Vacuum adsorption device, diamond adsorption detection device and adsorption control method

A vacuum adsorption and diamond technology, which is used in measurement devices, transportation and packaging, material analysis by optical means, etc., can solve the quality of the ordered arrangement of diamonds, the diamond adsorption rate cannot give specific data, and cannot be monitored in real time. Adjust the diamond adsorption rate and other issues to achieve the effect of technical ingenuity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

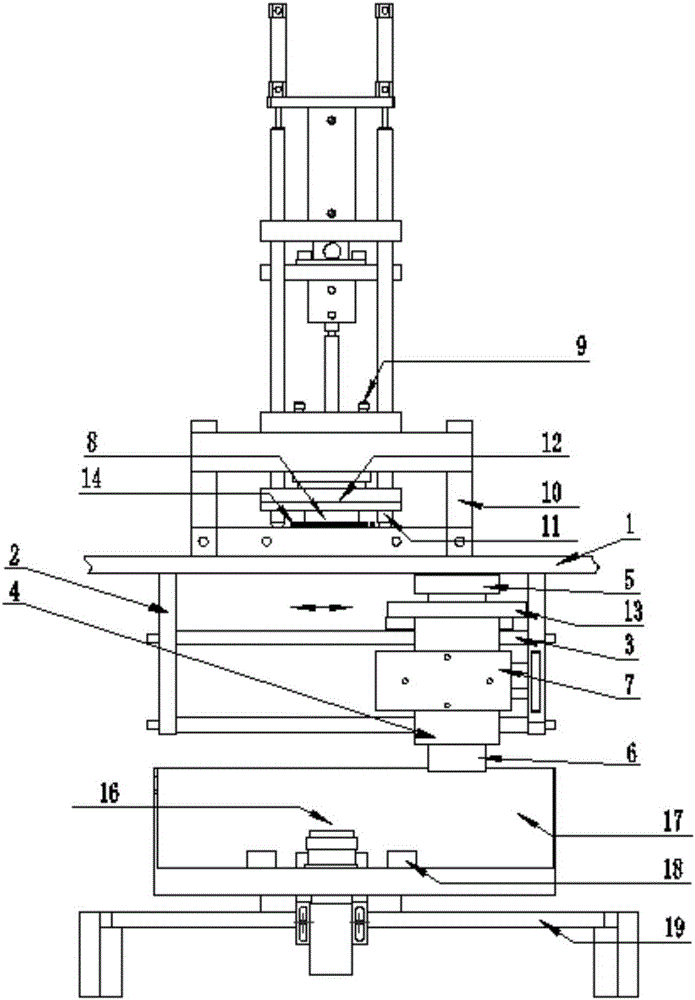

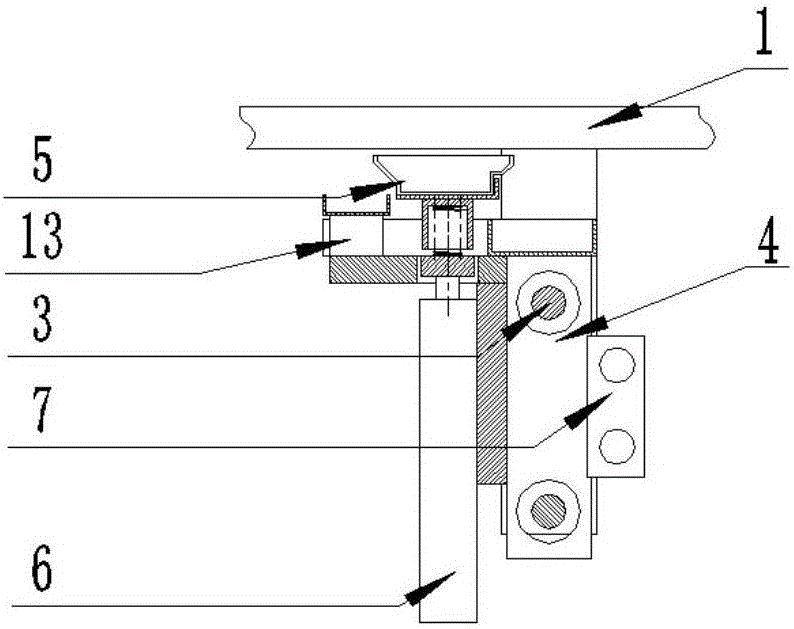

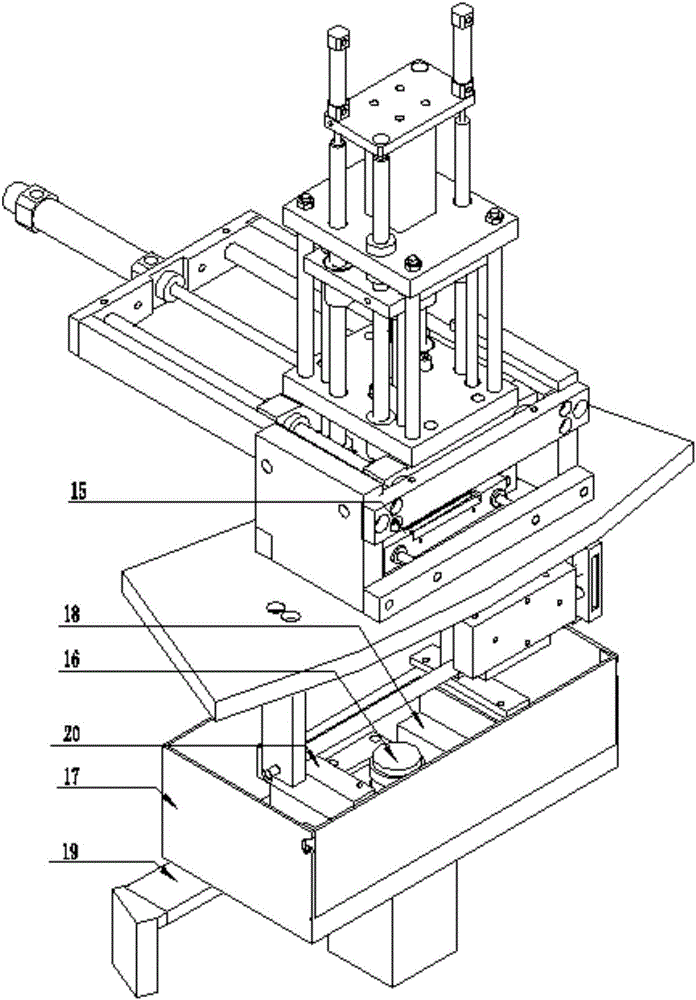

[0038] The technical problem to be solved by the present invention is: with the current production process, there is no way to give specific data on the adsorption rate of diamonds, so that the adsorption rate of diamonds cannot be monitored and adjusted in real time, which will affect the quality of the ordered arrangement of diamonds. The technical idea proposed by the present invention to solve the technical problem is: construct a vacuum adsorption device, set a camera under the adsorption assembly of the vacuum adsorption device, the camera can take pictures of the actual adsorption of diamond on the adsorption assembly, and the diamond By comparing the actual adsorption photos of the diamond with the comparative adsorption photos of the diamond, the adsorption rate of the diamond can be obtained; the adsorption effect of the adsorption component can be judged by the adsorption rate of the diamond, so that the adsorption component can be adjusted in a targeted manner.

[0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com