Array substrate and manufacturing method thereof, display panel and display device

A technology for array substrates and display panels, applied in semiconductor/solid-state device manufacturing, diodes, semiconductor devices, etc., can solve the problems of low reliability of OLED display panels, improve color separation, improve surface flatness, and improve product reliability degree of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0052] In order to make the objectives, technical solutions and advantages of the present invention clearer, the embodiments of the present invention will be further described in detail below with reference to the accompanying drawings.

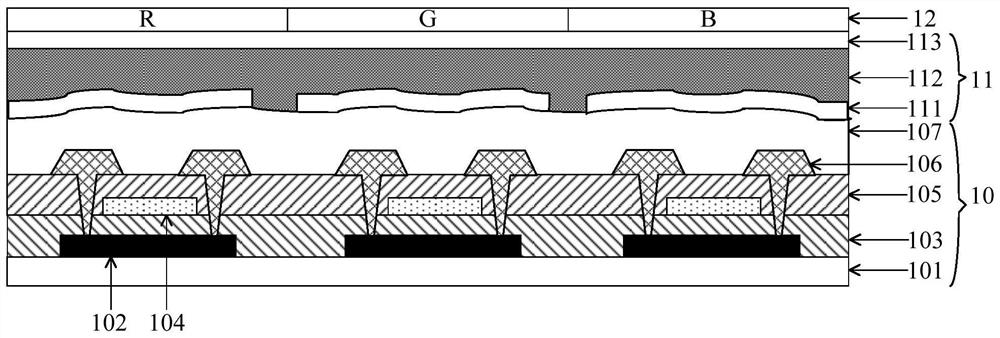

[0053] figure 1It is a schematic structural diagram of an OLED display panel provided in the related art, such as figure 1 As shown, the OLED display panel includes an array substrate 10 , a light-emitting device 11 located on the array substrate 10 , and a filter 12 located on the light-emitting side of the light-emitting device 11 . see figure 1 , the array substrate 10 includes a base substrate 101, and an active layer 102, a passivation layer 103, a gate pattern 104, an interlayer insulating layer 105, a source-drain pattern 106 and a flat layer 107 stacked on the base substrate 101 ; The light-emitting device 11 includes a first electrode 111, a light-emitting layer 112 and a second electrode 113; the filter 12 has a red filter area R,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com