Quick Connect Angle Valve Assemblies

A quick connection, angle valve technology, applied in the direction of sleeve/socket connection, pipe/pipe joint/pipe fitting, passing element, etc., can solve the problems of inability to rotate and tighten, inconvenient installation of angle valve, and difficult winding of raw material tape, etc. Reduce installation difficulty, save installation cost, and simple installation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] Embodiments of the present invention are described in detail below in conjunction with accompanying drawings:

[0038] It should be noted that when an element is said to be "fixed" to another element, it may be directly fixed to the other element or may be fixed to the other element through an intermediate element. When an element is referred to as being "connected to" another element, it can be directly connected to the other element or connected to the other element through intervening elements.

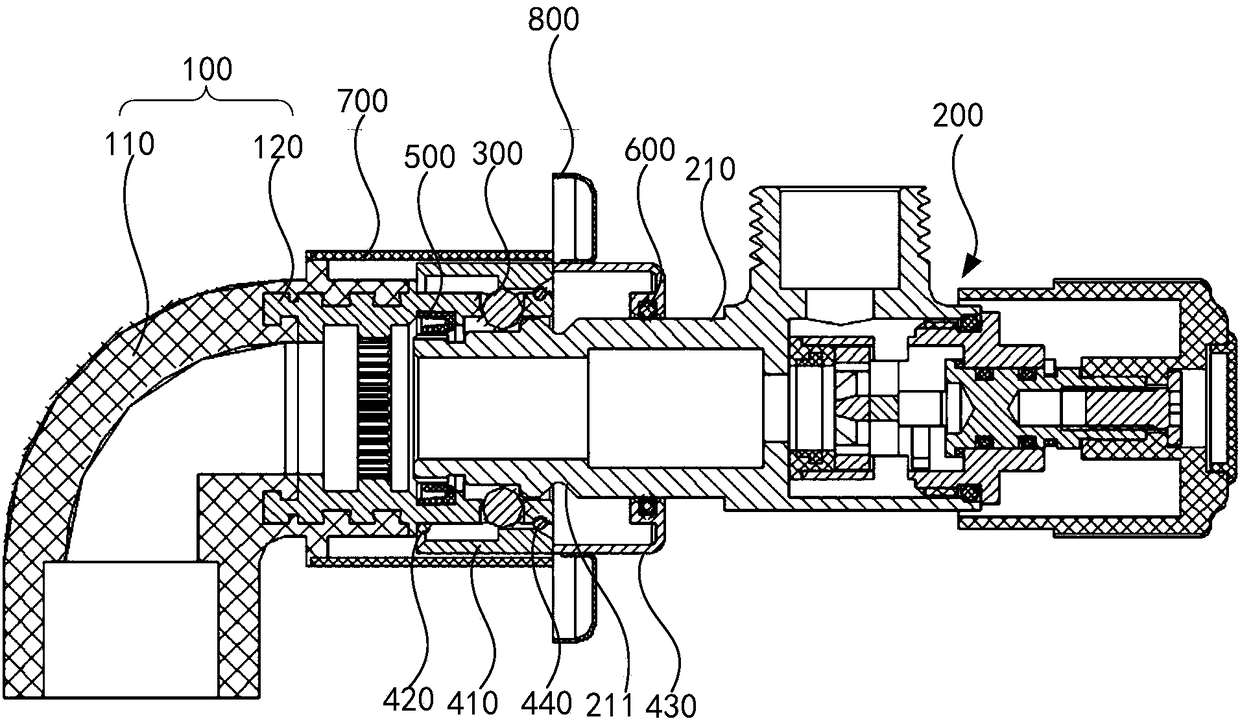

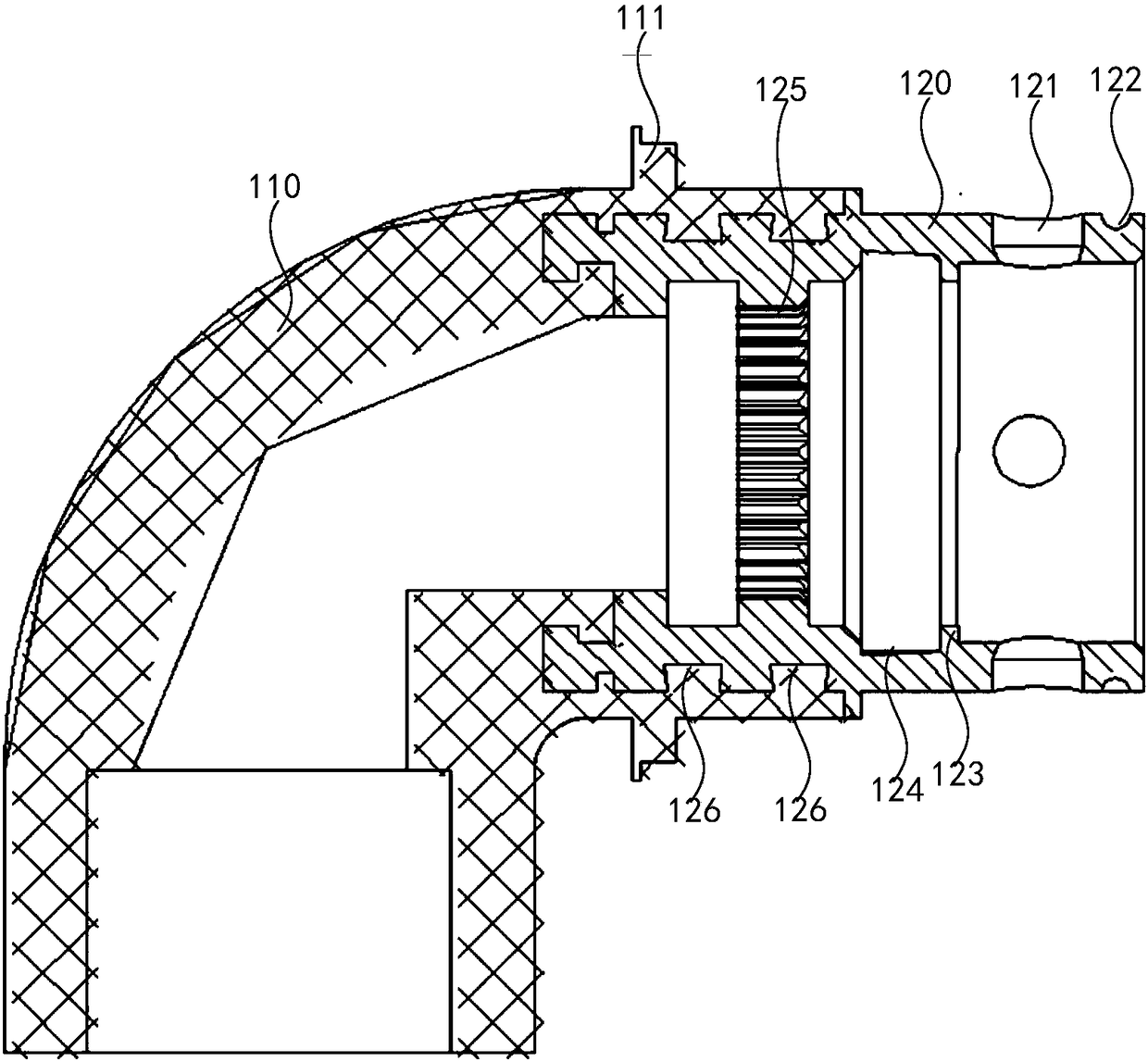

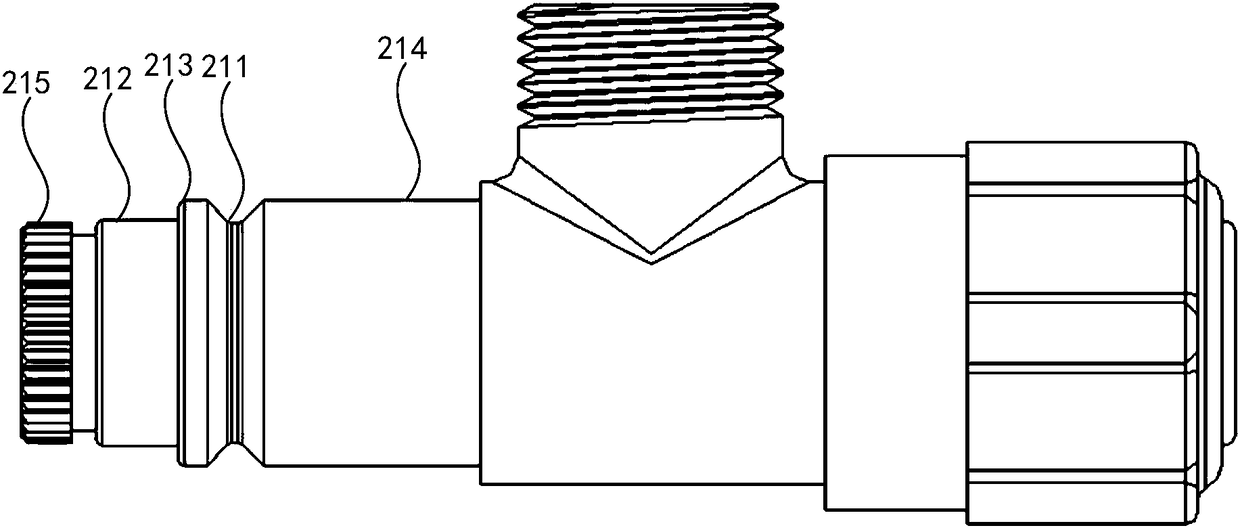

[0039] Such as Figure 1 to Figure 3As shown, a quick-connect angle valve assembly includes an outlet pipe 110, an inner sleeve 120, an angle valve 200 and a driving assembly. The water inlet joint 210 of the angle valve 200 is outside. The inner nest 120 is provided with a through hole 121 and is provided with a movable part 300 which is placed in the through hole 121 and can move back and forth along its radial direction. The movable part 300 fits into the slot 211 , an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com