Tailing pond capable of achieving repeated stacking

A technology of tailings ponds and accumulation dams, applied in the field of tailings ponds, can solve problems affecting the normal production of enterprises, affecting the enthusiasm of tailings reuse, and increasing the burden on enterprises

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0024] This embodiment is a lead-zinc mining enterprise with a daily processing capacity of 2,000 tons of ore. The repeatable stacking tailings storage capacity built by the technology of the present invention is more than 500,000 cubic meters. The enterprise discharges and excavates alternately in the upstream section and the downstream section according to the production plan. Tailings, tailings are all provided to cement plants as additives.

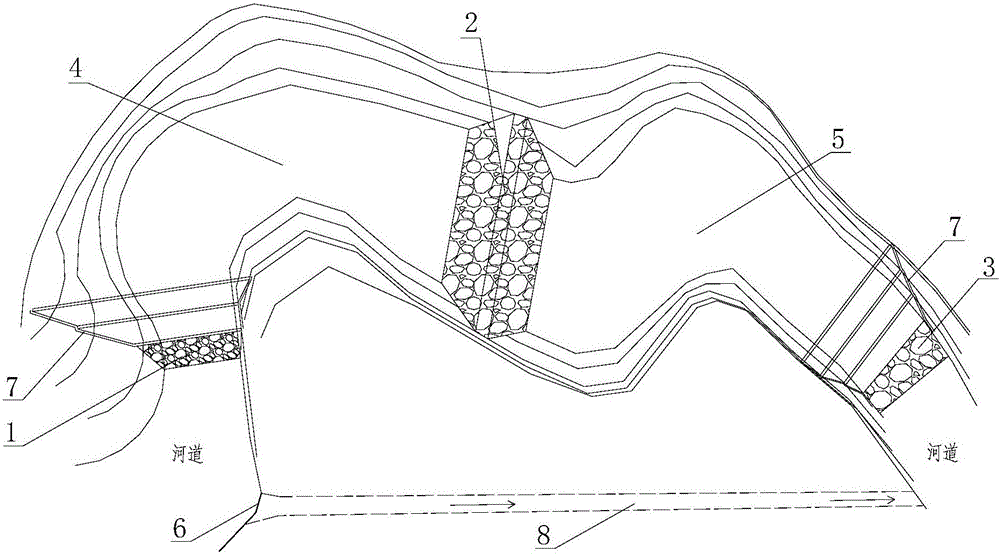

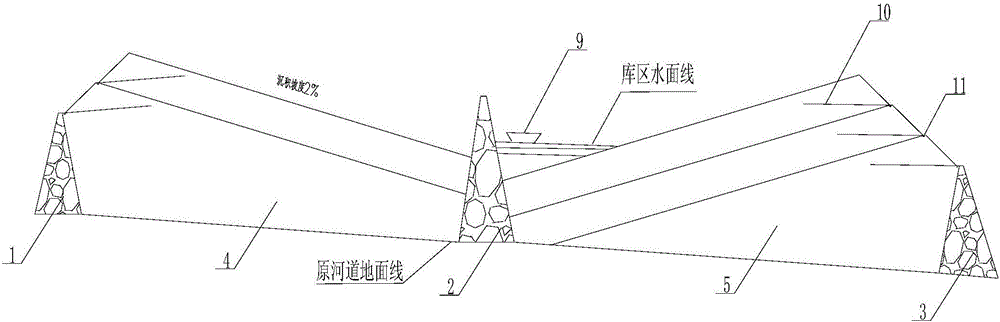

[0025] figure 1 As shown, about 1,000 meters of the river channel in the "C" bend is intercepted, and the grouted masonry gravity type upstream initial dam 1, dividing dam 2 and downstream accumulation dam 3 are built to form a space for stacking tailings, and the upstream is gradually accumulated in later production. When one section of the accumulation dam 4 and the downstream accumulation dam 5 discharge the tailings, the other section excavates the tailings and sends them to the cement plant, and they are carried out mutually, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com