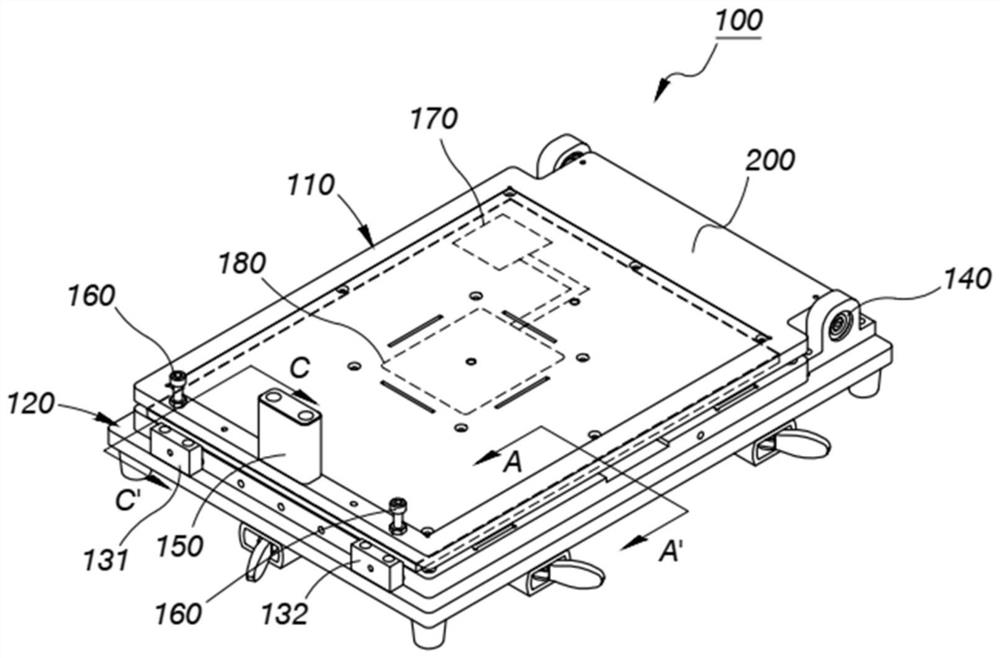

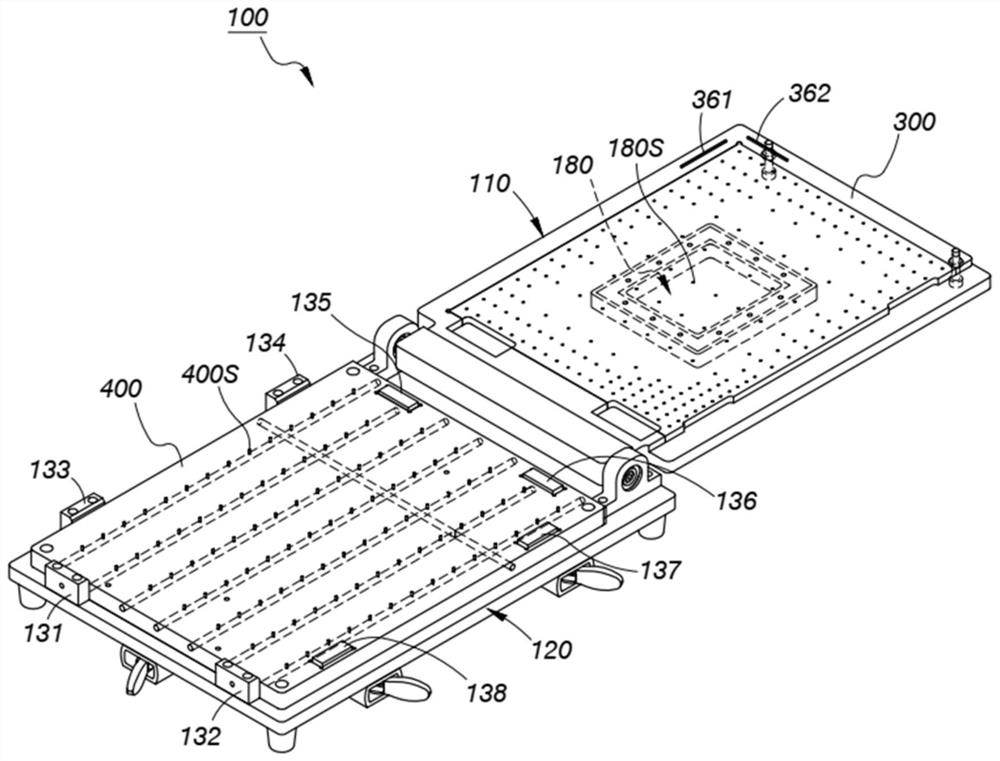

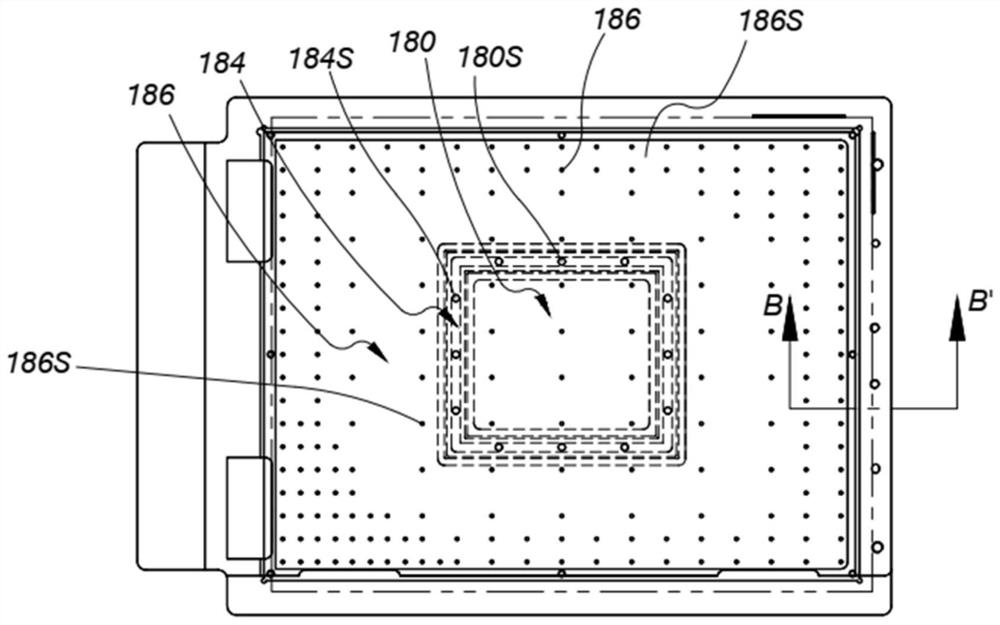

Film sticking device and its jig

A film sticking device and fixture technology, applied in packaging and other directions, can solve problems such as product damage, failure to provide yield, product crushing or crushing, etc., achieve good scratch protection, improve film sticking efficiency and quality, and reduce man-made problems The effect of mistakes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0056] The disclosure is particularly described with the following examples, which are for illustration only, since various changes and modifications may be made by those skilled in the art without departing from the spirit and scope of the disclosure, therefore The scope of protection of this disclosure should be defined by the scope of the appended patent application. Throughout the specification and claims, the meanings of "a" and "the" include that such description includes "one or at least one" of the element or component, unless the content clearly specifies otherwise. Furthermore, as used in this disclosure, a singular article also includes the description of plural elements or ingredients unless it is obvious from the specific context that the plural is excluded. Also, as applied in this description and all claims below, the meaning of "in" may include "in" and "on" unless the content clearly dictates otherwise. The terms (terms) used throughout the specification and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com