Vertical arranging method of laminated glass in autoclave

A laminated glass and autoclave technology, applied in chemical instruments and methods, lamination, lamination auxiliary operations, etc., can solve the problems of glue cannot be eliminated, unsightly, poor overall appearance of laminated glass products, etc., to achieve the elimination of bowls Shaped optical deformation, beautiful appearance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be described in further detail below in conjunction with the embodiments and accompanying drawings.

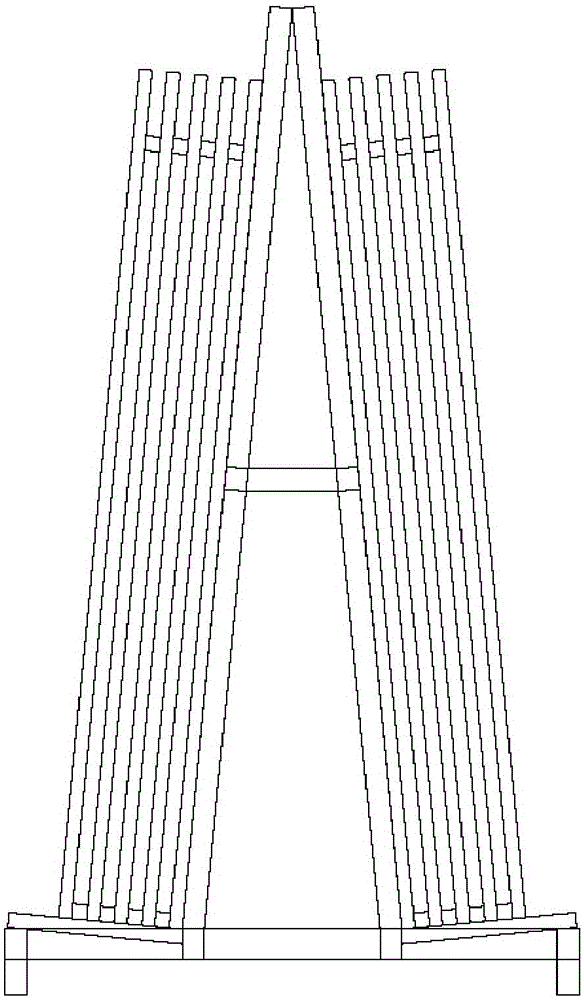

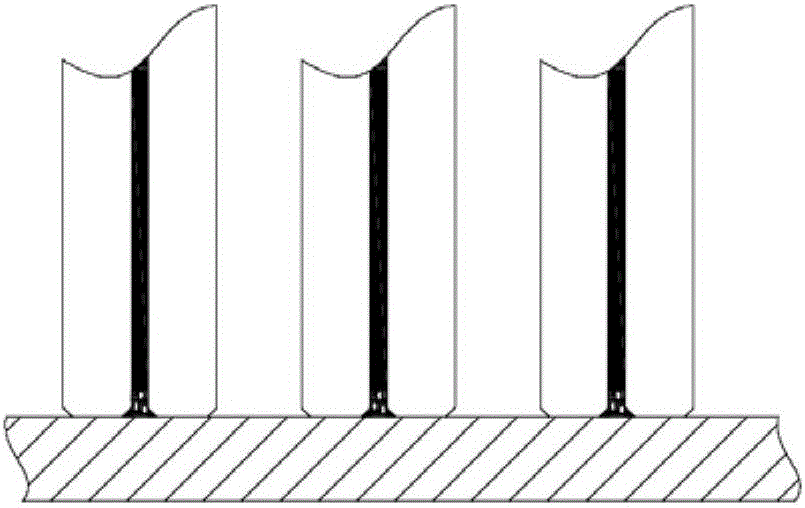

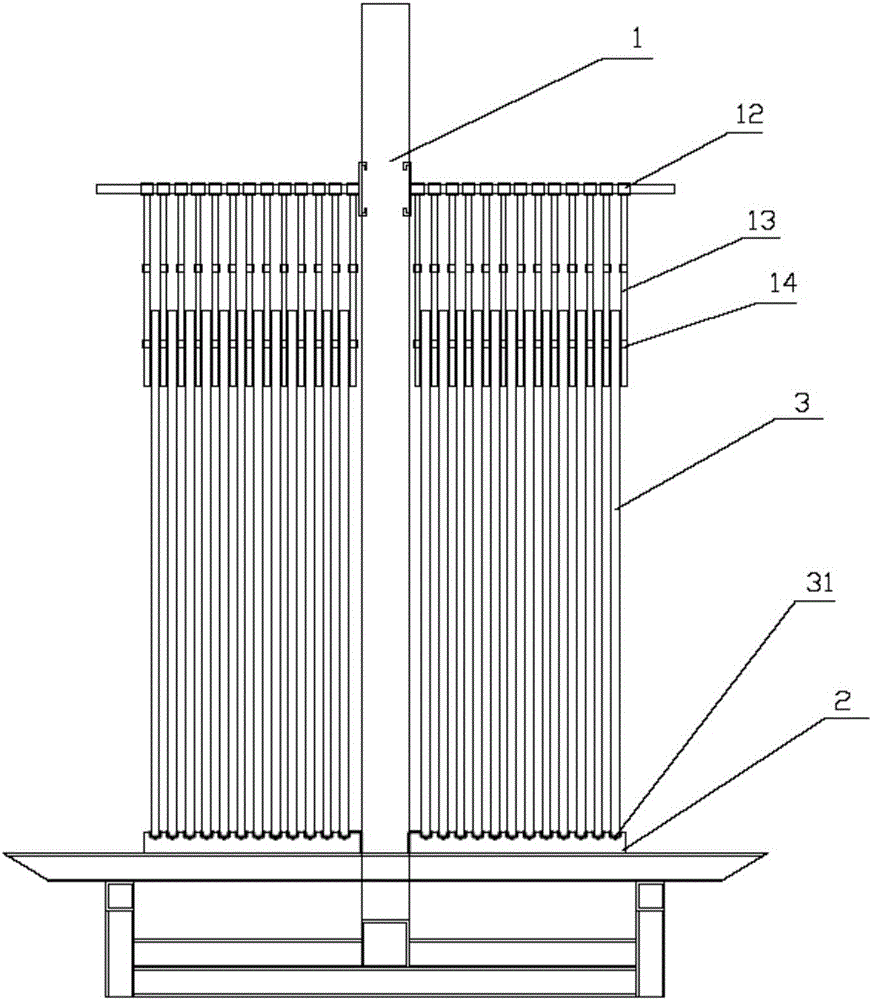

[0023] Such as image 3 , 4 , 5, a vertical stacking method for laminated glass in an autoclave, is characterized in that: the laminated glass 3 is vertically fixed and stacked on the car that enters the kettle, and the bottom of the laminated glass 3 corresponds to the position of the internal film A holding tank 22 is provided to accommodate the extruded film 31 and exhaust air during high temperature and high pressure. In the present invention, the original A-shaped oblique vertical code method is changed into a vertical parallel fixed code method, so that there is no mutual extrusion between the laminated glass 3, and bowl-shaped deformation is avoided. At the bottom, a holding tank 22 is opened. During the process of high temperature and high pressure, the extruded film 31 can be accommodated in the holding tank 22, giving it a space to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com