Elevator safety clamp

A safety gear and elevator technology, used in transportation, packaging, elevators, etc., can solve the problems of small braking adjustment range, reduced safety performance, friction pad wear, etc., to achieve good braking effect, long service life, and braking process. smooth effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

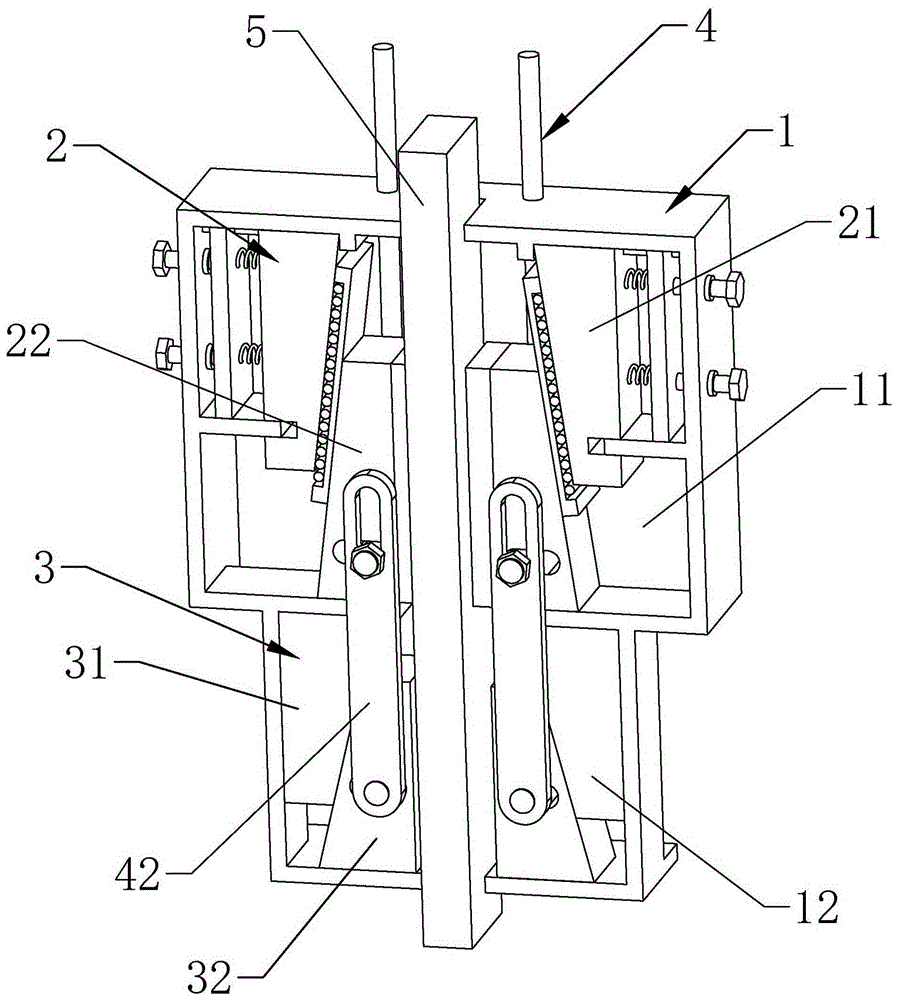

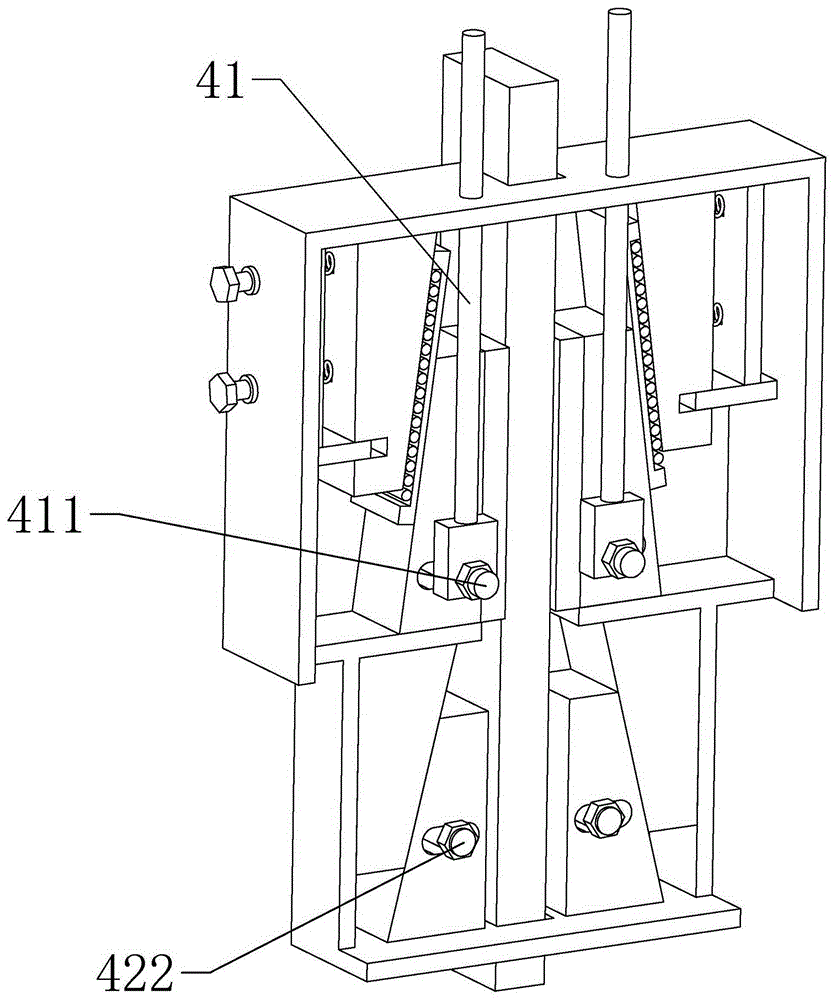

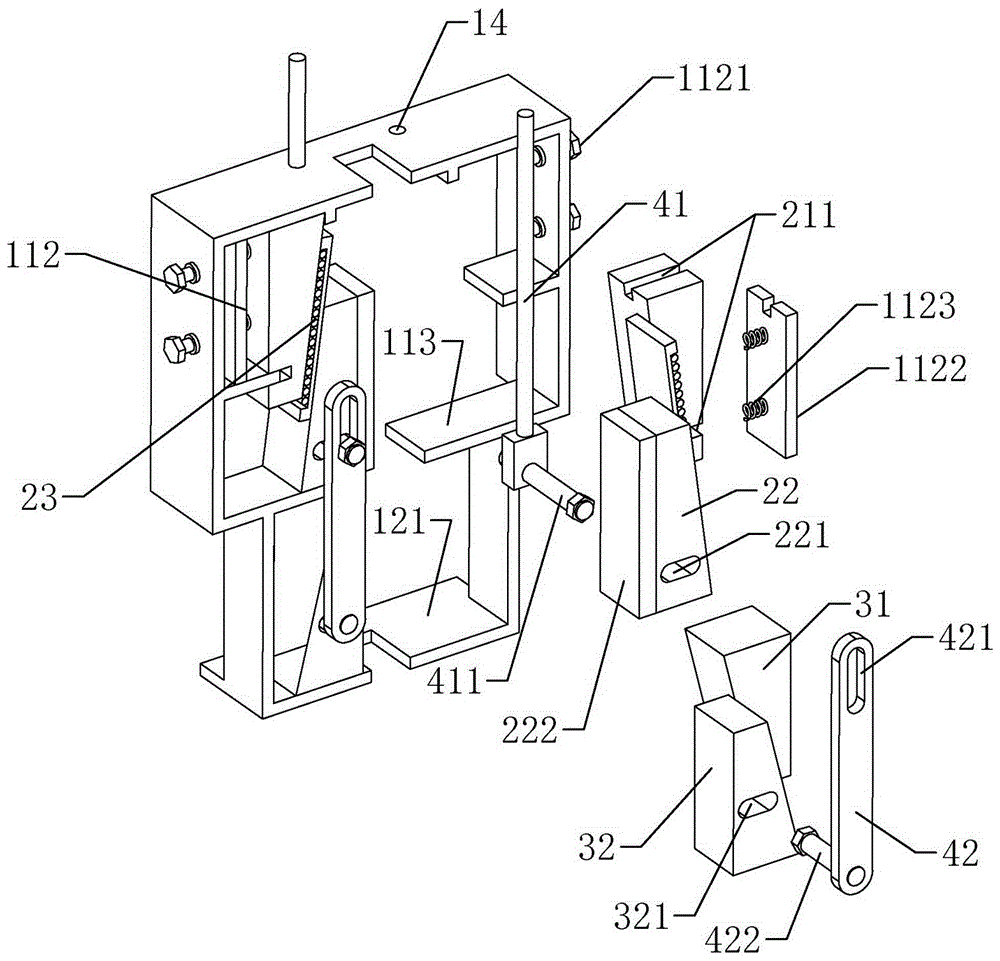

[0033] according to Figure 1 to Figure 4 As shown, an elevator safety gear is characterized in that it includes: a bracket 1, an upper clamp body 2, a lower clamp body 3 and a pull rod 4;

[0034] The bracket 1 includes an upper clamp body cavity 11 and a lower clamp body cavity 12 connected up and down. The center of the bracket 1 is provided with a through groove 13 for the guide rail 5 to pass through. The top of the bracket 1 is provided with a through hole 14 for the upper pull rod 41 to pass through.

[0035] The upper pliers body 2 is arranged in the upper pliers body cavity 11 and includes an upper fixed wedge 21 and an upper movable wedge 22 arranged from outside to inside, and a first horizontal hole 221 is arranged at the lower part of the upper movable wedge 22 .

[0036] The lower pliers body 3 is arranged in the lower pliers body cavity 12 and includes a lower fixed wedge 31 and a lower movable wedge 32 arranged from outside to inside, and a second horizontal ho...

Embodiment 2

[0042] The difference from the above-mentioned embodiment 1 is that a guide piece 23 is provided between the upper fixed wedge 21 and the upper movable wedge 22, and a roller is arranged inside the guide piece 23, and the roller and the slope of the fixed wedge 22 are in contact with each other for Optimize the movement guide of upper movable wedge 22.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com