A method for erecting a split steel bridge

A steel bridge, split-type technology, applied in the field of erection of split-type steel bridges, can solve the problems of insufficient erection efficiency, large counterweight, high energy consumption, etc., and achieve the effects of high erection efficiency, lightening requirements, and low energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

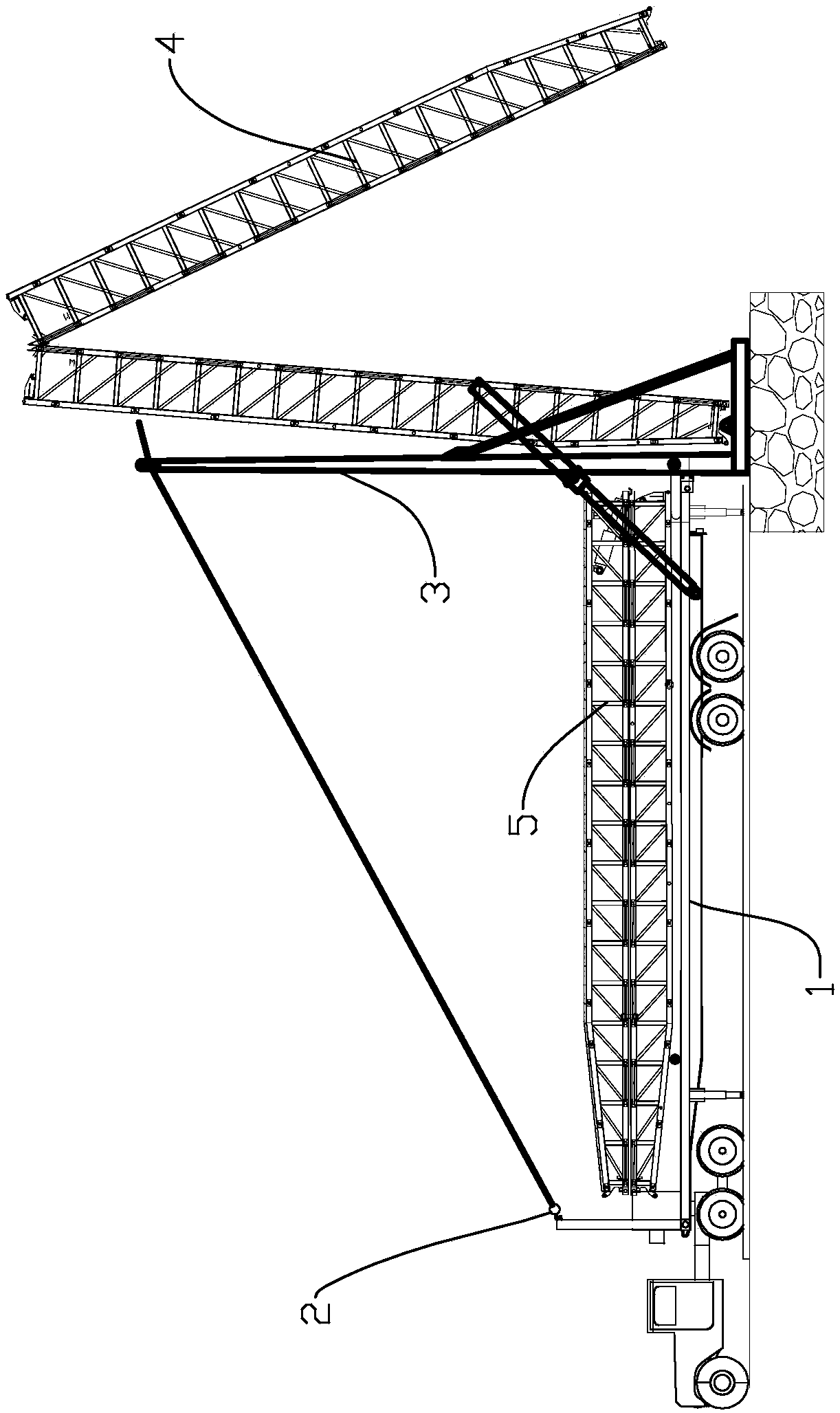

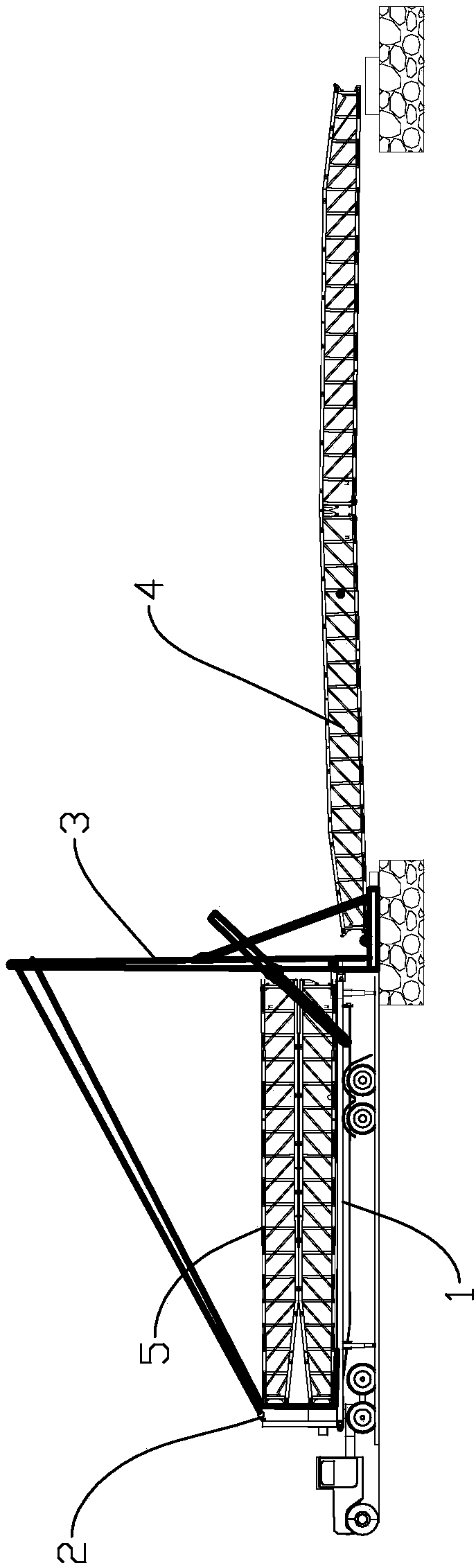

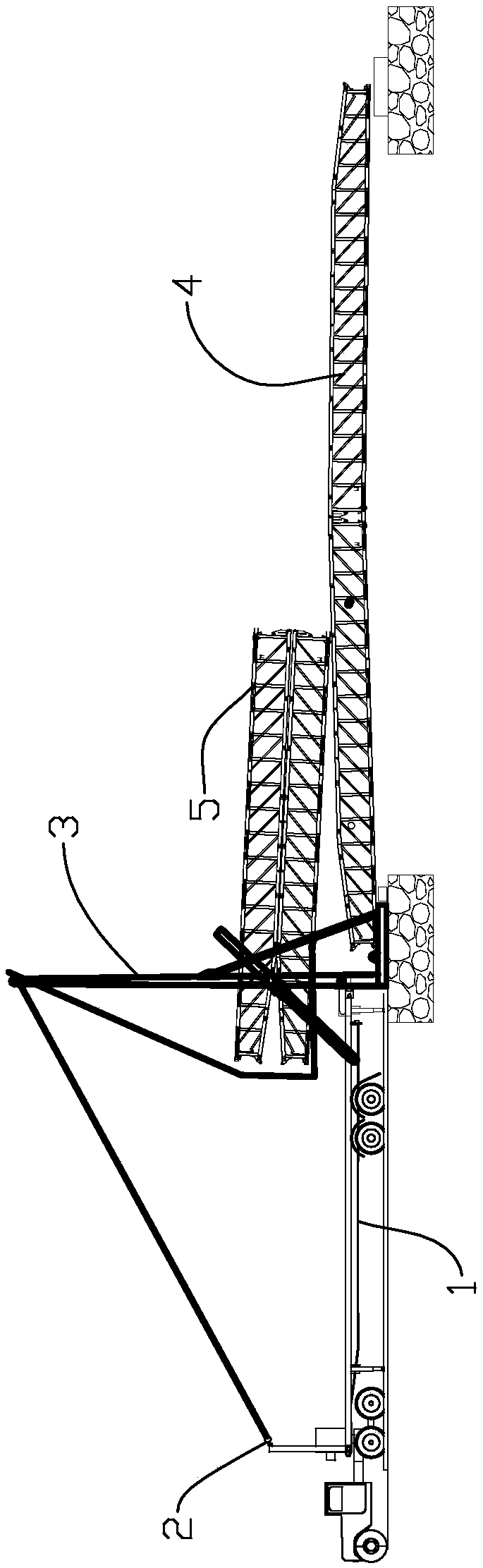

[0023] refer to Figure 1 to Figure 5 , the present invention is a method for erecting a split-type steel bridge. The split-type steel bridge includes a base 1, a foldable first bridge body 4 and at least one foldable second bridge body 5, comprising the following steps:

[0024] 1. Put the folded first bridge body 4 upright, the rotation center of the first bridge body 4 is at the top, the two ends of the first bridge body 4 are at the bottom, and one end of the first bridge body 4 and the base 1 can rotate ground connection;

[0025] 2. The first bridge body 4 has its own retracting mechanism, which drives the first bridge body 4 to expand, and controls the first bridge body 4 to gradually descend until the other end of the first bridge body 4 is installed;

[0026] 3. Push the second bridge body 5 onto the erected first bridge body 4. After the second bridge body 5 is in place, connect one end of the second bridge body 5 with the first bridge body 4, and the second bridge ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com