I-shaped inductor automatic code spraying mechanism

A technology of I-shaped inductor and inkjet printer, which is applied to typewriters, printing and other directions, can solve problems such as errors and low efficiency, and achieve the effect of avoiding errors and improving work efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The invention is used to complete the electrical performance test, direction marking and coding of I-shaped inductors, which can be completed by one machine, which improves the quality of coding and white dots, eliminates the misjudgment rate of good products and defective products, and improves efficiency at the same time .

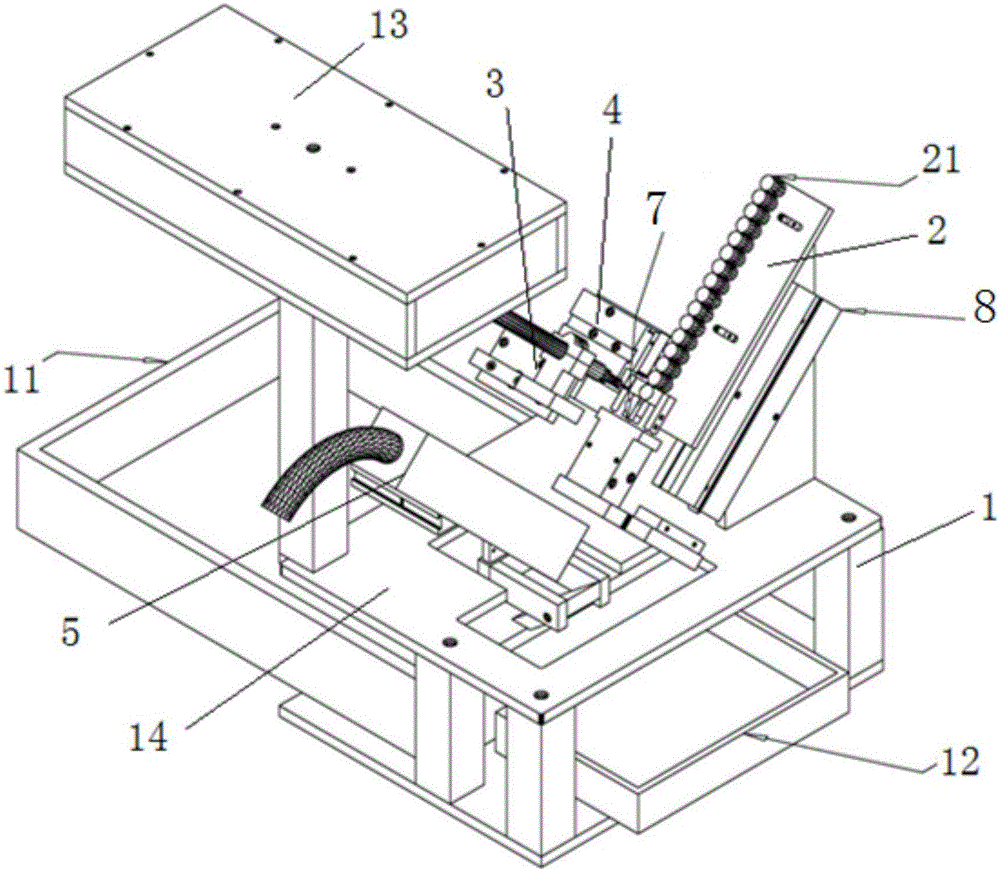

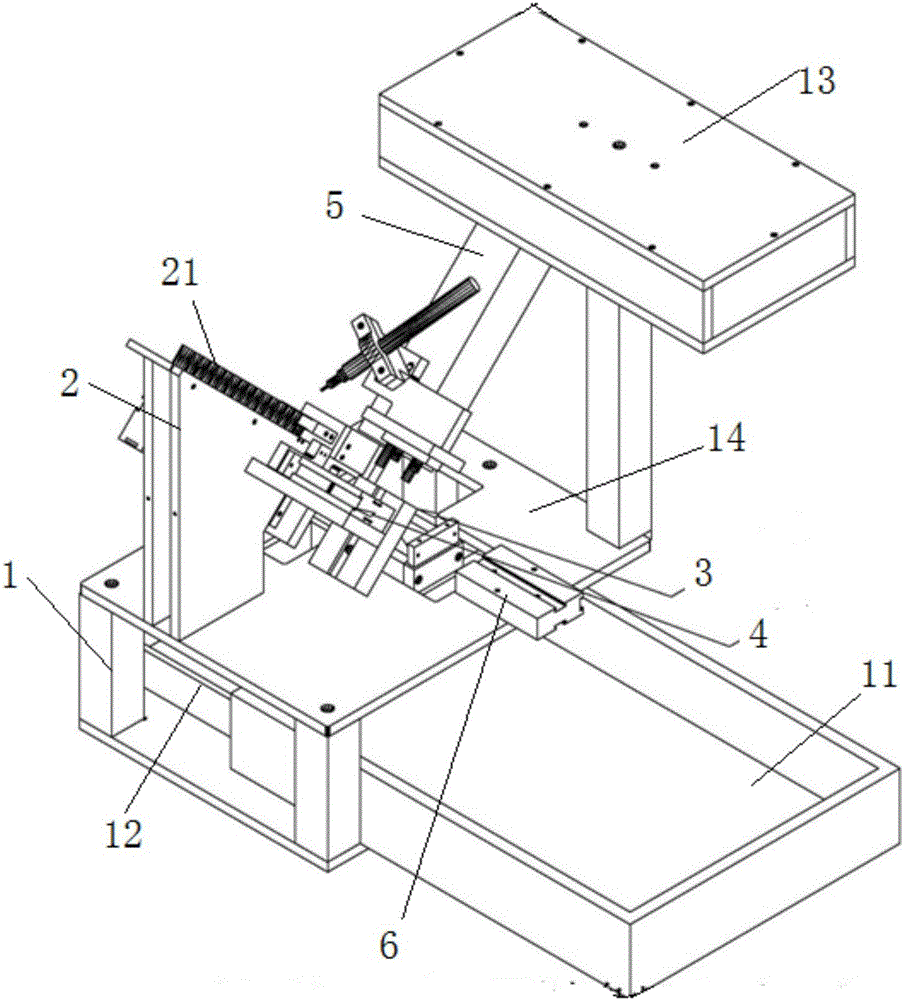

[0012] like figure 1 and figure 2 As shown, an I-shaped inductive coding point and white point test all-in-one machine includes a frame 1, and the frame 1 includes a bottom plate and a top plate 14 arranged above the bottom plate, and a column is arranged between the bottom plate and the top plate 14 support. The frame 1 is provided with an electric control box 13, an inductance transfer device 8, an inductance delivery device 2, an inductance marking device 3, an inductance testing device 4, a coding device 5, a good product inductance screening device 6, and an inductance positioning device above the top plate 14. 7. A classified storage dev...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com