Small and medium aluminium product anodic oxidation device and anodic oxidation method

A technology of anodizing and aluminum products, applied in the direction of anodizing, electrolytic coating, surface reaction electrolytic coating, etc., can solve the problems of complex overall structure and high equipment input cost, and achieve the effect of simple connection and reduced input cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

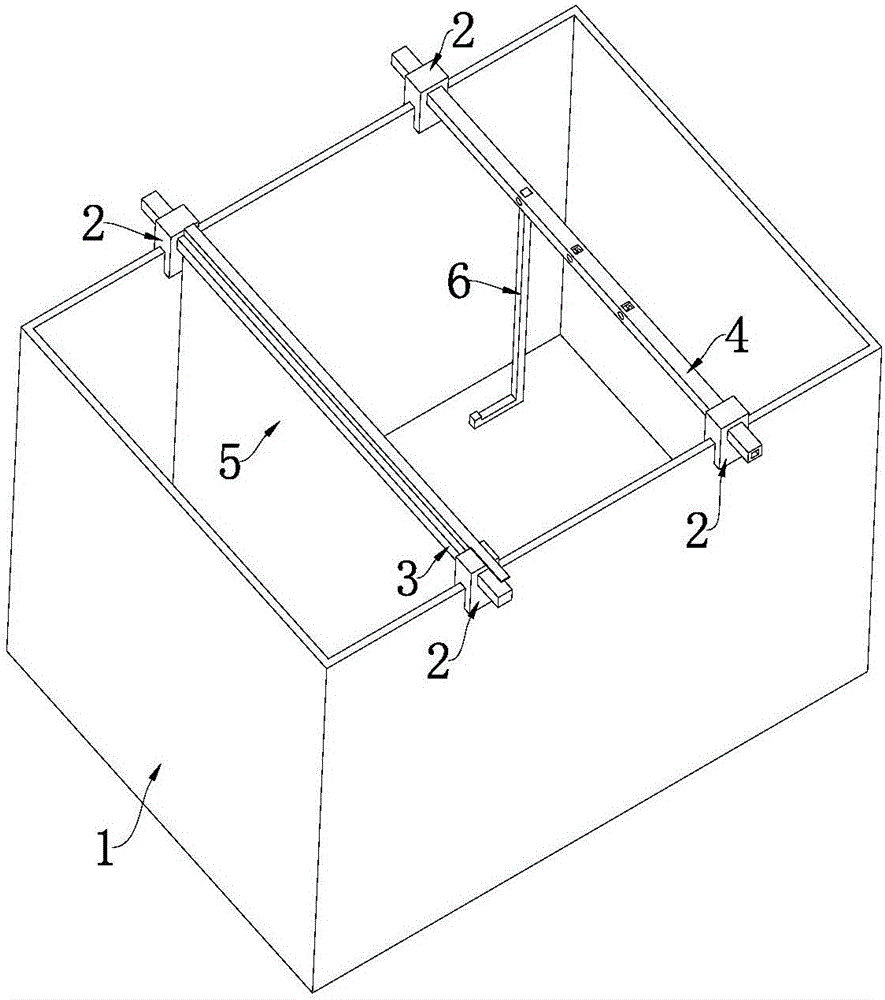

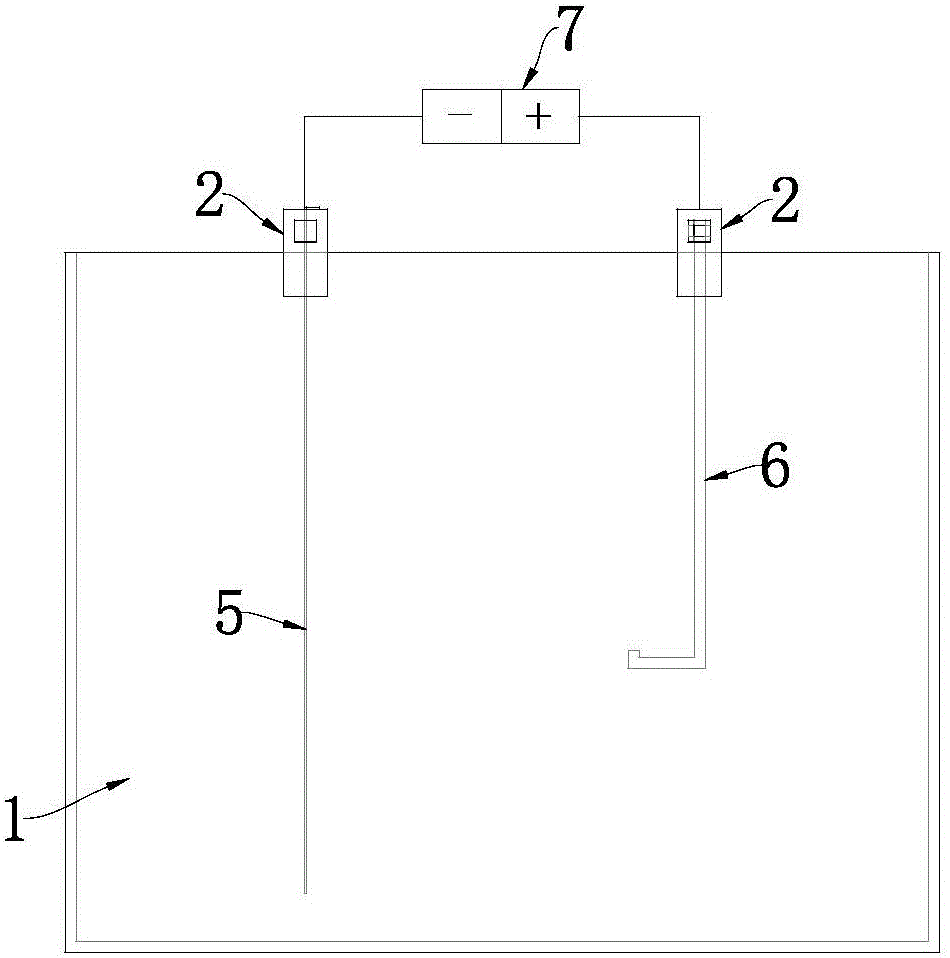

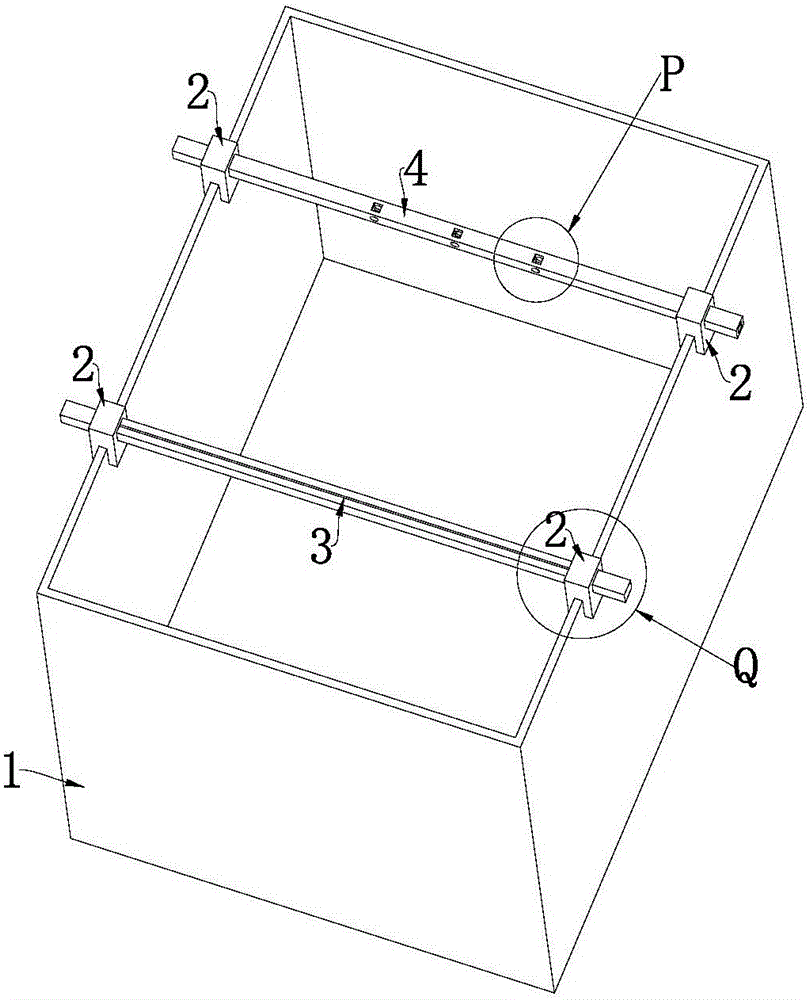

[0033] Such as Figure 1-3 As shown, the anodizing device for small and medium-sized aluminum products of the present invention includes: a power supply 7 , a solution tank 1 , a fixing frame 2 , a cathode rod 3 , an anode rod 4 , a cathode plate 5 and a workpiece holder 6 . Two sets of fixing frames 2 are installed on the upper edge of the solution tank 1; specifically: as Figure 4 As shown, each fixed frame 2 bottom has a draw-in groove 21, and the side has a chute 22; as Figure 5 As shown, each fixing bracket 2 is clamped to the upper edge of the solution tank 1 through the clamping groove 21 at the bottom end thereof. The cathode rod 3 and the anode rod 4 are respectively plugged into the chute 22 corresponding to the fixing frame 2 . The cathode plate 5 and the workpiece holder 6 (clamps or hooks) are respectively arranged in the solution tank 1, and the cathode plate 5 and the workpiece holder 6 are detachably installed on the cathode rod 3 and the anode rod 4 respec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com