Energy-saving steel structure welding equipment

A welding equipment and steel structure technology, applied in the field of steel structure welding, can solve problems such as air pollution and biological damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

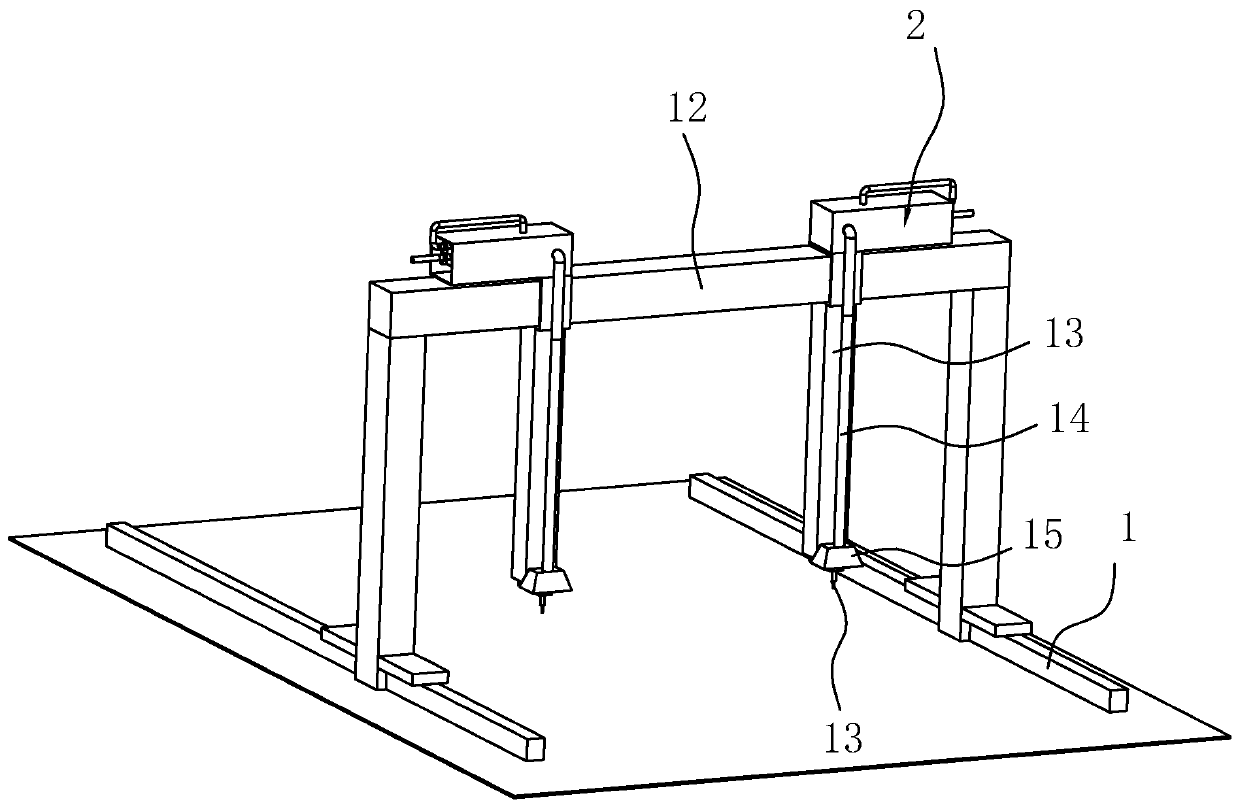

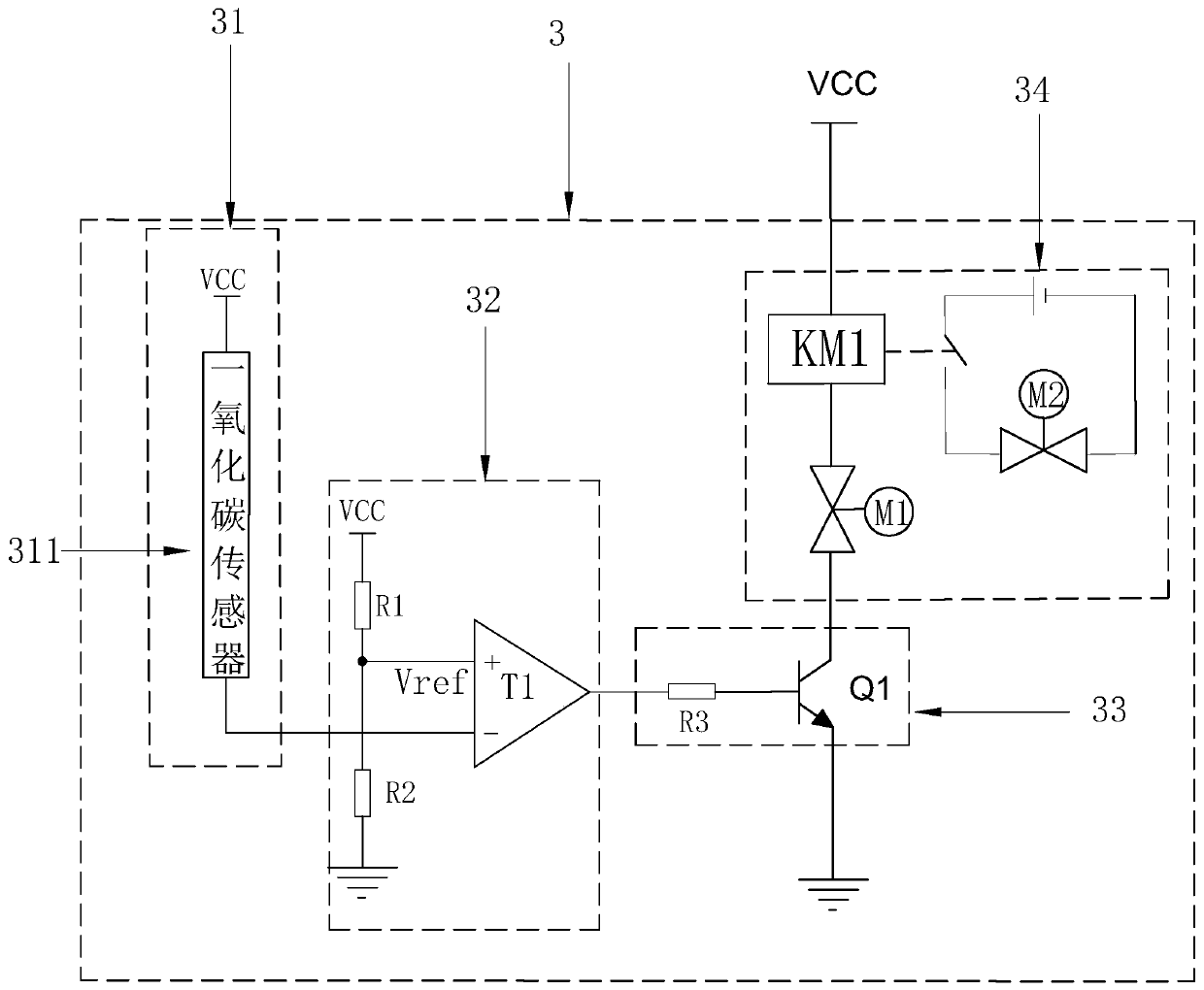

[0036] An energy-saving steel structure welding equipment, see figure 1 and figure 2 , including the slide rail 1, the top of the slide rail 1 is slidably connected to the gantry 11, the top of the gantry 11 is slidably connected with two positioning blocks 12, the bottom of the positioning block 12 is fixed with a welding head 13, and the positioning block 12 is vertical An air extraction duct 14 is provided in the direction, the bottom of the air extraction duct 14 is fixed with an air extraction hood 15, and the top of the positioning block 12 is provided with a cleaning device 2 for processing the smoke and gas extracted by the air extraction duct 14; After welding, the fumes generated by welding enter the cleaning device 2 through the hood 15 and the duct 14. The cleaning device 2 treats the particulate matter and gas in the fumes to reduce harmful gases from being discharged into the air.

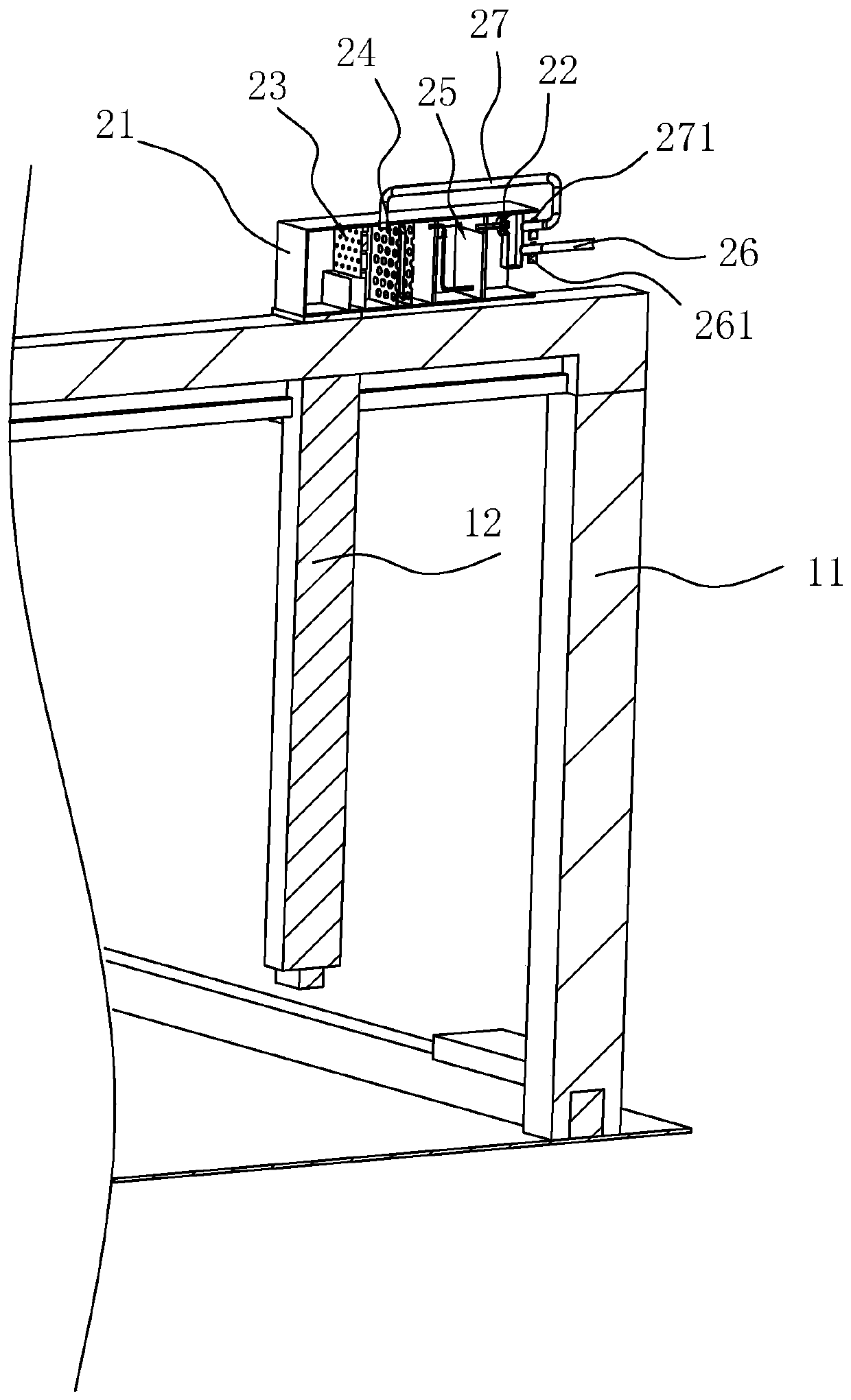

[0037] see figure 2 and Figure 4 , the cleaning device 2 includes a positio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com