Method for calculating crimping resistance at joint of middle connector of high-voltage single-core cable

A single-core cable and intermediate joint technology, applied in the field of crimping resistance, can solve the problems of lack of detection means and calculation methods, and achieve the effect of efficient detection means, simple calculation method and simple measurement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The present invention will be further explained below in conjunction with specific embodiments.

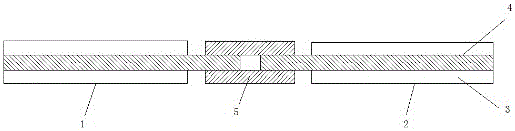

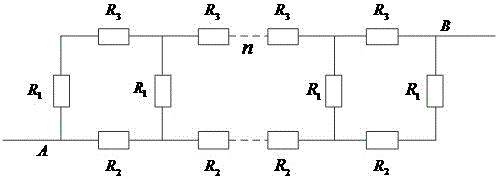

[0037] refer to Figure 1-2 , the calculation method of the crimping resistance of a kind of high-voltage single-core cable intermediate joint connection that the present invention proposes, comprises the following steps:

[0038] S1, using a measuring tool to measure the size of the connecting pipe 5;

[0039] S2, determining the crimping length and crimping force parameters of the high-voltage single-core cable intermediate joint connection;

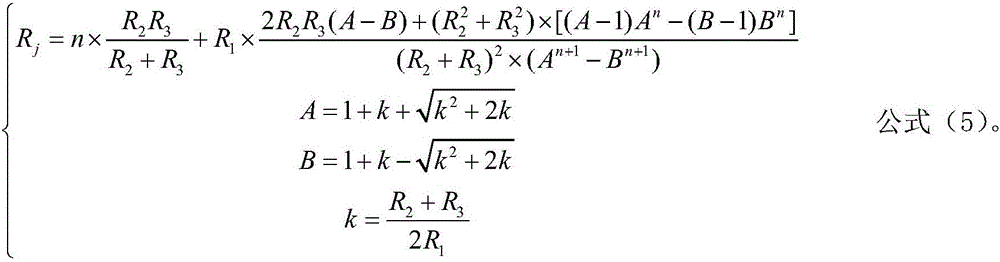

[0040] S3, calculating the total contact resistance of the contact surface between the connecting pipe 5 and the cable core 4;

[0041] S4, calculating the body resistance of the connecting pipe 5 at the connection portion where the connecting pipe 5 is not in contact with the cable core 4;

[0042] S5, calculate the total crimping resistance at the connection.

[0043] The outer sides of the first cable 1 and the second cable 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com