An automatic line clamping adapter block

An automation line and transfer block technology, which is applied in the direction of manufacturing tools and manipulators, can solve problems such as the existence of edges and corners in the transfer block of the end picker, excessive load on the robot, and complex structure of the clamping transfer block, so as to improve work stability. High performance, improved production efficiency, safe and not easy to scratch

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

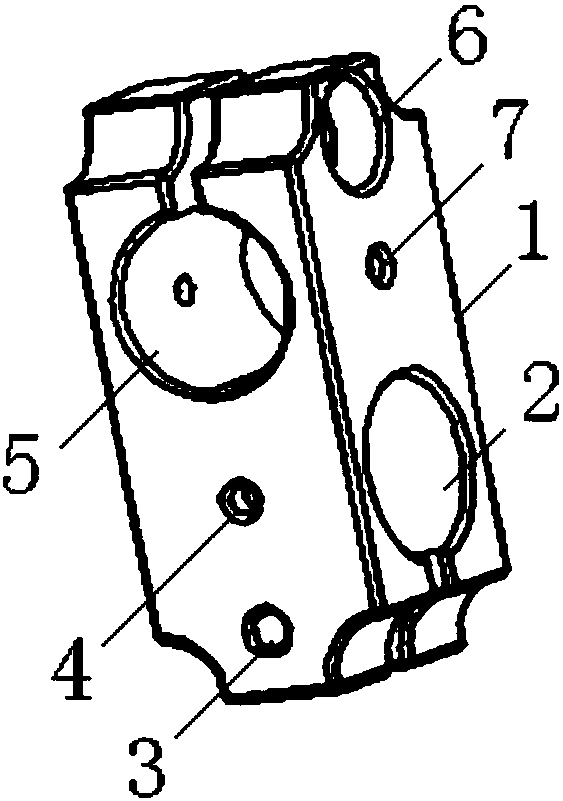

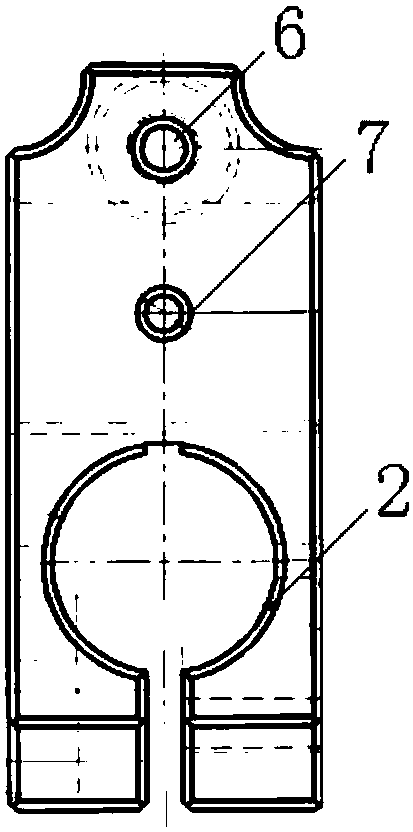

[0019] The specific implementation manner of the present invention will be described in further detail below by describing the embodiments with reference to the accompanying drawings.

[0020] like figure 1 and figure 2 As shown, the automation line clamps the transfer block, including the transfer block body 1, the transfer block body 1 is like a cuboid structure as a whole, the four corners of the transfer block body 1 are provided with arc grooves, and the transfer block body Each edge is a chamfered structure. Light weight, reduce the load of the robot, improve work stability; safe and not easy to scratch the product, reliable work.

[0021] The adapter block body 1 has an integral structure, simple structure and light weight. One end of the adapter block body is provided with a first clamping hole 2, and the other end of the adapter block body is provided with a second clamping hole 5. The first clamping hole and the second clamping hole are both open holes. Fastenin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com