Drawing method and drawing mould for U-shaped drawn component

A drawing die and U-shaped technology, which is applied in the field of mechanical processing, can solve problems such as wrinkling and poor flatness of U-shaped stretched parts, and achieve the effects of simple structure, improvement of poor flatness and wrinkling, and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

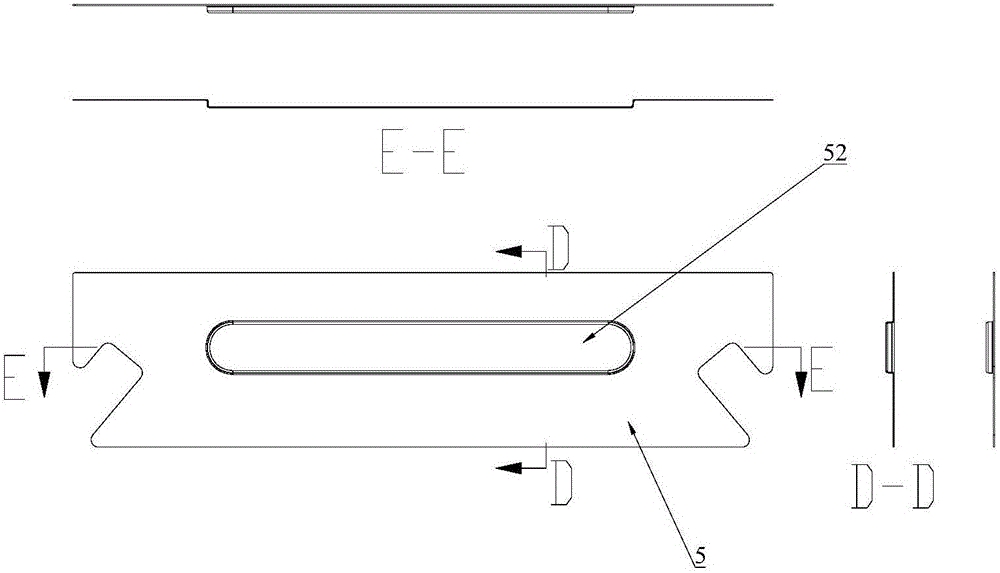

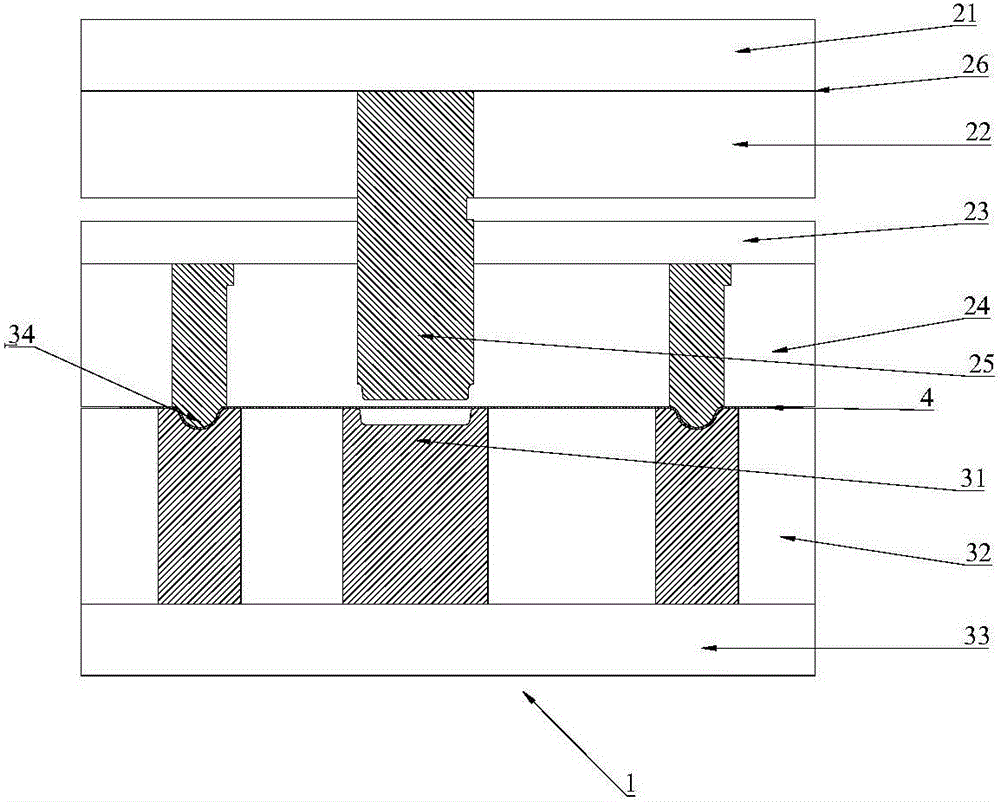

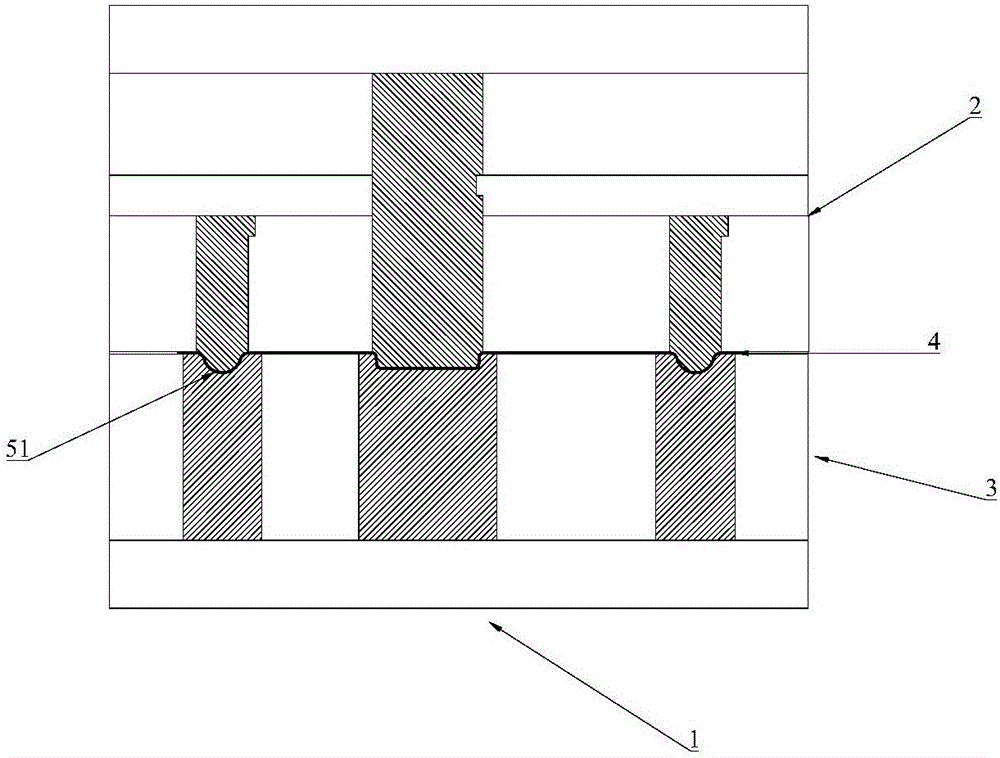

[0028] Please refer to figure 2 , a kind of drawing die 1 that can be used to form stretching part, comprises upper die part 2 and lower die part 3, and upper die part comprises punch fixing plate back plate 21, punch fixing plate 22, stripping back plate 23, The stripping plate 24, the punch 25 and the nitrogen spring 26 are composed, and the nitrogen spring is installed between the punch fixing plate back plate 21 and the punch fixing plate 22, and the stripping plate 24 and the stripping back plate 23 are provided with a The through hole, the punch 25 is located in the through hole; the stripper plate is provided with two oppositely arranged flange bumps for ribbing, and the two flange bumps are arranged on the preformed The two long sides of the stretched part, that is, the two long sides of the punch. The lower mold part includes a lower mold plate 32 and a lower mold back plate 33 , and the lower mold plate 32 is provided with a groove corresponding to the flange bump ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com