A Coating Machine Front and Back Coating Alignment System

A front and back, coating machine technology, applied in the field of coating machines, can solve the problems of finished product scrapping, achieve the effect of strong anti-drying ability, avoid work delay and waste, and meet the requirements of finished product yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

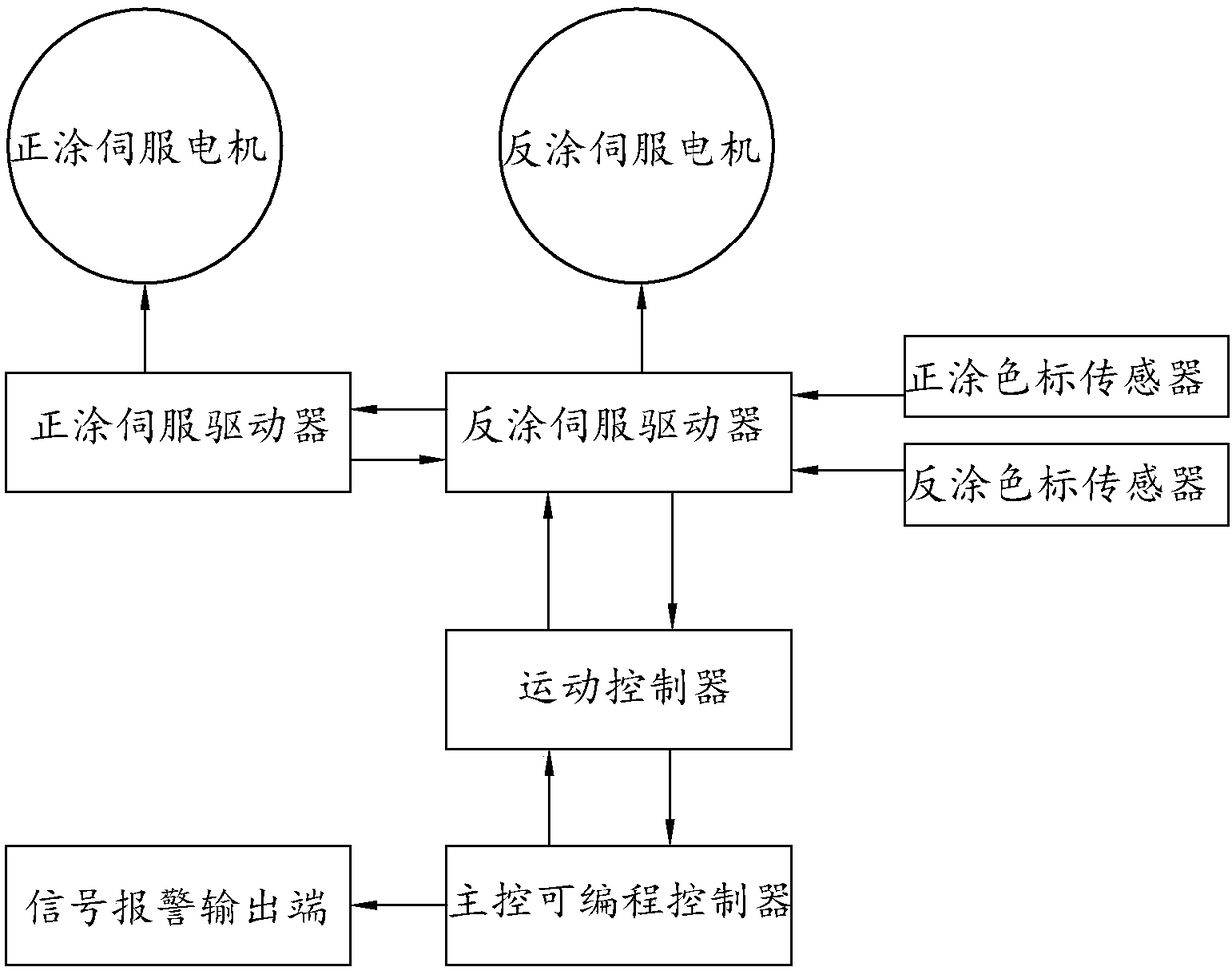

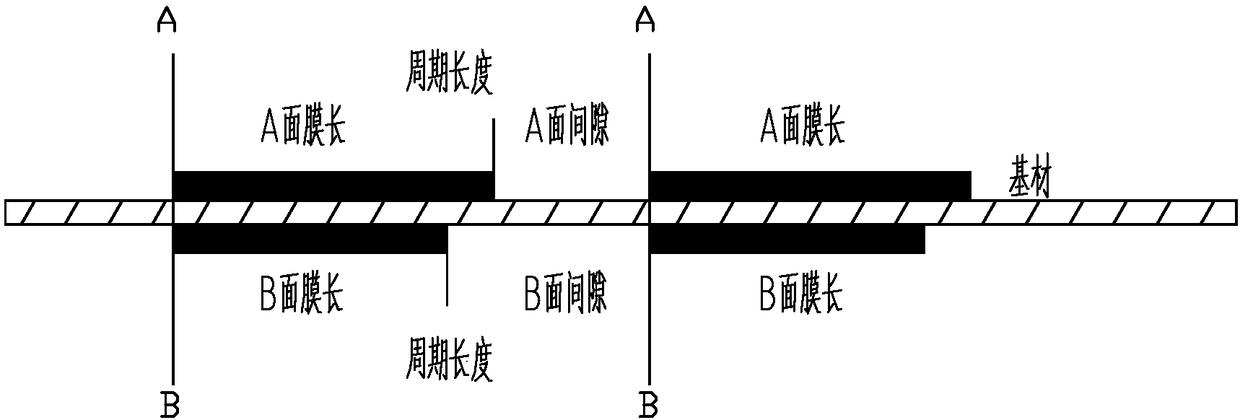

[0015] like Figure 1-Figure 2 As shown, it is a front and back coating alignment system of a coating machine of the present invention, including: a main control programmable controller, a motion controller, a front coating servo driver, a reverse coating servo driver, a front coating servo motor, a reverse coating A servo motor, a positive coating color mark sensor and a reverse coating color mark sensor; the positive coating servo motor and the reverse coating servo motor are respectively provided with encoders at their shaft ends;

[0016] Wherein, the motion controller, the front coating servo driver, and the reverse coating servo driver are connected by a bus, and the front coating servo driver is connected to the motion controller through the reverse coating servo driver; the front coating color mark sensor and the reverse coating color mark sensor are both The reverse coating servo driver and the motion controller are respectively connected to the main control programma...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com