Detachable threaded connection centering device

A threaded connection and disassembly technology, applied in drilling equipment, earth-moving drilling, drill pipe, etc., can solve the problem of centralizers failing to achieve the effect of centralizing and high cost, and achieve the effect of high cost performance, easy to move and easy to replace

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

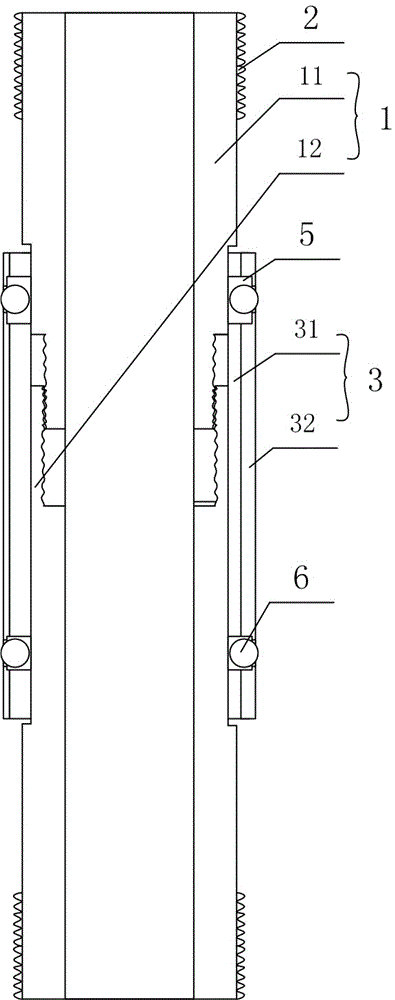

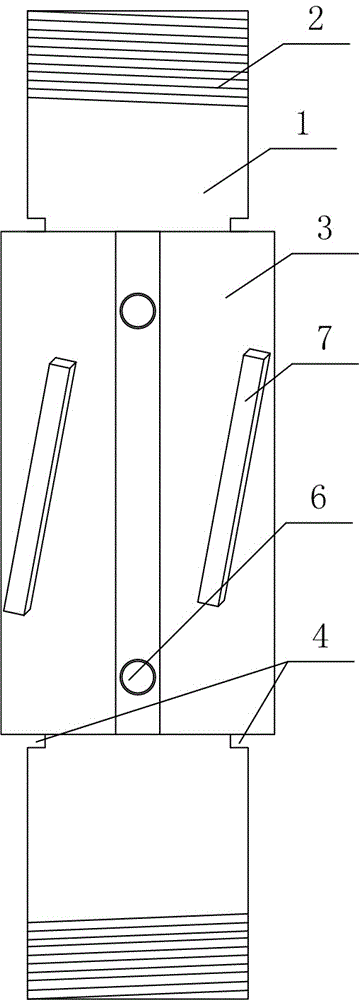

[0028] Threaded removable centralizers such as figure 1 and figure 2 As shown, it includes a core body 1, joints 2 arranged at both ends of the core body 1, a centralizer 3 sleeved on the core body 1, and the core body 1 is connected by a first core block 11 and a second core block 12 through threads constitute;

[0029] The core body 1 where the first core block 11 and the second core block 12 are threaded is provided with a groove 4 for the socket installation of the centralizer 3 , and the groove 4 is arranged along the outer circumference of the core body 1 .

[0030] The centralizer 3 is composed of a socket body 31 matching the shape of the groove 4 , and a centralizing block 32 fixedly arranged on the socket body 31 along the axial direction of the socket body 31 .

Embodiment 2

[0032] The difference between this embodiment and Embodiment 1 is that in this embodiment, the centering block 32 is provided with a through hole 5 with a circular cross section, and a ball 6 is installed in the through hole 5 .

[0033] The through hole 5 is composed of a large through hole arranged on the side wall of the centralizer 3 and used to place the ball 6, and a small through hole arranged on the surface of the centralizer 32 for preventing the ball 6 from coming out and exposing the ball on the surface of the centralizer 32. Composition; the small through hole communicates with the large through hole and is located on the same central axis.

[0034] The connection between the small through hole and the large through hole is arc-shaped.

[0035] Diagonal guide strips 7 are arranged between the righting blocks 32 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com