Power supply module with cofferdam

A technology of power modules and cofferdams, which is applied in the direction of electrical components, electrical equipment structural parts, cooling/ventilation/heating transformation, etc. It can solve the problems of affecting the service life and the inability of power modules to dissipate heat, so as to prolong the service life and increase heat conduction Excellent function and cooling efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The principle and structure of the present invention will be described in detail below in conjunction with the accompanying drawings.

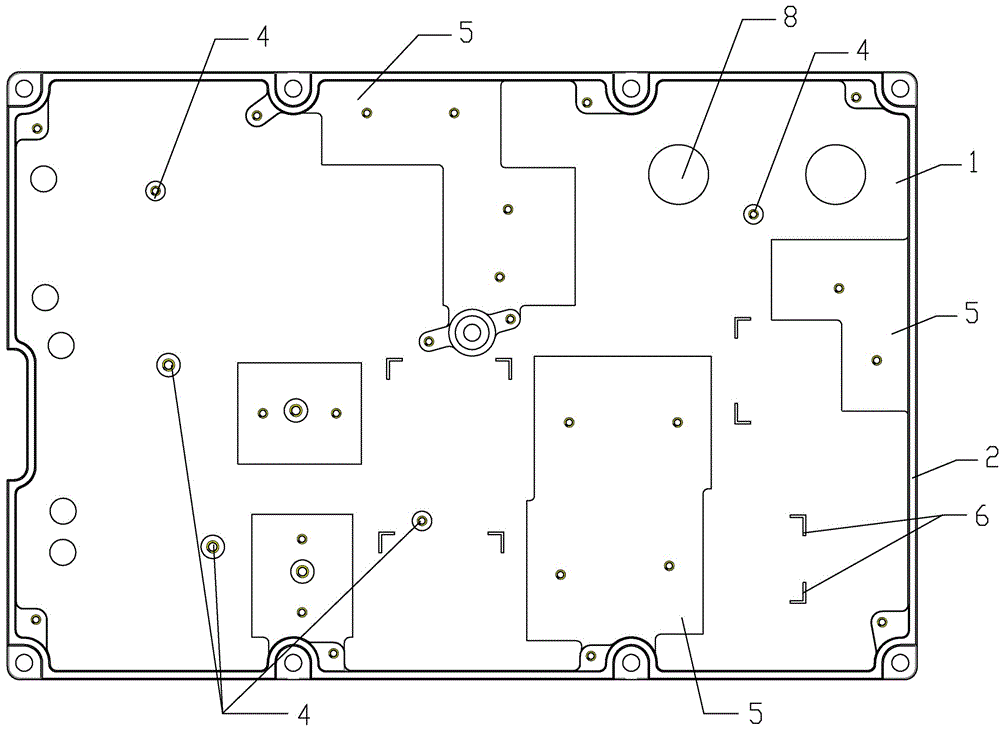

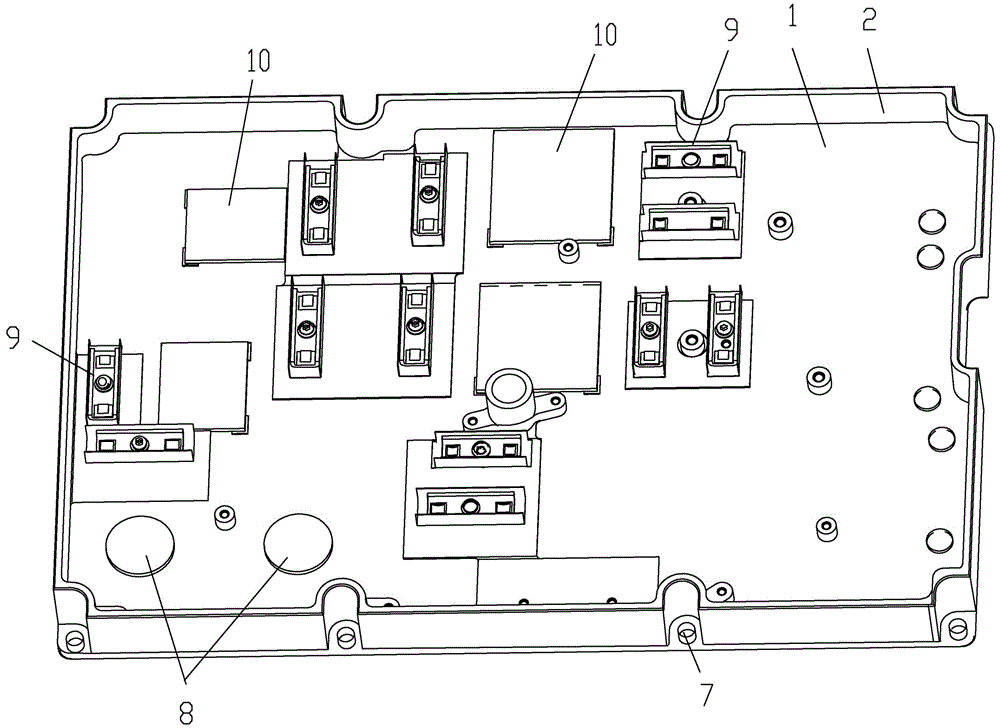

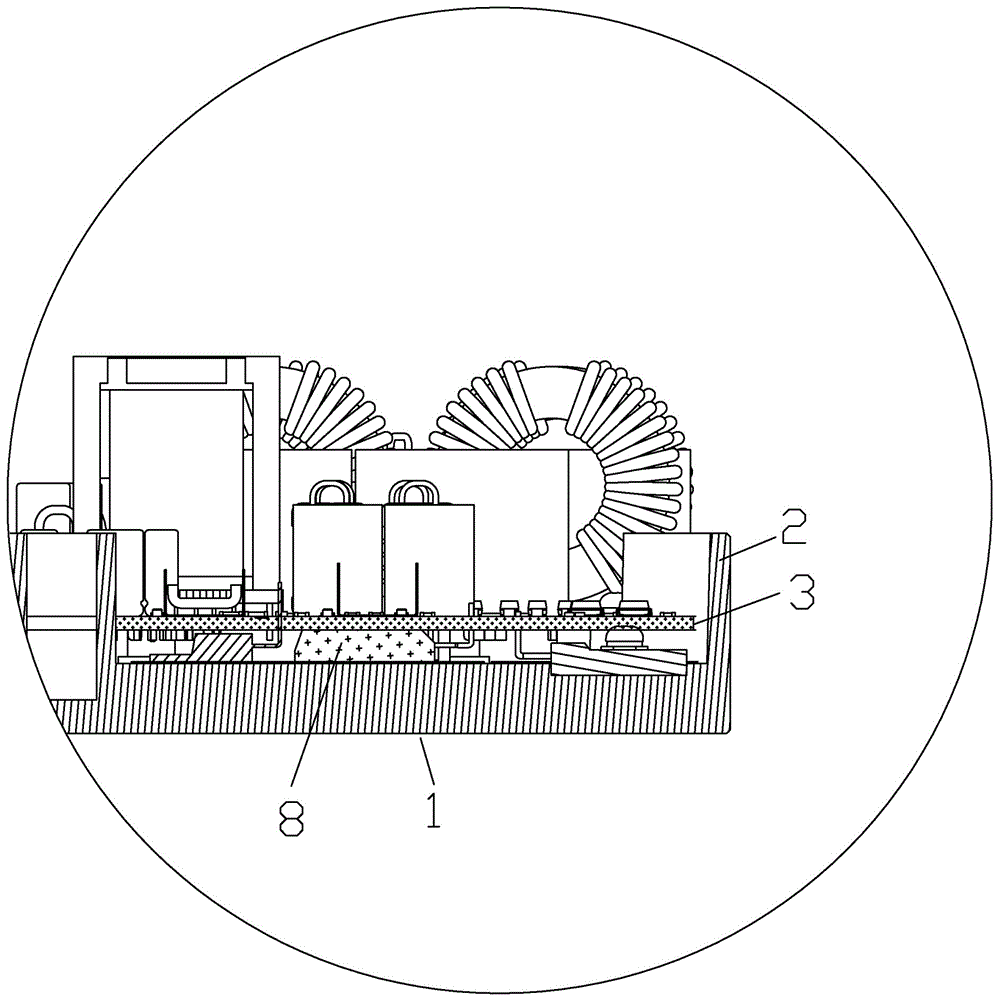

[0014] Such as Figure 1 to Figure 4 As shown, the power supply module with a cofferdam provided by an embodiment of the present invention is an open power supply module, and its specific structure includes a bottom plate 1 surrounded by a cofferdam 2 that surrounds the bottom plate 1 into a closed environment. , can be used to fill thermal paste.

[0015] According to the requirements of safety regulations, the distance between the conductive metal and component pins on the circuit board 3 and the casing is more than 2.0mm, so there are multiple support columns 4 with screw holes on the bottom plate, and the circuit board 3 can be fixed on the On the supporting pillars 4, in addition to positioning the height of the circuit board 3, these supporting pillars 4 can also locate the distance between the board edge of the circuit board 3 a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com