Distribution equipment inspection tour system and method

A technology of power distribution equipment and inspection system, applied in the direction of information technology support system, electrical components, circuit devices, etc., can solve the problems of human resource occupation, failure to eliminate faults in time, scattered monitoring nodes, etc., to improve accuracy and Timeliness, avoiding untimely rush repairs, and reducing labor costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

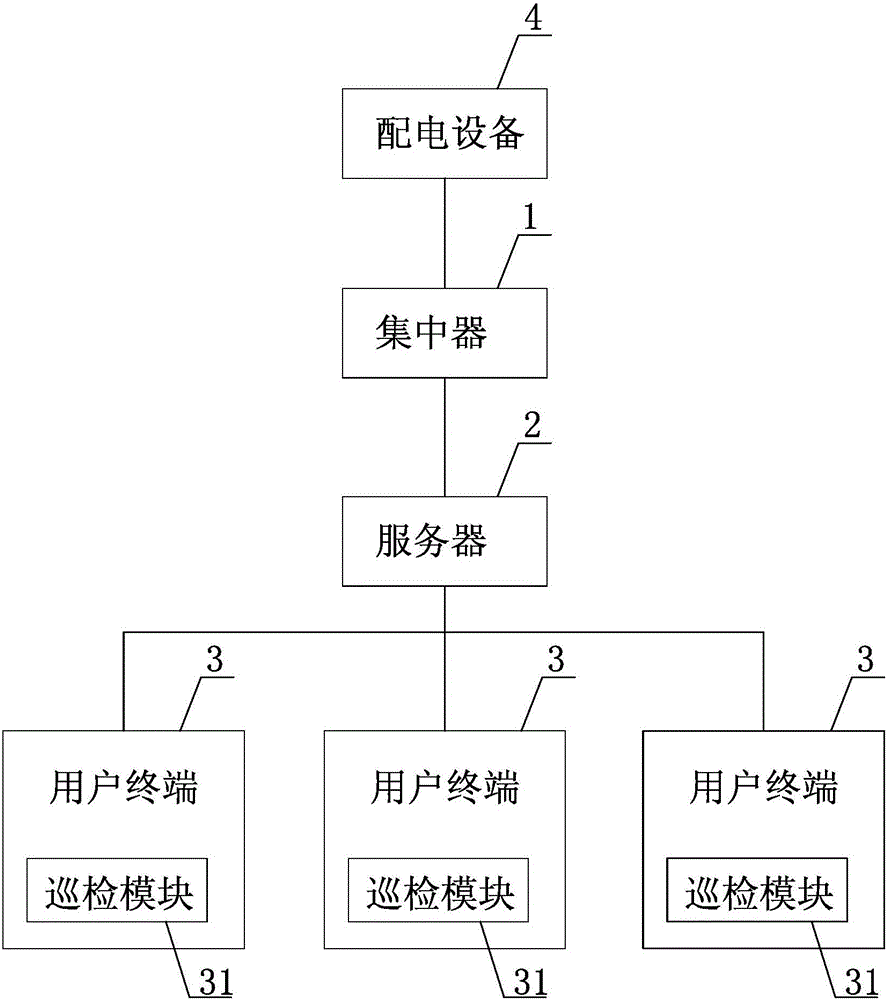

[0026] Such as figure 1 As shown, the power distribution inspection system includes a concentrator 1, a server 2 and three user terminals 3. The concentrator 1 communicates with the power distribution equipment 4 through RS485 or Ethernet, and communicates with the server 2 through a wireless network. Multiple users The terminal 3 can perform data communication with the server 2 through the wireless network. The user terminal 3 has an inspection module 31. The inspection module 31 divides the power distribution area into multiple inspection areas according to the power supply area of the transformer. Each inspection area is associated with three inspection personnel, and the inspection personnel log in to the inspection module through authorization. 31 to correlate to the corresponding inspection area, the inspection personnel with higher authority can assign the association relationship between the inspection personnel with low authority and the inspection area, and upload ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com