A kind of grouting process of ceramic green body

A ceramic body and process technology, applied in the field of ceramic manufacturing, can solve the problems of long high-pressure grouting time, low production efficiency, insufficient pressure, etc., achieve the effects of reducing production cycle, avoiding quality defects, and reducing production cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] In order to make the technical problems, technical solutions and beneficial effects to be solved by the present invention clearer and clearer, the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

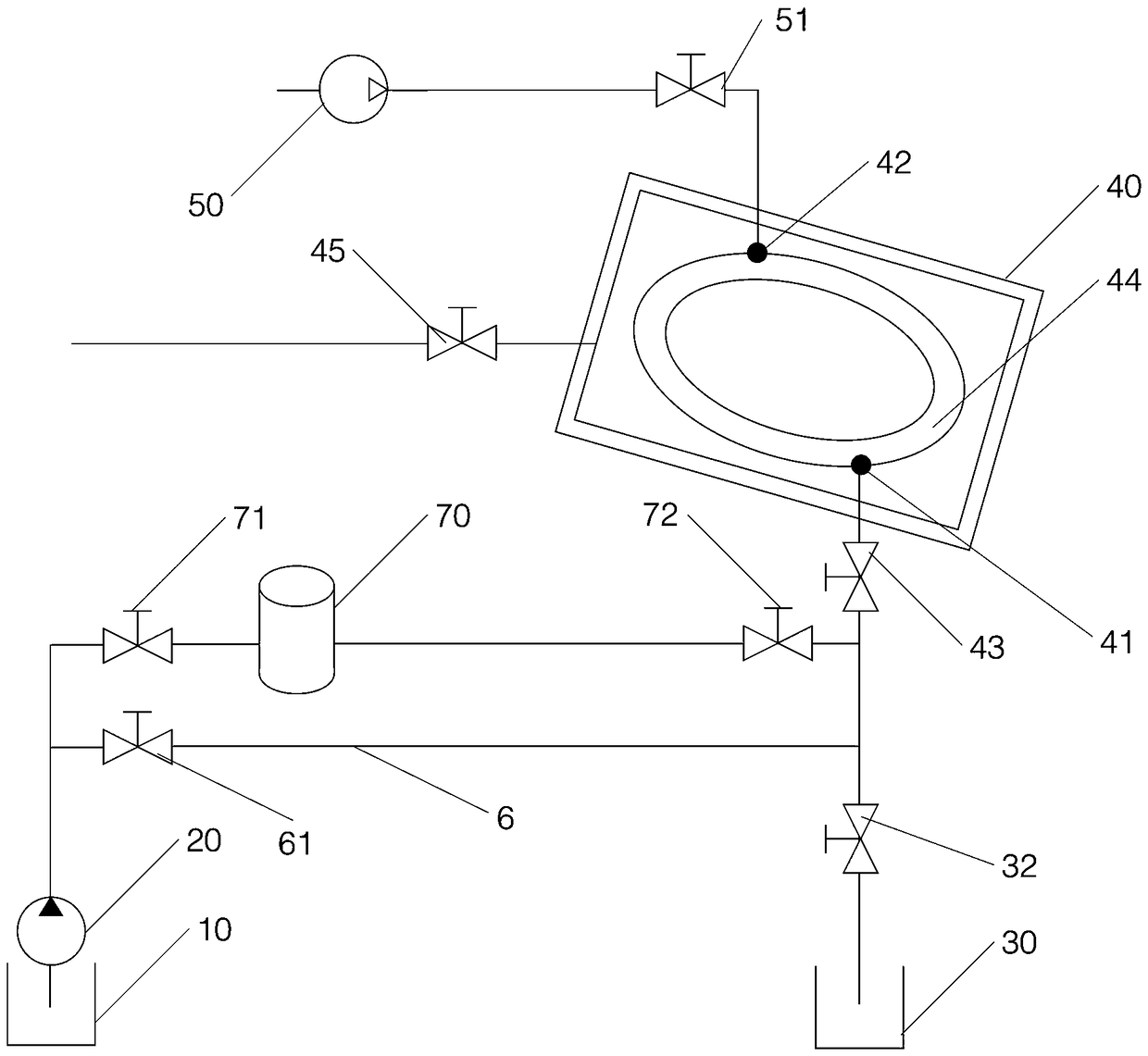

[0030] like figure 1 Shown, technical scheme in the present invention can be realized in the following manner:

[0031] The mud pump 20 is connected to the mud tank 10, and pumps the mud in the mud tank 10 into required pipelines.

[0032] Out-of-mold drainage and exhaust valve 45 communicates with the water hole of the mold to discharge the air and water absorbed by the inner wall of the mold from the mold.

[0033] Step 0.1: In the high-pressure tank circulation step, the mud pump 20 can be controlled to connect the high-pressure mud tank 70 and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com