A Spraying Protection Process for Girth Welding Welding Seam of Stainless Steel Water Tank Liner

A technology of stainless steel and girth welding, applied in coatings, welding equipment, manufacturing tools, etc., can solve problems such as corrosion and leakage, and achieve the effect of eliminating corrosion and water leakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The invention discloses a process for spraying and protecting weld seams of stainless steel water tank liner girth welding, which includes the following steps:

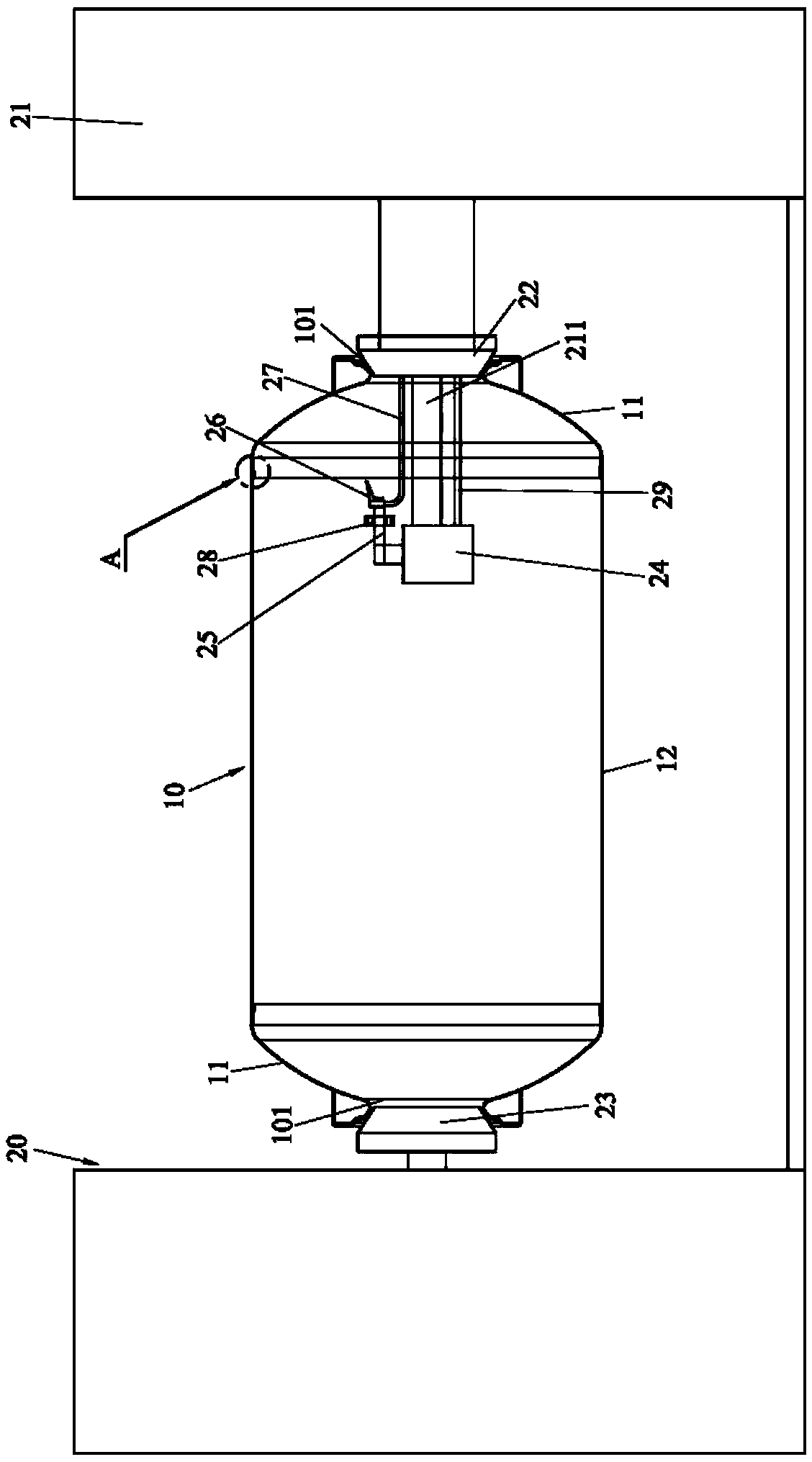

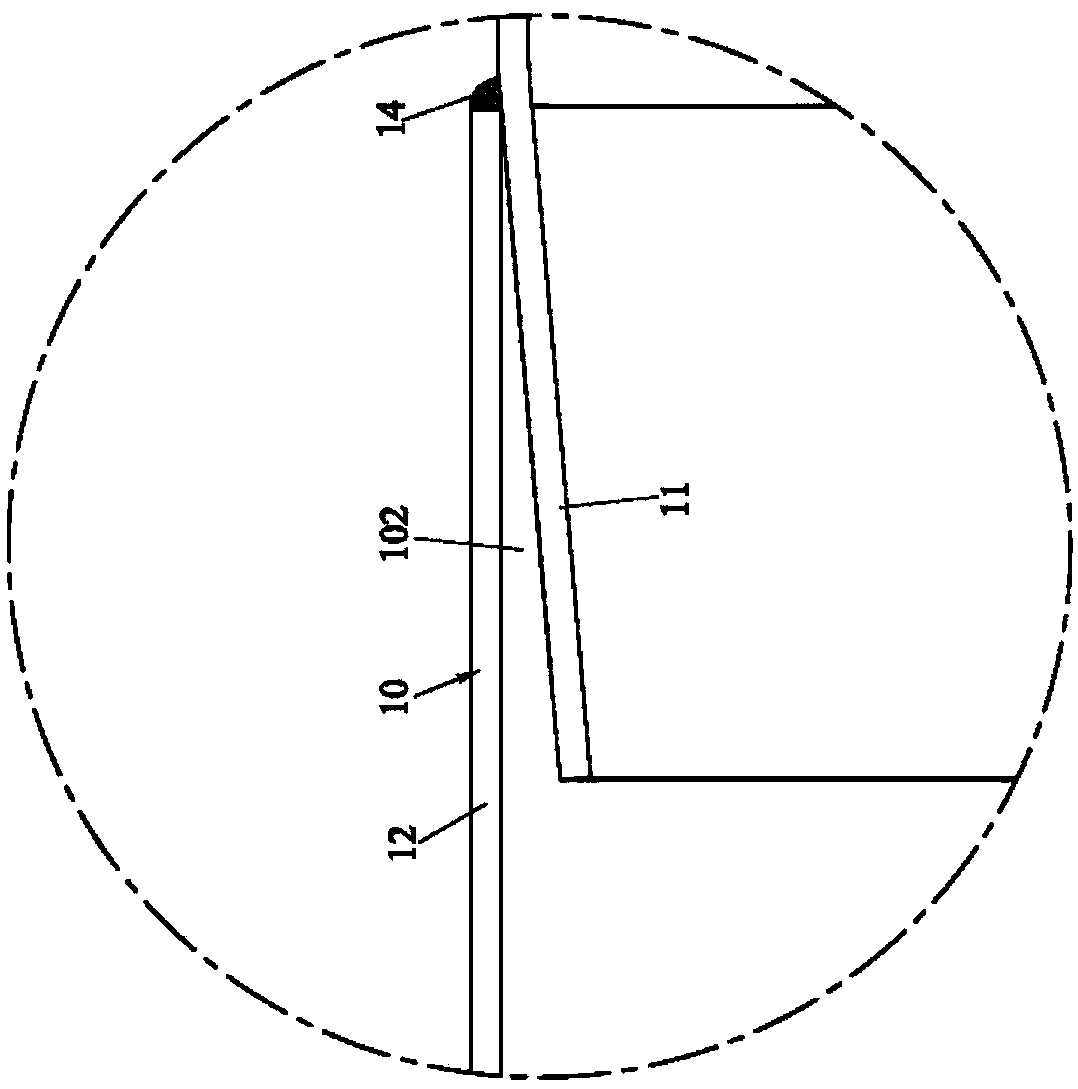

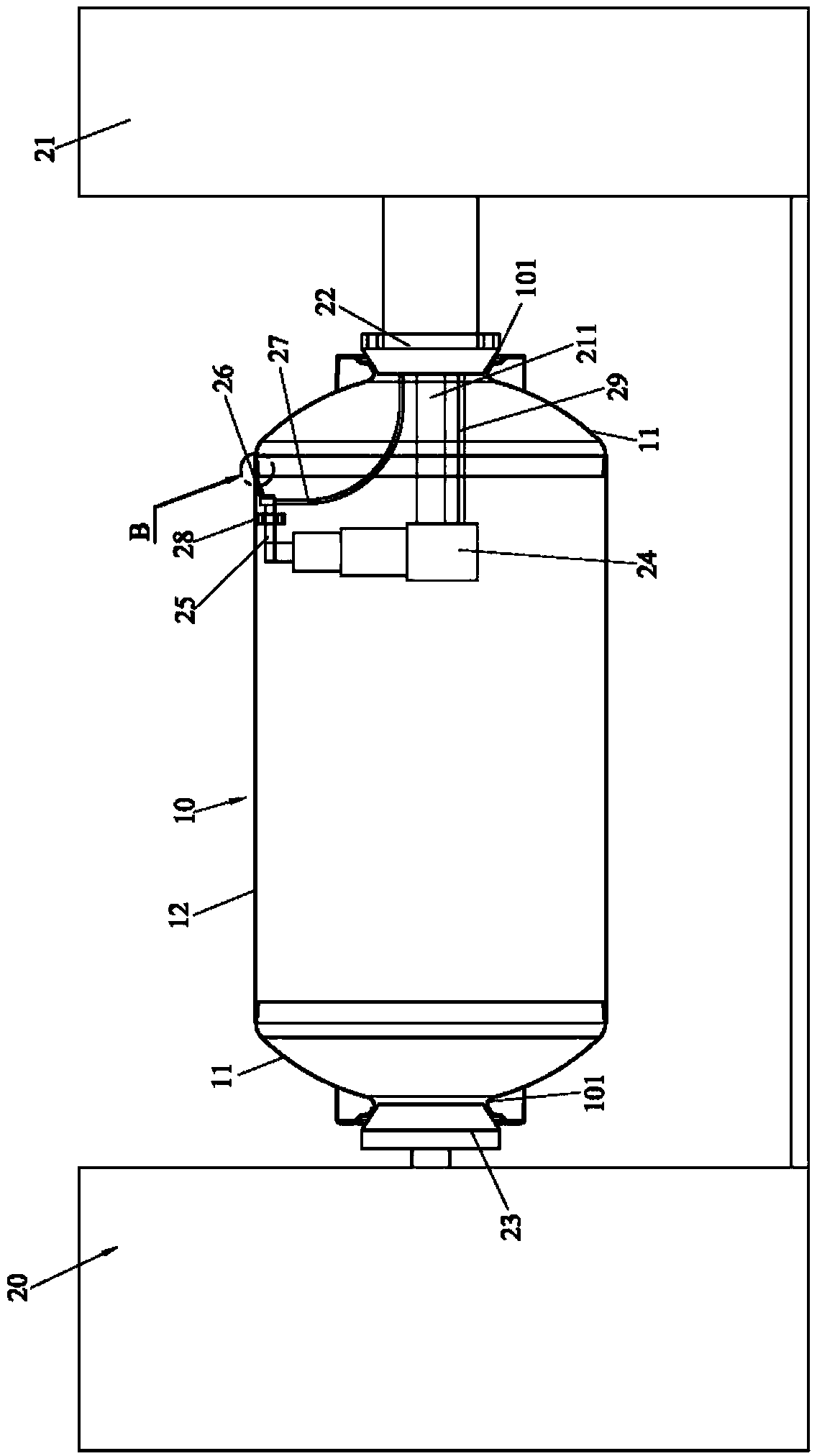

[0029] (1) Put the inner tank 10 of the welded head 11 into the auxiliary equipment 20, which includes a support 21, a driven turntable 22, a driving turntable 23, a driving mechanism 24, a movable part 25 and a nozzle 26, the support 21 has a fixed rod 211 for extending into the inner container 10, the driven turntable 22 and the driving turntable 23 face each other, the driving turntable 23 is driven to rotate by a motor (not shown in the figure), and the driving mechanism 24 is arranged on the fixed rod At the outer end of 211, the movable part 25 is arranged on the driving mechanism 24, and the driving mechanism 24 drives the movable part 25 to move along the radial direction of the liner 10. The nozzle 26 is fixed on the movable part 25, and the nozzle 26 is connected with a high-pressure rubber delivery pi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com