Method for detecting wearing property of vulcanized rubber under damp and hot conditions

A vulcanized rubber, moist heat technology, applied in the direction of testing wear resistance, measuring device, strength characteristics, etc., can solve the problems of not publicly testing the rubber wear performance, the use effect is very different, meeting the service life requirements, etc., to optimize the anti-humid heat wear performance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

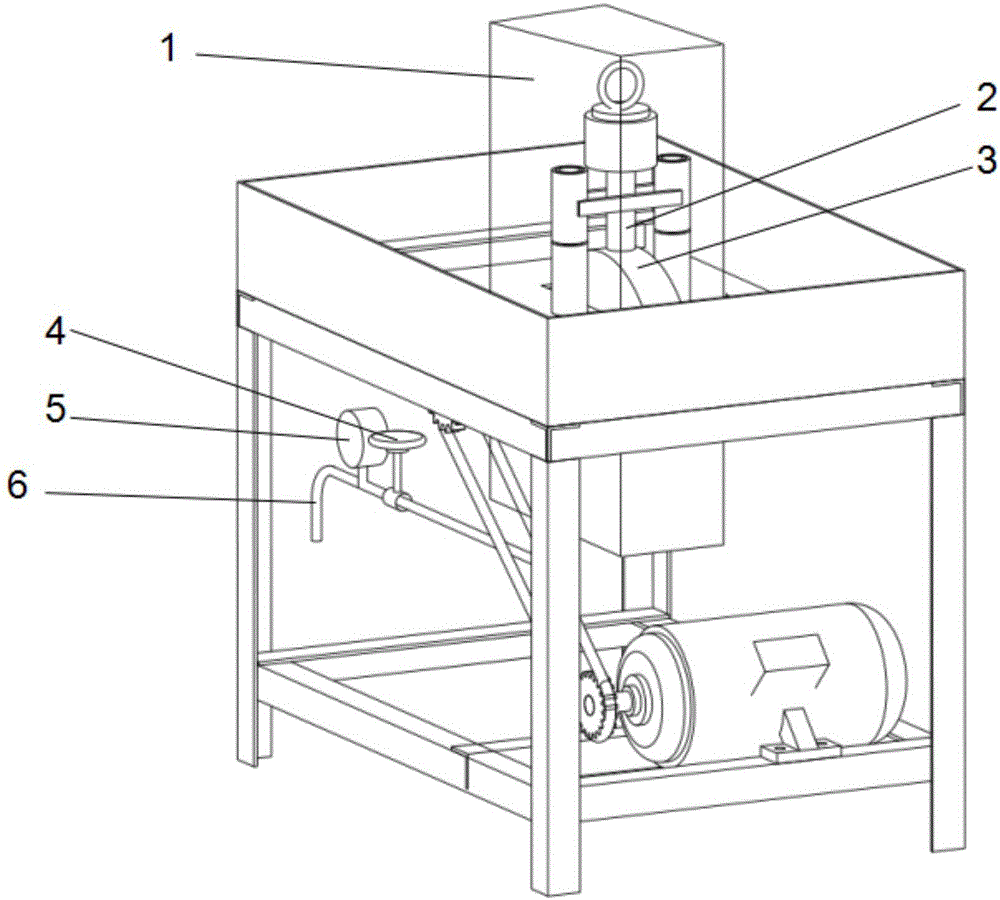

[0033] The equipment used as the method of the present invention can be found in figure 1 . figure 1 The middle sealed space is a space surrounded by a cuboid shell, which contains the sample and the grinding wheel, and the external water vapor is introduced into it through the pipe. Valves and pressure gauges are installed on the pipeline to control the water vapor pressure and temperature in the sealed space. In this embodiment, the pipeline is arranged at the bottom of the enclosure in the sealed space. This arrangement allows the pipes to be used both for introducing water vapor during wear and for draining water from the bottom of the sealed space when wear is over.

Embodiment 2

[0035] Conditions and steps of the method of the present invention can be as follows:

[0036] 1. The ventilation effect of the laboratory and the drainage pipe are better;

[0037] 2. The laboratory temperature is 23±2℃;

[0038] 3. Before the hot and humid friction of the sample, the steam at the test temperature must be introduced into the sealed space for 5 minutes to reach the test temperature;

[0039] 4. During the friction test of the sample, the steam pressure must be kept within ±3°C of the required temperature;

[0040] 5. Carefully observe the wear of the sample during the test to prevent the sample groove from being worn out;

[0041] 6. In order to speed up the display of experimental results, it can be increased by 50%-100% according to the rated gravity;

[0042] 7. The sample should be in a dry state before and after the experiment, and weighed on a 1 / 10000 electronic balance;

[0043] 8. Determine the amount of wear according to the specific gravity and w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com