Concrete face board rock-fill dam bed course area moving boundary wall filling construction technique

A technology of concrete face and construction technology, applied in dams, buildings, barrages and other directions, can solve the problem of many cracks in concrete face, and achieve the effect of improving the filling speed of the dam body, high application value, and reducing the amount of processing works.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

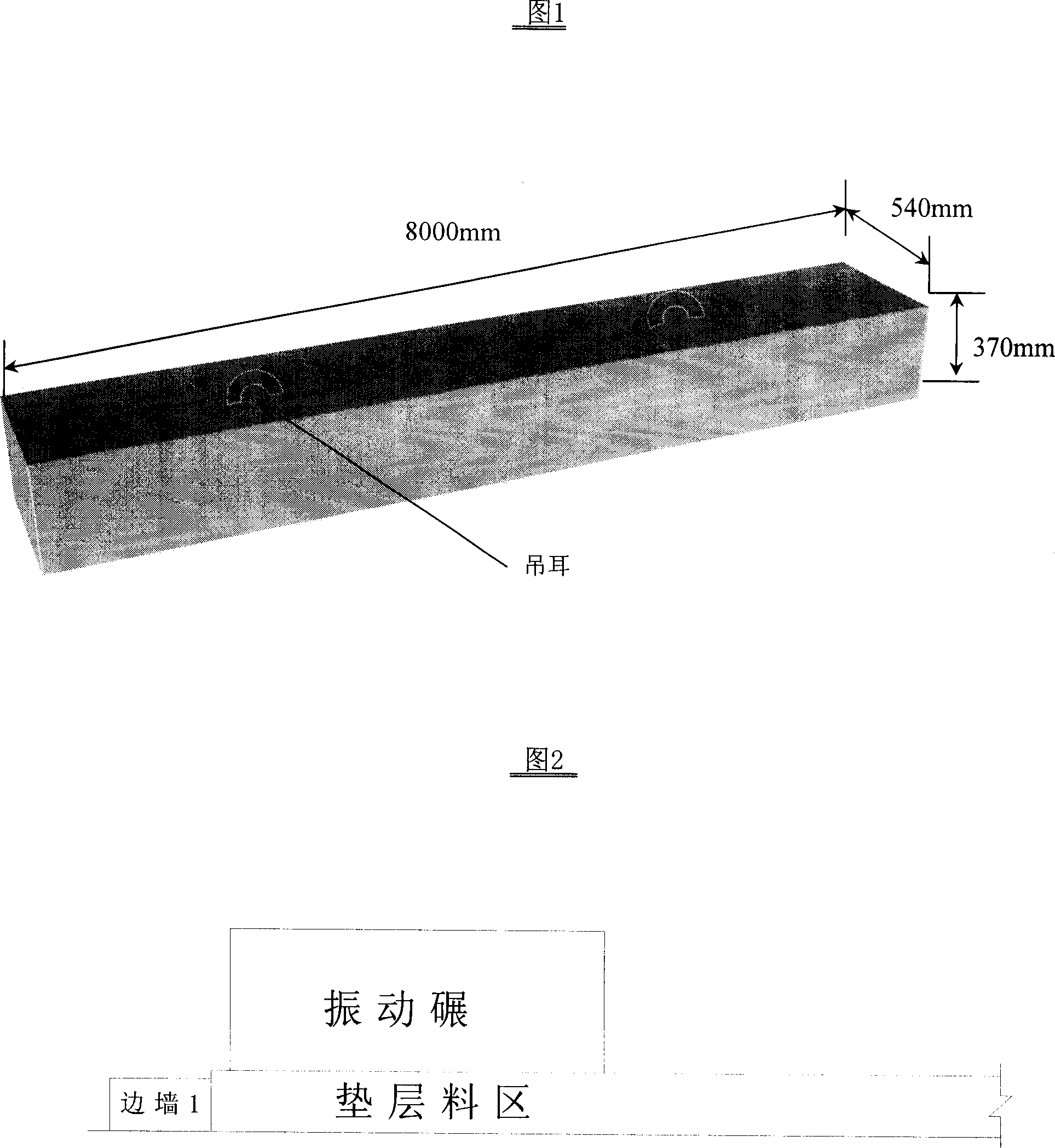

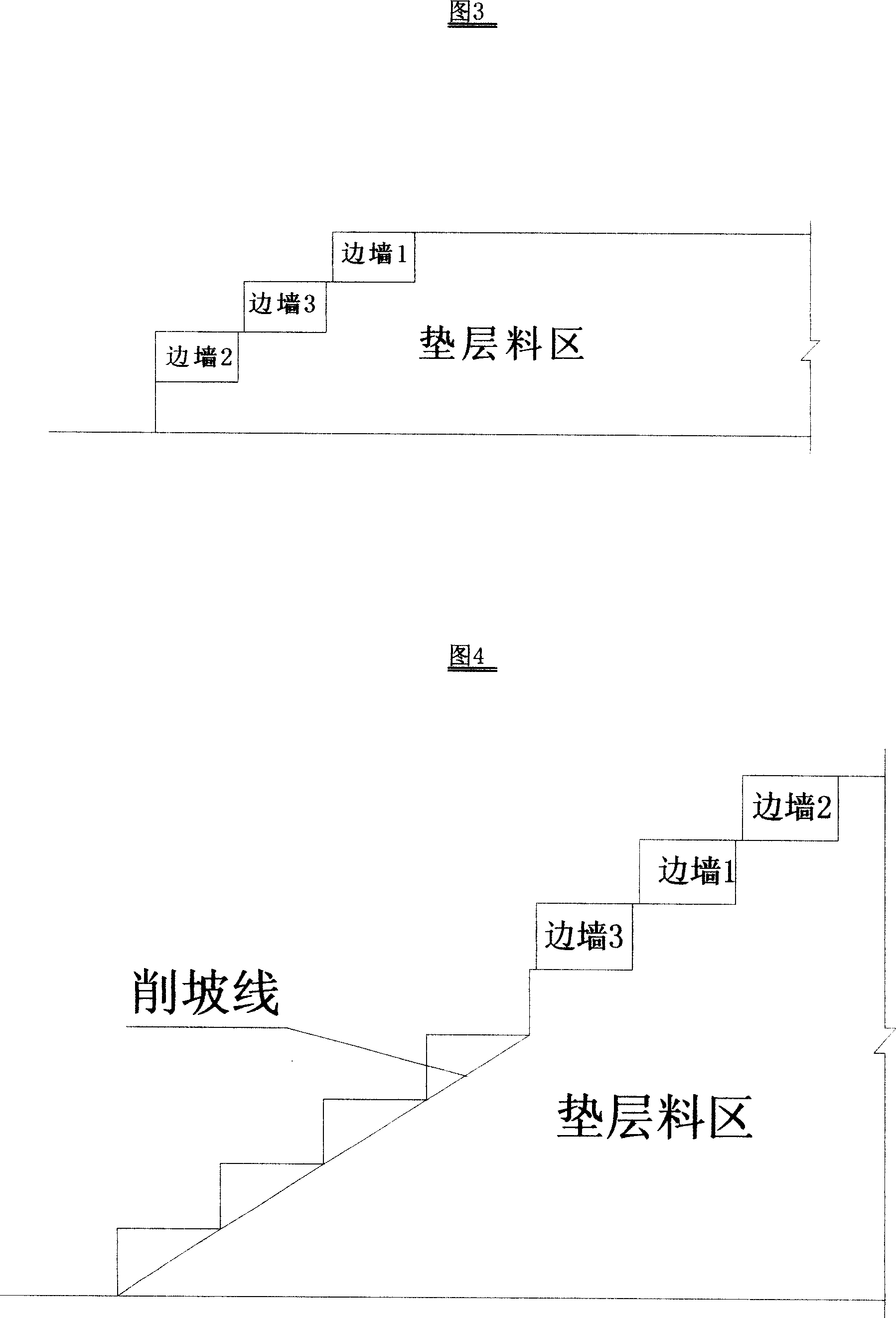

[0014] 1. Mobile side wall design

[0015] The mobile side walls are designed as reinforced concrete prefabricated walls with a rectangular section. The overall strength of the side wall must meet the requirements of installation and stability under vibration and rolling conditions. The height and width of the side wall are related to the thickness of the layered rolling layer of the cushion material, the rolling parameters and the upstream slope of the cushion area. In actual construction, the height and width of the wall are designed according to the specific construction parameters. The length of the side wall is determined according to the rolling experiment. When rolling, the wall is stable, and the horizontal displacement is not more than 2cm, so as to ensure the compaction of the cushion material. Two lifting lugs are arranged symmetrically on the top surface of the side wall to facilitate lifting and moving. For example: the cushion material thickness is 43cm, the co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com