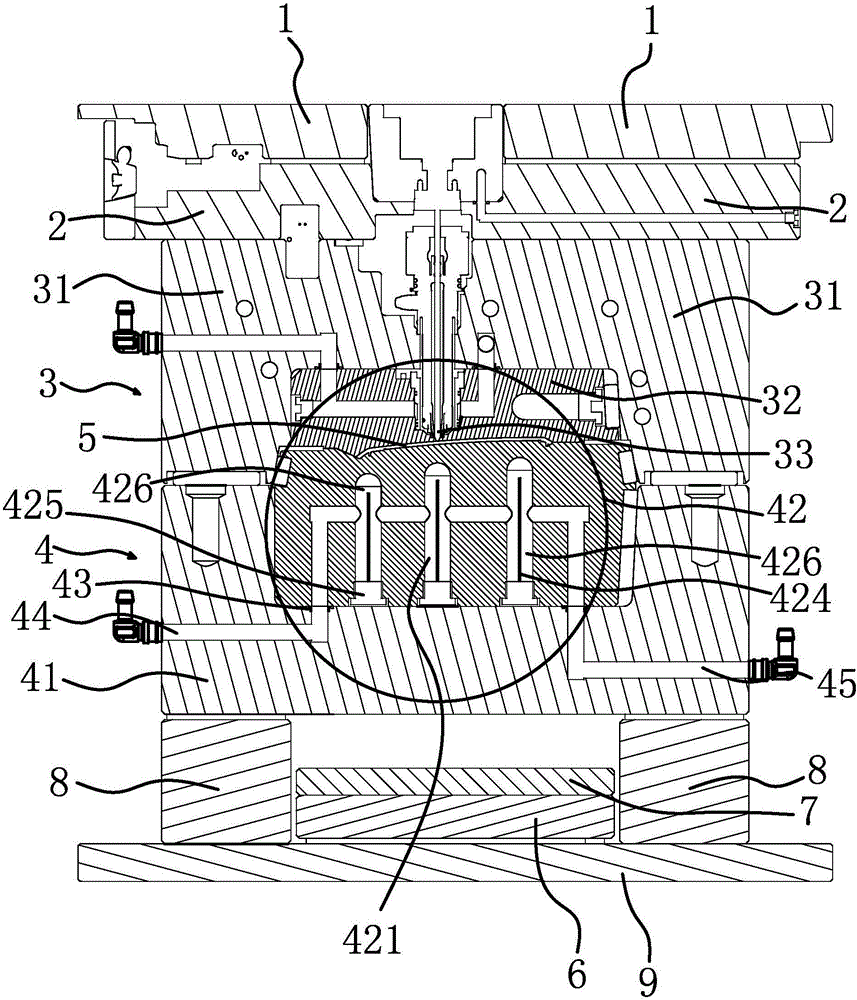

[0039] Such as figure 1 As shown, in the cooling device for the hot nozzle of an injection mold, the injection mold includes a panel 1, a hot runner frame plate 2, a fixed mold 3, a hot nozzle 33 inserted in the fixed mold 3, a movable mold 4, and a bottom needle plate. 6. The needle plate 7, the square iron 8 and the bottom plate 9. The cooling device includes a cooling water well 421, a water inlet passage 44 and a water outlet passage 45 arranged in the movable mold 4.

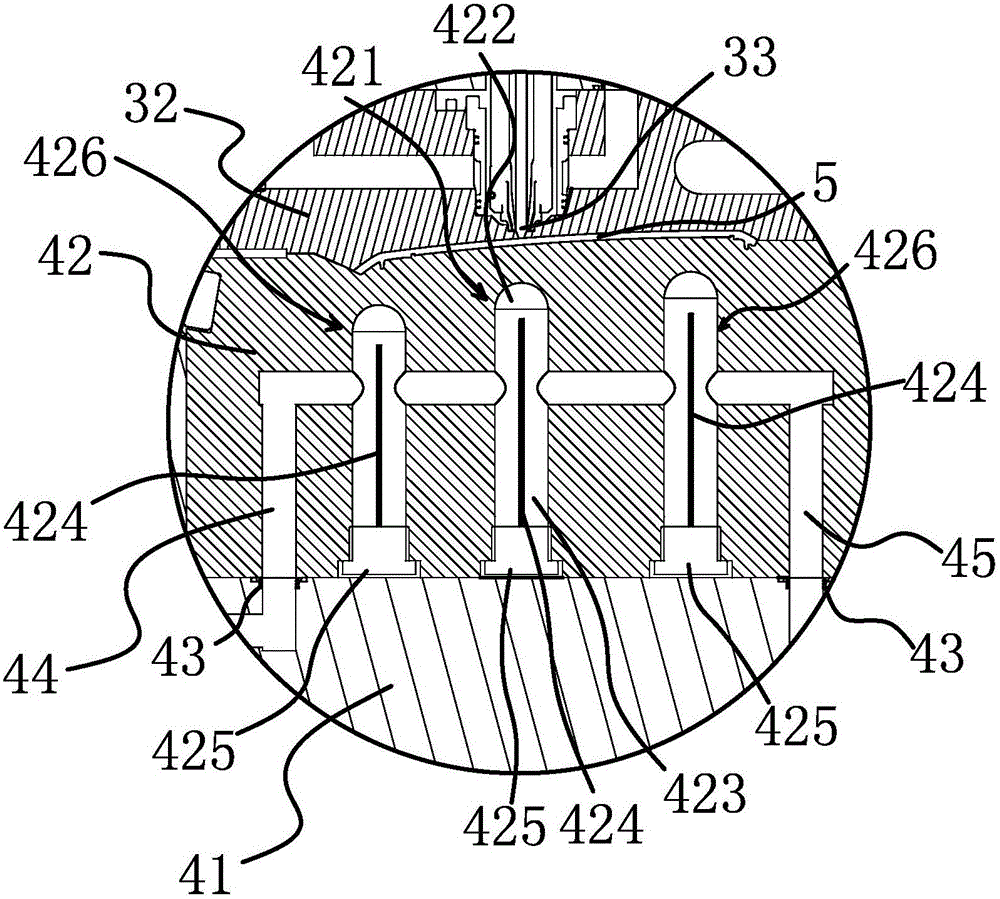

[0040] Specifically, such as figure 1 with figure 2 As shown, the movable mold 4 includes a movable mold plate 41 and a movable mold insert 42. The cooling water well 421 is arranged in the movable mold insert 42, and the water inlet passage 44 and the water outlet passage 45 are both located in the movable mold 4 insert and the movable mold plate 41. , And the driven template 41 is connected to the mold temperature machine when it passes through. The upper part of the cooling water well 421 is a cooling cavi...

Embodiment 2

[0050] The structural features of the cooling device for the injection mold hot nozzle of this embodiment are basically the same as those of the first embodiment. The difference is that the guide is a water-carrying pipe, one end of the water-carrying pipe is provided with a cooling port, and the cooling port is arranged in the cooling cavity In 422, one side of the water conveying pipe is provided with a water conveying port, which is connected to the water inlet channel 44. The water conveying pipe is arranged in the cooling water well 421 and connected to the movable mold 4, and the water conveying port is connected to the water inlet channel 44 through which the cooling water passes The water inlet channel 44 is guided from the water port to the water pipe, and the cooling water reaches the cooling port under the action of water pressure. At this time, the cooling port is opened in the cooling cavity 422, so that the cooling water can fill the cooling cavity 422. , The water...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com