Garbage gasification incinerator

A technology for incinerators and garbage, applied in the direction of incinerators, combustion methods, combustion types, etc., can solve the problems of low heat dissipation and building sheds, and achieve the effects of reducing adhesion, uniform distribution, and ensuring continuity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

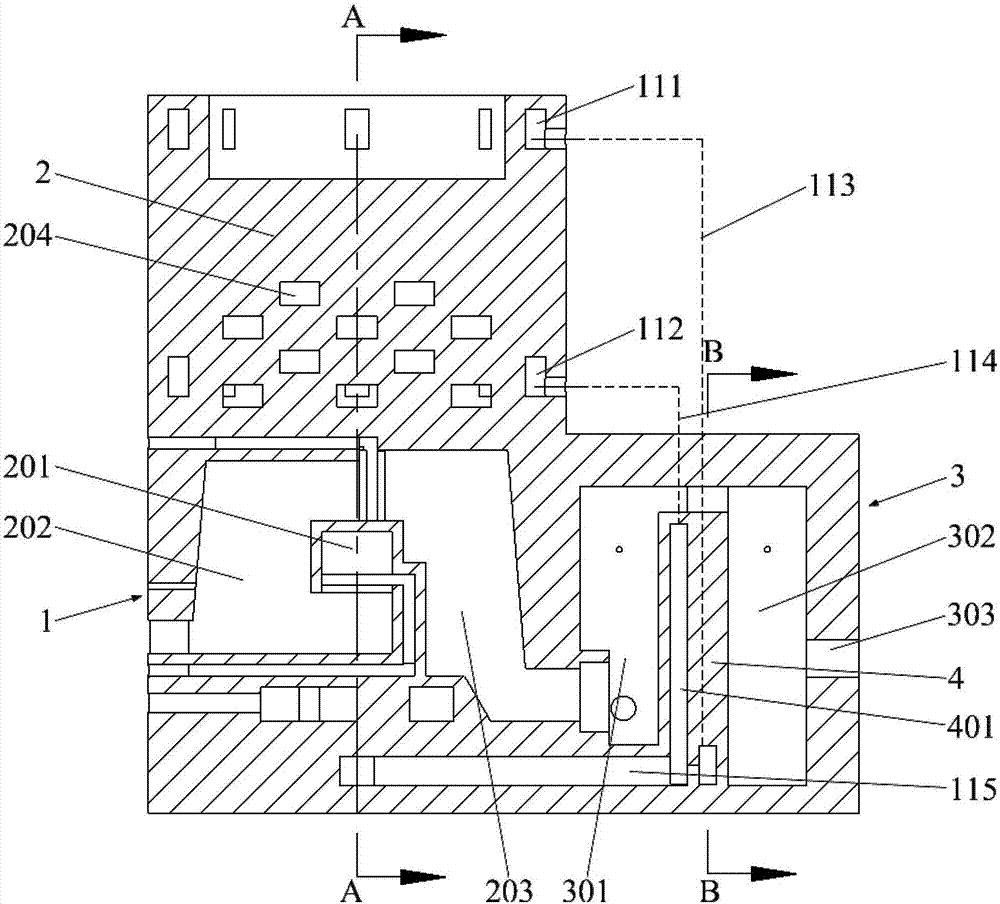

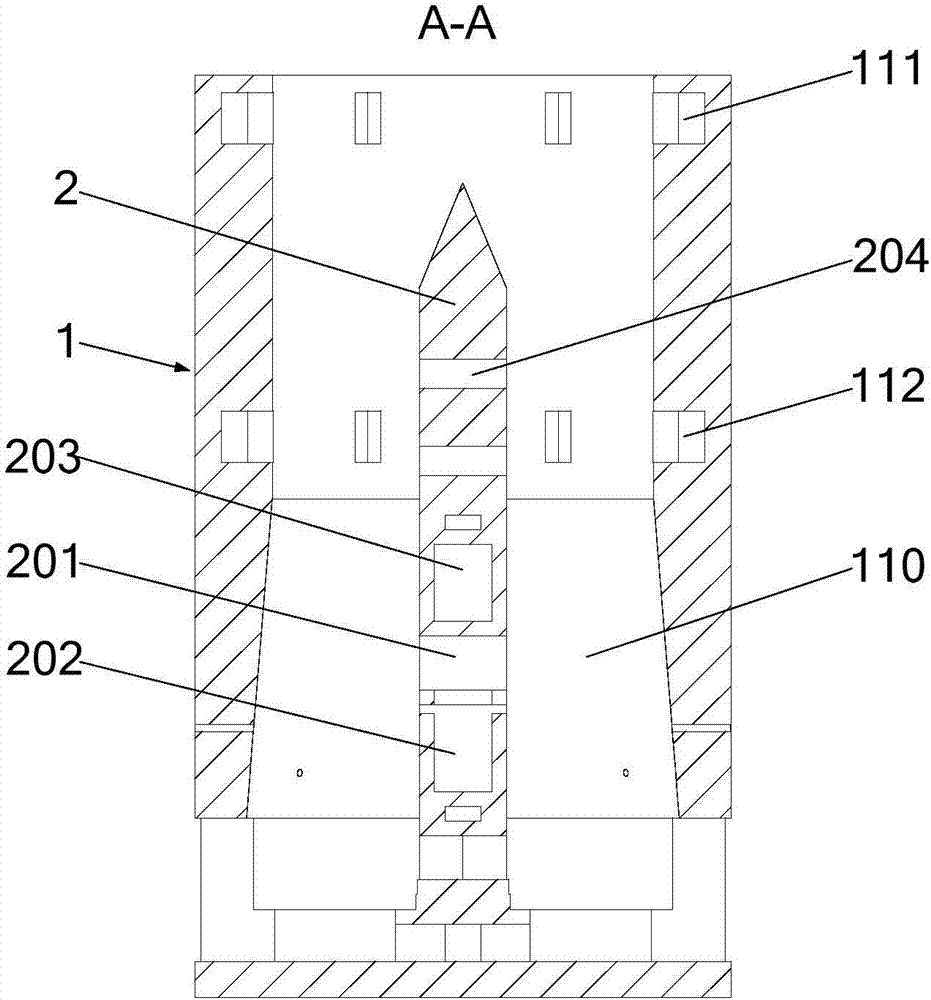

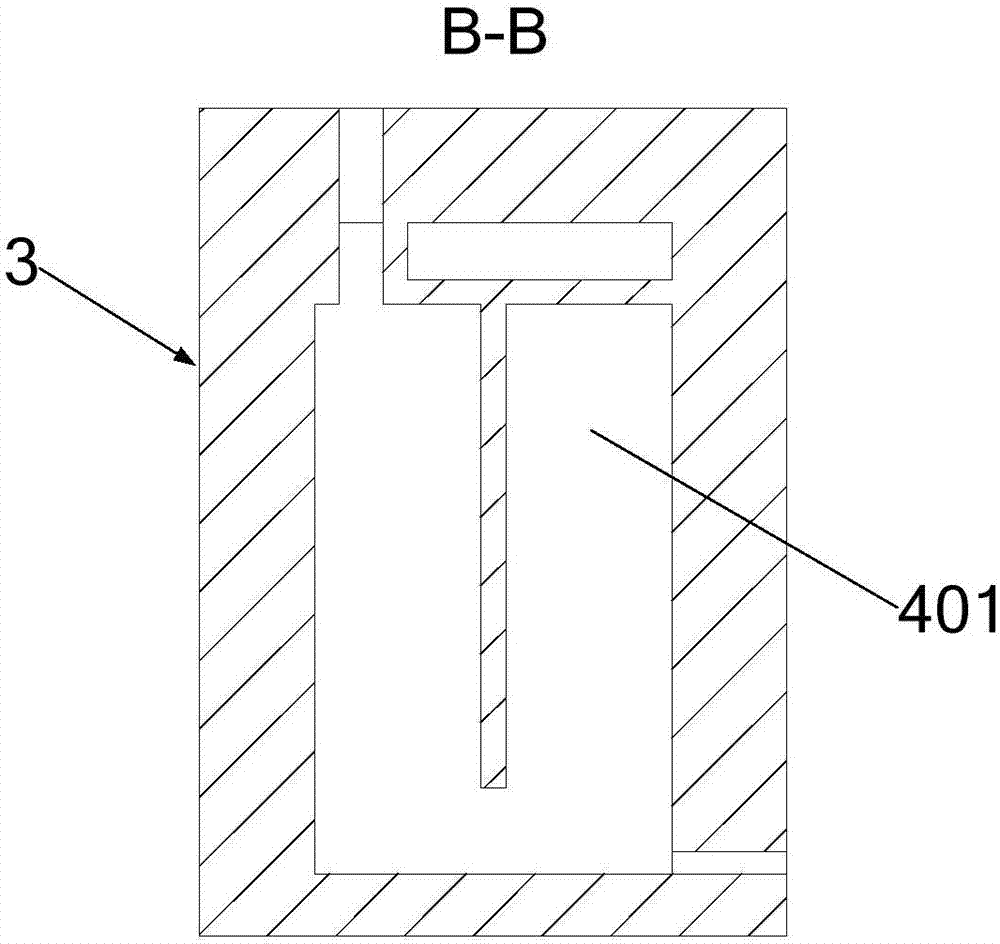

[0025] refer to figure 1 and 2 , an embodiment of the present invention provides a garbage gasification incinerator, including a main furnace body 1 and a partition wall 2, the furnace of the main furnace body 1 is a gasification combustion chamber 110, and the top of the gasification combustion chamber 110 is set There is a blanking opening; the partition wall 2 is vertically arranged in the gasification combustion chamber 110, the partition wall 2 is located directly below the blanking opening, and divides the gasification combustion chamber 110 into two Part, the partition wall 2 is provided with one or more flue gas combustion chambers connected in series in sequence, and the entrance of the flue gas combustion chamber or the first flue gas combustion chamber is connected with the gasification combustion chamber 110 connected.

[0026] In the above embodiments, the partition wall 2 is located directly below the discharge port, and divides the gasification combustion cham...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com