Hybrid girder cable-stayed bridge closure front girder body pre-bias pushing device

A technology of jacking devices and cable-stayed bridges, which is applied in the direction of cable-stayed bridges, bridges, bridge forms, etc., can solve the problems affecting the quality and safety of the project, and the additional cable force of the short cable exceeds the limit, so as to achieve good environmental protection effect, save materials, Simple operation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

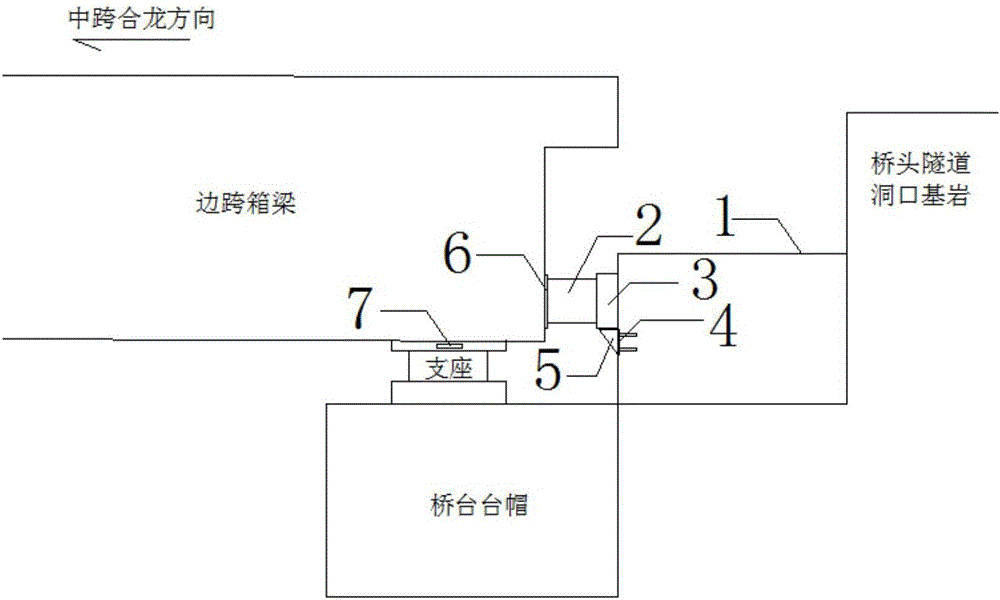

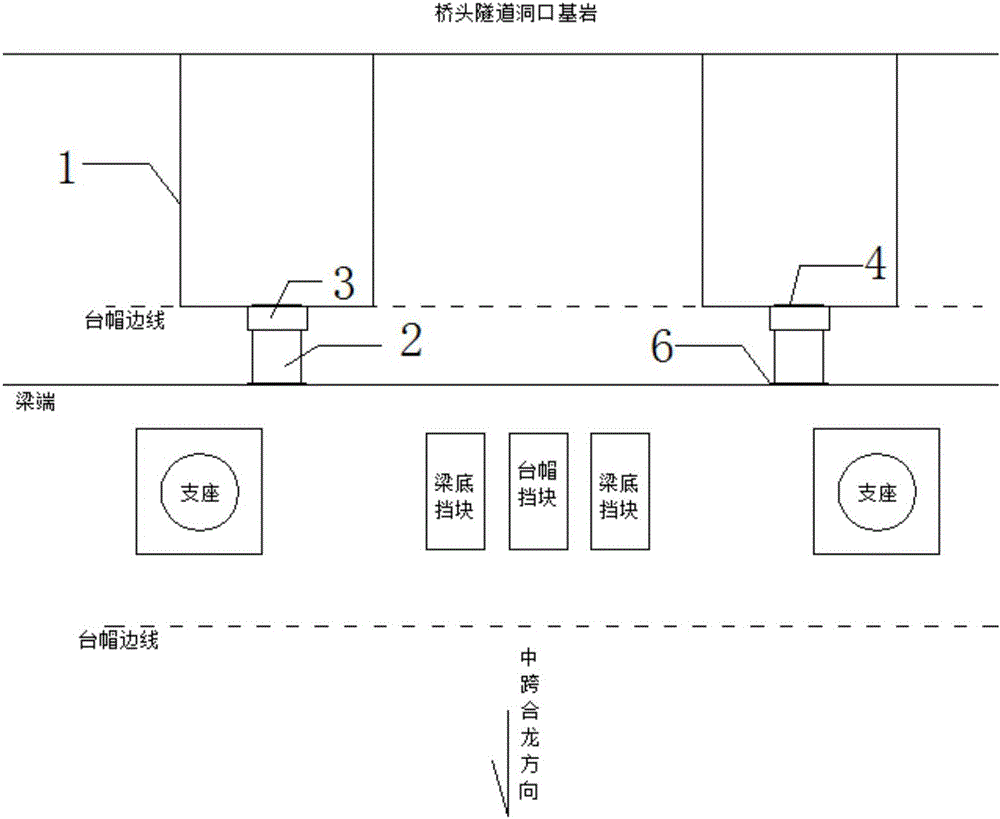

[0022] First, two concrete bases are symmetrically set up with concrete and steel bars at the end of the abutment girder body, and steel plates are pre-embedded in the base corresponding to the beam body pushing position (web plate), and triangular corbel supports are welded on the pre-embedded steel plates, and will be used The force transmission column made of steel plate is placed on the support of the corbel, and the jack (500t) is lifted by the lifting device (2t chain hoist). The rear end of the jack is against the force transmission column, and at the same time, place Steel backing plate, after the jacks of the two bases are in place, start the jacks to support the beam body. After calculating the beam pre-deflection and jacking force, start the jack for test jacking, and set up the beam displacement observation device at the same time, that is, use the level instrument to observe the displacement observation marks on the side of the wedge at the bottom of the beam outsi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com