A kind of loaded palladium multilayer composite film and preparation method thereof

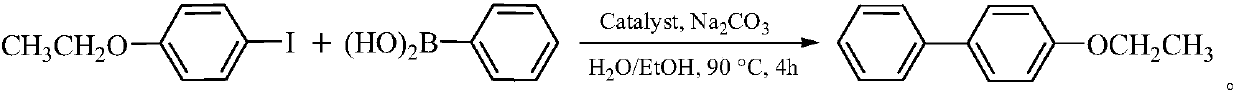

A multi-layer composite and thin-film technology, which is used in the preparation of organic compounds, chemical instruments and methods, and condensation between hydrocarbons and non-hydrocarbons to produce hydrocarbons, etc., can solve the problems of low catalyst service life, difficult recycling, and high reaction temperature. Achieve stable performance, high catalytic activity, and strong electron delocalization.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

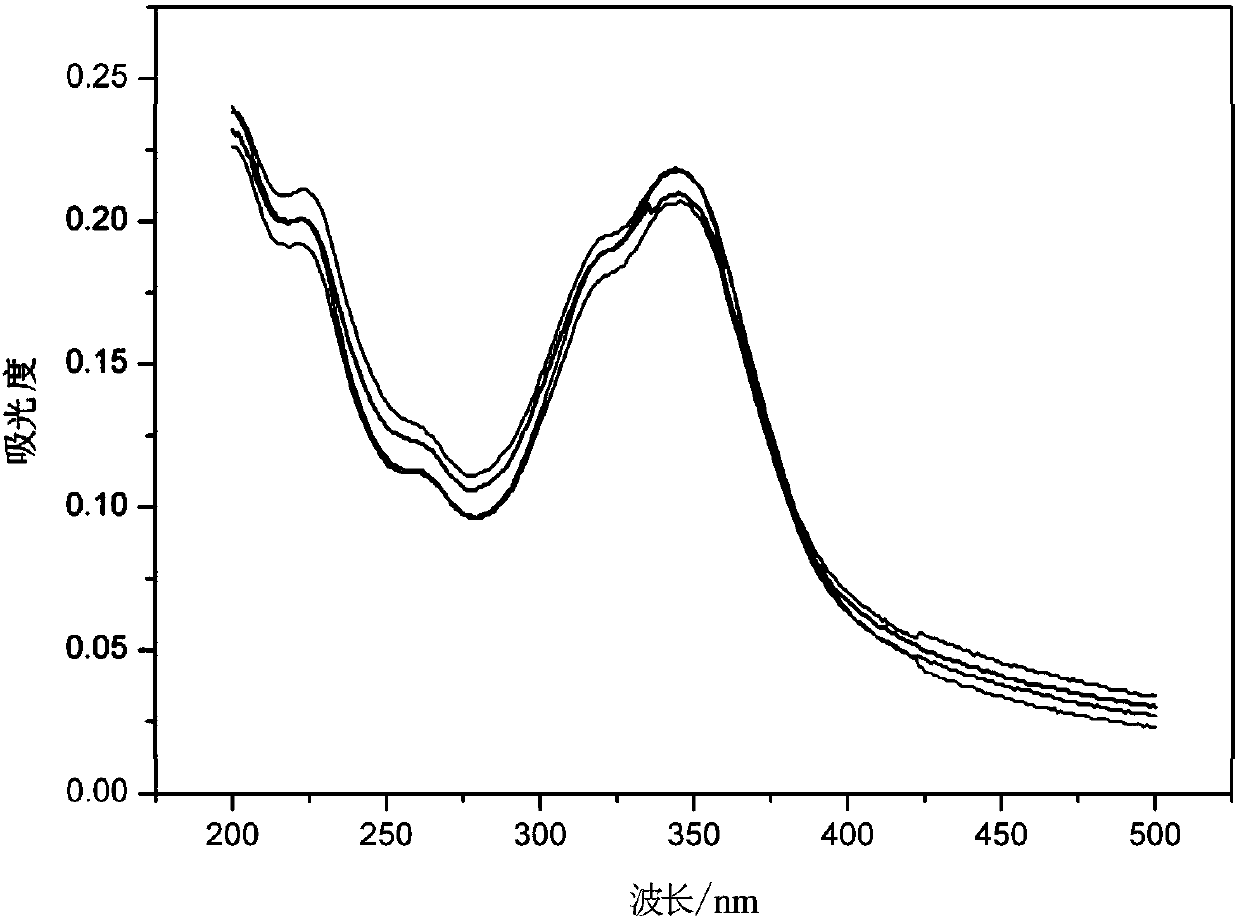

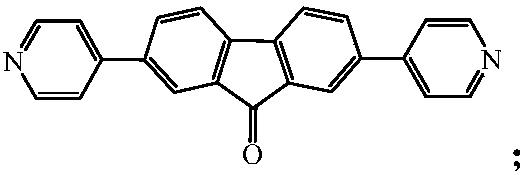

Embodiment 1

[0026] (1) Spray a layer of polyimide organic polymer film coating on the surface of a clean single crystal silicon wafer with a high-pressure vacuum gun, and then dry it with nitrogen flow; (2) apply polyimide organic polymer film The coated monocrystalline silicon chip is soaked in palladium acetate aqueous solution (concentration of palladium ion is 0.05mmol / L), takes out after 25min, cleans the free palladium ion on the surface with distilled water, blows dry with nitrogen flow afterwards, and then this monocrystalline Soak the crystalline silicon wafer in an acetone solution of fluorenonepyridine (0.05mmol / L) for 25min, take it out, rinse it with distilled water and blow it dry with nitrogen flow, and form a composite film of palladium fluorenonepyridine loaded on the surface of the single crystal silicon wafer; (3) in step (2), on the monocrystalline silicon chip that one deck palladium fluorenone pyridine composite film is formed on the surface, spray one deck polyimide ...

Embodiment 2

[0028] (1) spray one layer of polystyrene organic polymer film coating on the clean mica sheet surface with a high-pressure vacuum gun, then blow dry with nitrogen flow; (2) will be coated with polystyrene organic polymer film coating Soak the mica sheet in an aqueous solution of palladium nitrate (the concentration of palladium ions is 0.1mmol / L), take it out after 45 minutes, wash the free palladium ions on the surface with distilled water, and then dry it with a nitrogen stream, and then place the mica sheet in the fluorenone pyridine Soak in the acetone solution (concentration of fluorenone pyridine is 0.1mmol / L) for 45min, take out and rinse with distilled water and blow dry with nitrogen flow, promptly form the composite thin film of one deck loading palladium fluorenone pyridine on the mica sheet surface; (3) In step (2), on the mica sheet that one deck palladium fluorenone pyridine composite film is formed on the surface, spray one deck polystyrene organic polymer film ...

Embodiment 3

[0030] (1) Spray a layer of polyimide organic polymer film coating on the surface of a clean quartz sheet with a high-pressure vacuum gun, and then dry it with nitrogen flow; (2) coat the polyimide organic polymer film The quartz sheet of layer is soaked in palladium nitrate aqueous solution (concentration of palladium ion is 0.08mmol / L), takes out after 30min, cleans the free palladium ion on the surface with distilled water, blows dry with nitrogen flow afterwards, and then this quartz sheet is placed in fluorene Soak in the acetone solution of ketopyridine (the concentration of fluorenone pyridine is 0.07mmol / L), take out and rinse with distilled water and blow dry with nitrogen flow, promptly form the composite thin film of one deck loading palladium fluorenone pyridine on the quartz plate surface; 3) In the step (2), the surface forms a layer of loaded palladium fluorenone pyridine composite film on the quartz sheet, and then sprays a layer of polyimide organic polymer fil...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com