A screen printing device with inkjet printing and its control method

A technology of screen printing and inkjet printing, used in screen printing machines, general parts of printing machinery, printing and other directions, can solve the problems of slow printing speed and low printing accuracy, and achieve fast printing speed, high printing accuracy, cost reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

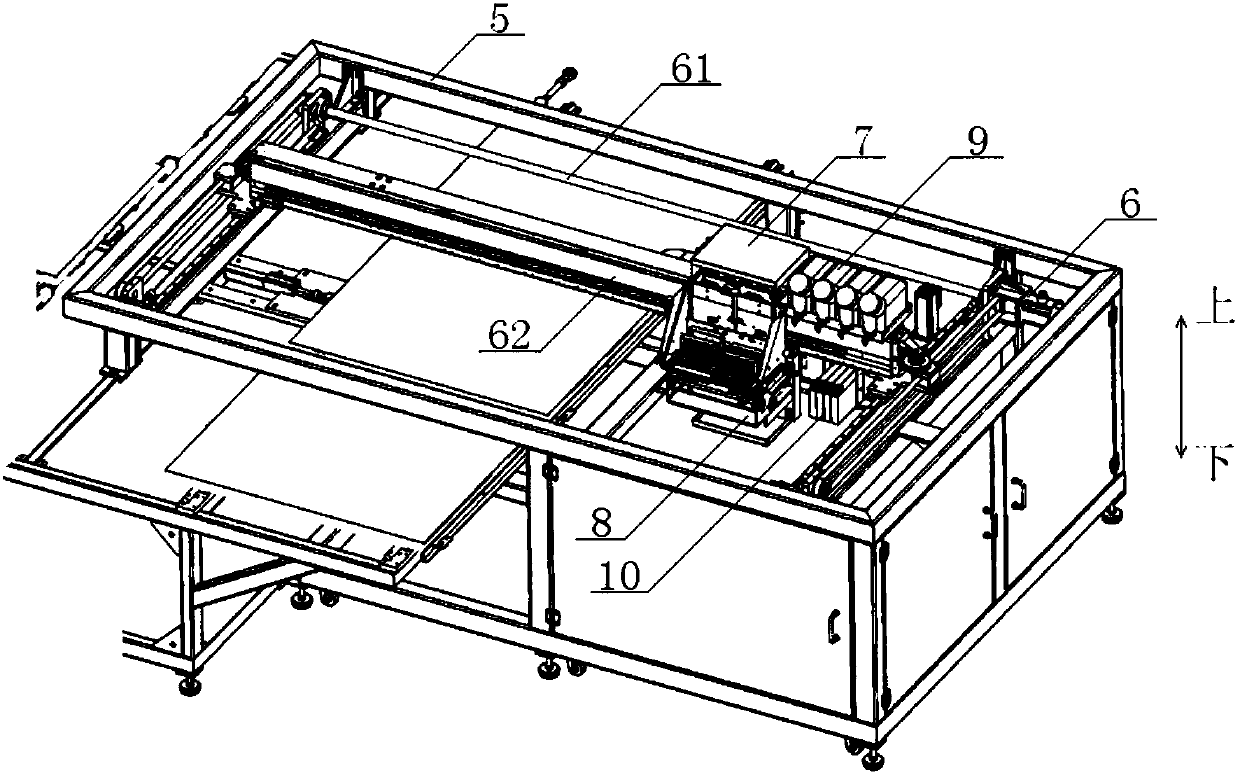

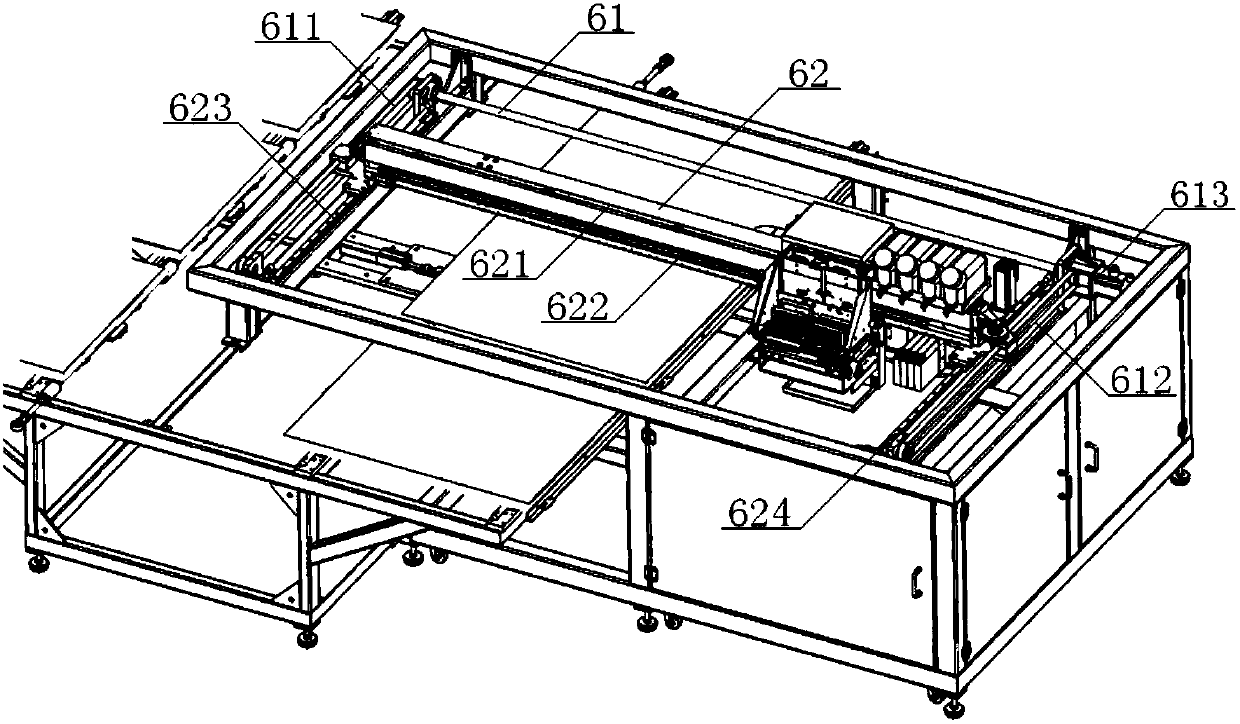

[0073] see Figure 1 to Figure 10, a screen printing device with inkjet printing, comprising a frame 1 and a screen printing device 3 arranged thereon, an inkjet printing device 4, a screen printing device 3, an inkjet printing device 4 and a frame 1 Platen 2 is arranged between, and described inkjet printing device 4 comprises printing frame 5, transmission device 6, inkjet device 7; Described printing frame 5 is internally provided with transmission device 6, and transmission device 6 comprises transmission bar 61 and the printing arm 62, the upper end surface of the printing arm 62 is provided with a No. 1 inkjet guide rail 621, the rear end surface of the printing arm 62 is provided with a No. 2 inkjet guide rail 622, and the left end of the printing arm 62 is connected with the No. 1 belt 611, The lower end of the printing arm 62 left is connected with the No. 1 printing arm guide rail 623, the right end of the printing arm 62 is connected with the No. 2 belt 612, and the...

Embodiment 2

[0076] Basic content is the same as embodiment 1, the difference is:

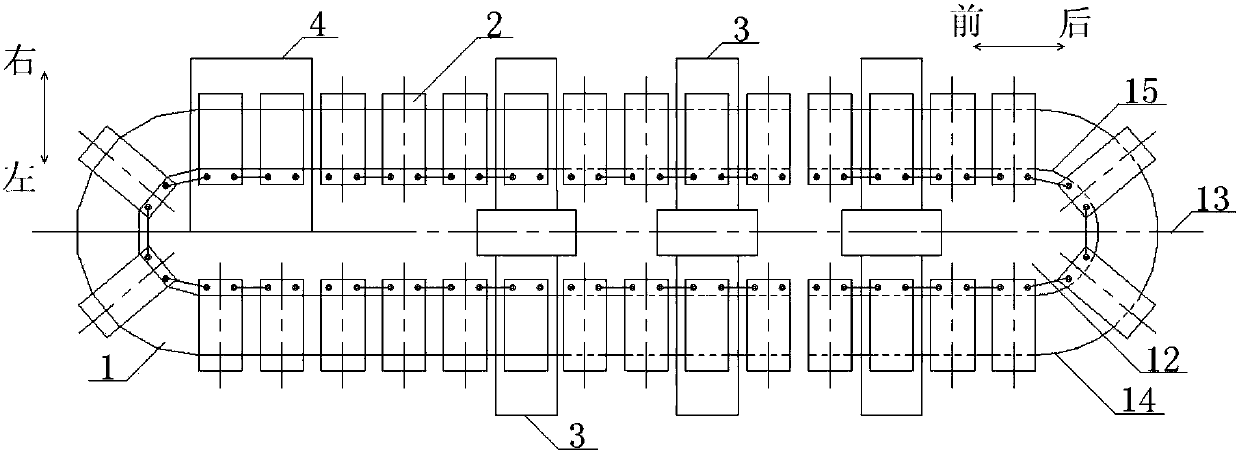

[0077] see Figure 1 to Figure 10 , the frame 1 includes a frame 11 and a panel 12 arranged on its upper end, the panel 12 is elliptical, and the upper end surface of the panel 12 is provided with a No. 1 oval guide rail 14 and a No. 2 ellipse guide rail 15. The center line of No. 1 ellipse guide rail 15 coincides with the center line 13 of panel 12, and platen 2 is arranged between No. 1 ellipse guide rail 14 and No. 2 ellipse guide rail 15, and one end of platen 2 is connected with No. 1 ellipse guide rail 14, The other end of the platen 2 is connected with the No. 2 oval guide rail 15;

[0078] A screen printing device 3 is provided on the panel 12 at the rear of the panel 12. The number of the screen printing devices 3 is six. Three screen printing devices 3 are arranged on both sides, and the screen printing devices 3 on the left and right sides of the centerline 13 are all arranged above the table 2...

Embodiment 3

[0080] Basic content is the same as embodiment 1, the difference is:

[0081] see Figure 1 to Figure 10 , the printing frame 5 includes a No. 1 frame 51 and a No. 2 frame 52 parallel to each other, and the left end of the No. 1 frame 51 is connected with the frame guide rail 16 arranged on the center line 13 through two No. 1 vertical beams 53, The right end of No. 1 frame 51 is connected with the right end of No. 2 frame 52 by No. 2 vertical beam 54, and the left end of No. 2 frame 52 is connected with the right end of frame 11, and the lower end of No. 2 frame 52 is provided with bottom roller 55 and free lifter. Down seat 56, the No. 1 vertical beam 53 and the No. 2 vertical beam 54 are parallel to each other, and the No. 1 crossbeam 57 vertically connected with the No. 1 vertical beam 53 is arranged between the No. 1 vertical beam 53, and the No. 1 frame 51 is located in a The position on the right side of the No. 1 frame 51 is provided with a No. 2 beam 58 vertically co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com