Modular integrated circuit and producing method thereof

An integrated circuit and modular technology, applied in the direction of circuit, semiconductor/solid-state device manufacturing, electrical components, etc., can solve problems such as poor flatness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

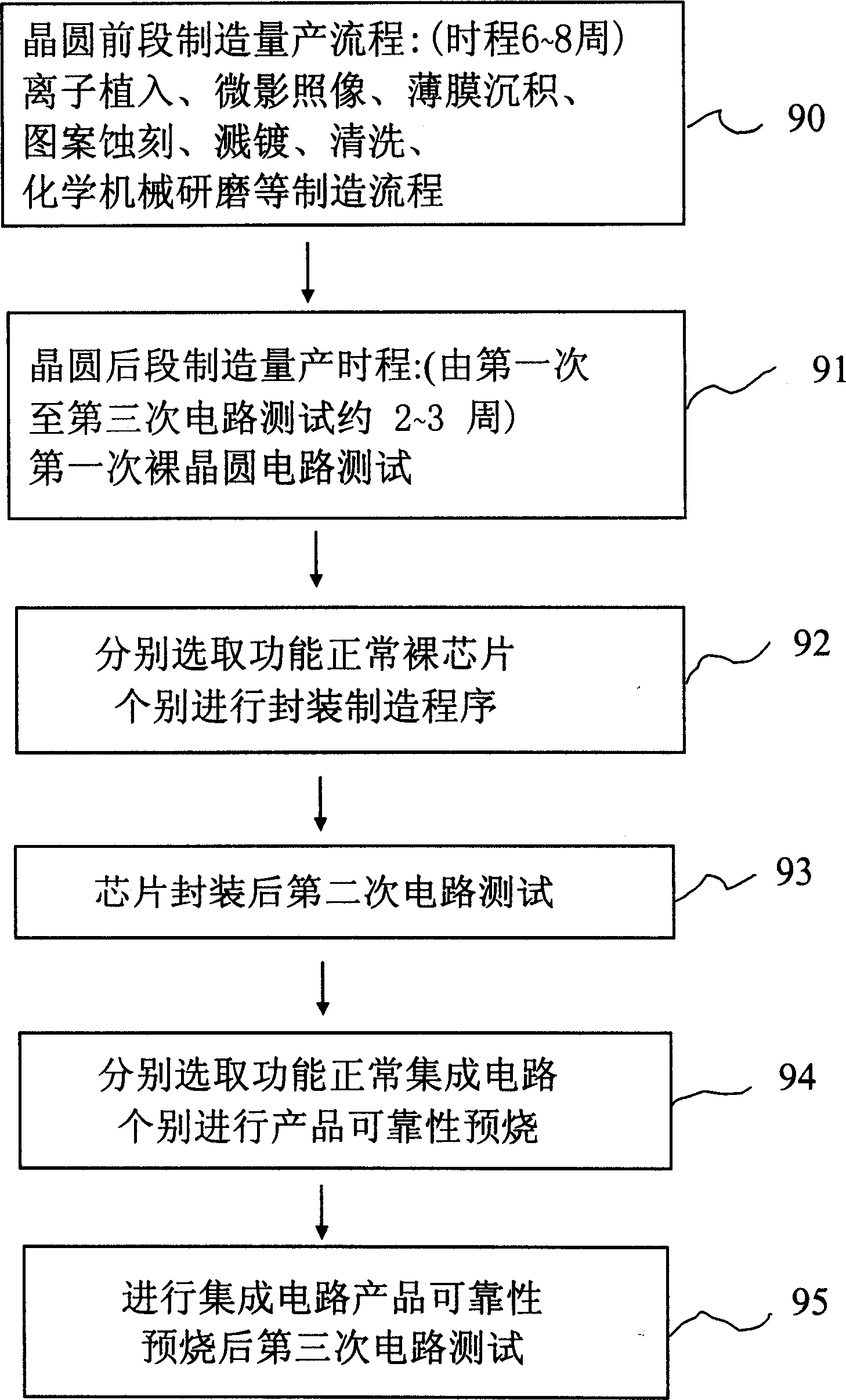

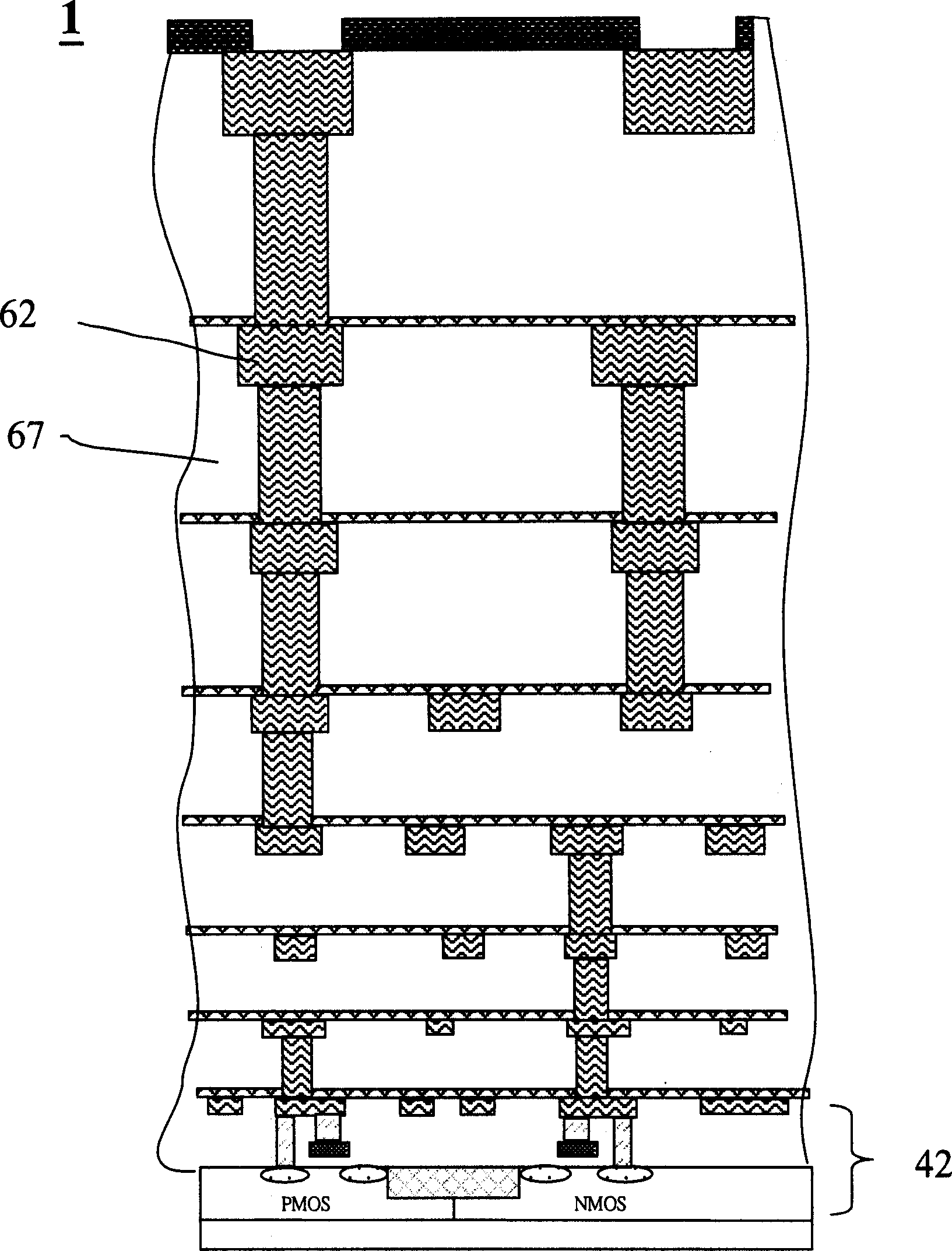

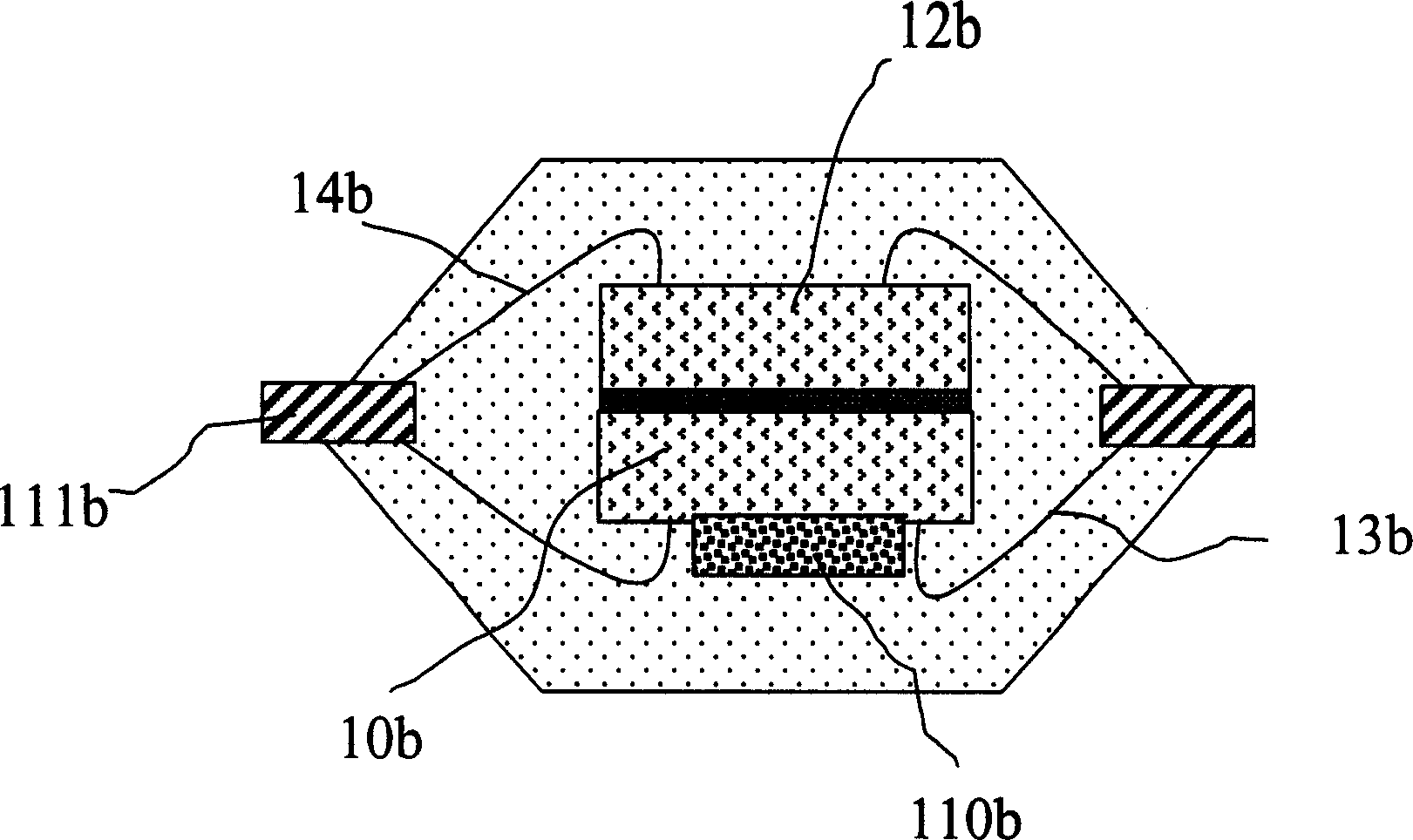

[0046] see Figure 5 , which is a schematic flowchart illustrating a method for manufacturing a modular integrated circuit of the present invention. As shown in the figure, the process flow of the modular integrated circuit manufacturing method of the present invention mainly includes the following steps: a wafer front-end functional module manufacturing process 90A, which can form a functional module 40 in a first wafer manufacturing site. The functional module 40 can form at least one functional component 42 on a functional substrate 41 (step 1A); the wafer front-end conductive layer module manufacturing process 90B can form a conductive layer module in a second wafer fabrication site, The conductive layer module 60 can be formed with at least one conductive layer 62 on a conductive layer substrate 61 (step 1B); The module 40 and the conductive layer module 60 are bonded, and at least one functional component 42 on the functional module 40 forms a conductive path with the co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com