Multi-tube combined steel column and manufacturing method thereof

A technology of steel columns and steel pipes, which is applied in the field of combined steel columns, multi-tube combined steel columns and their production, can solve problems such as poor bearing capacity, inability to fit, poor structural performance, etc., and achieve good mechanical performance and clear force transmission , On-site operational effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

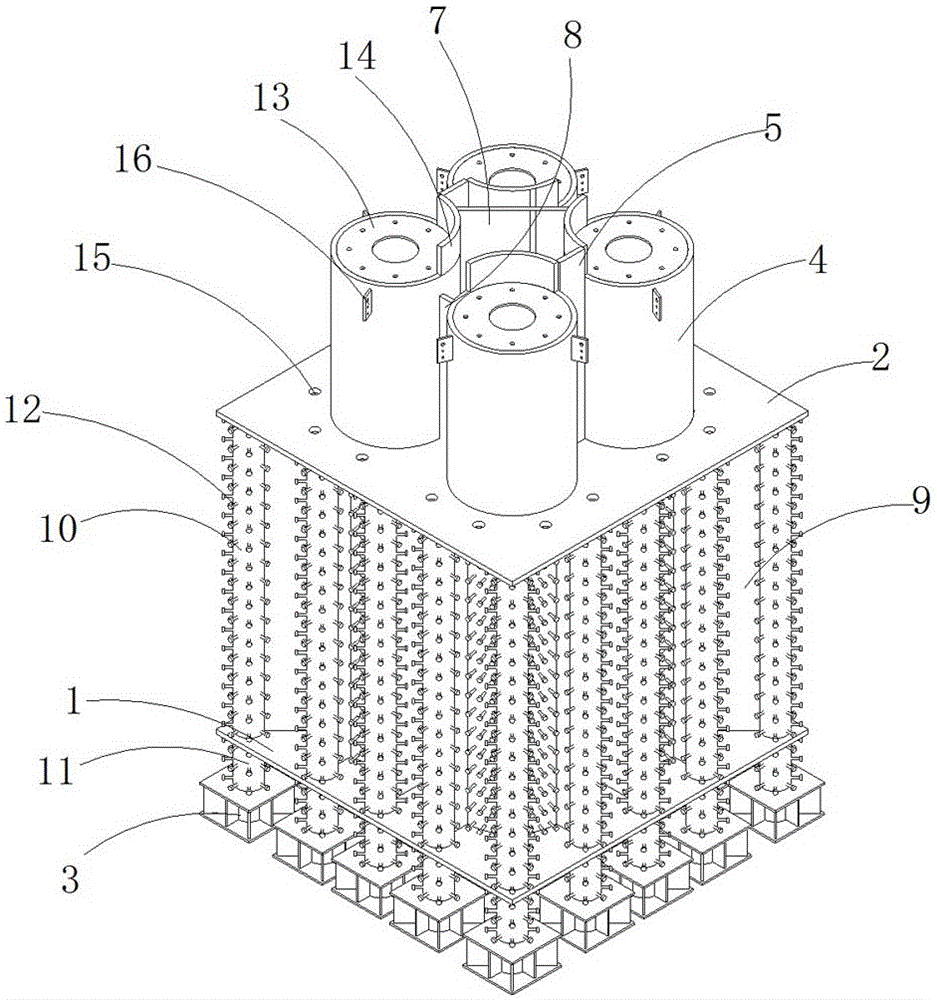

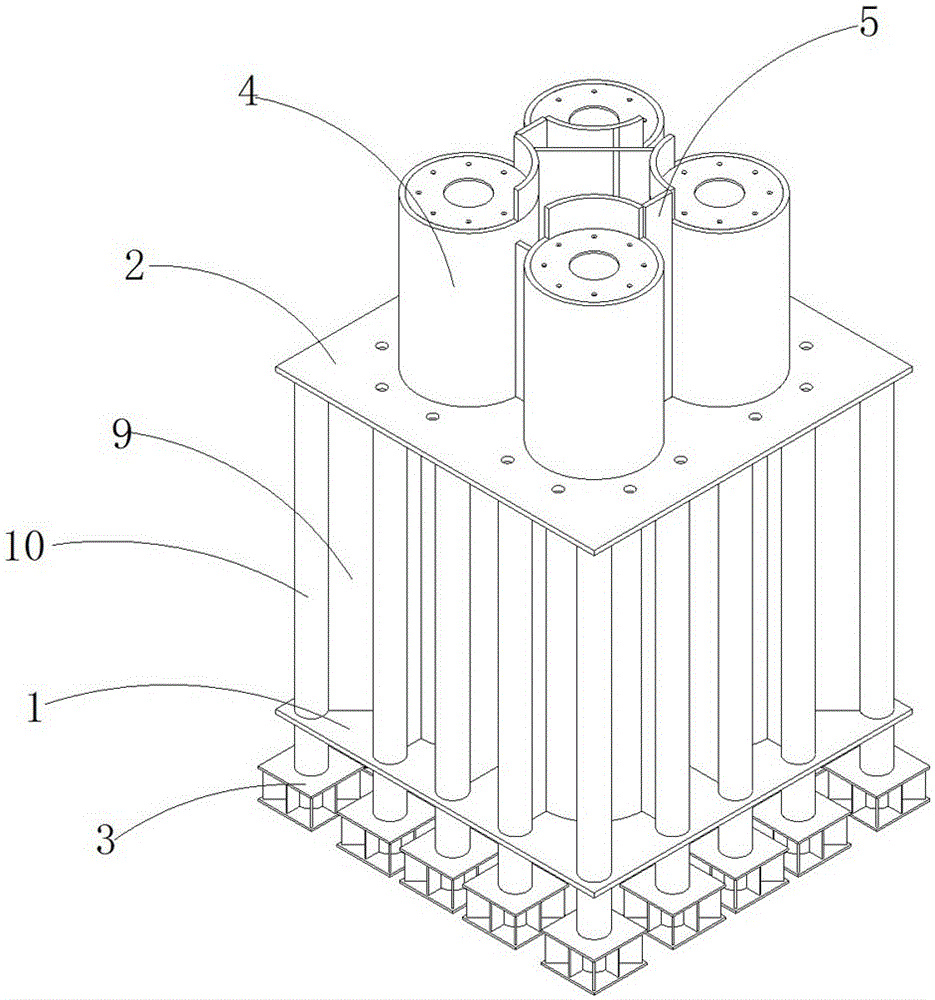

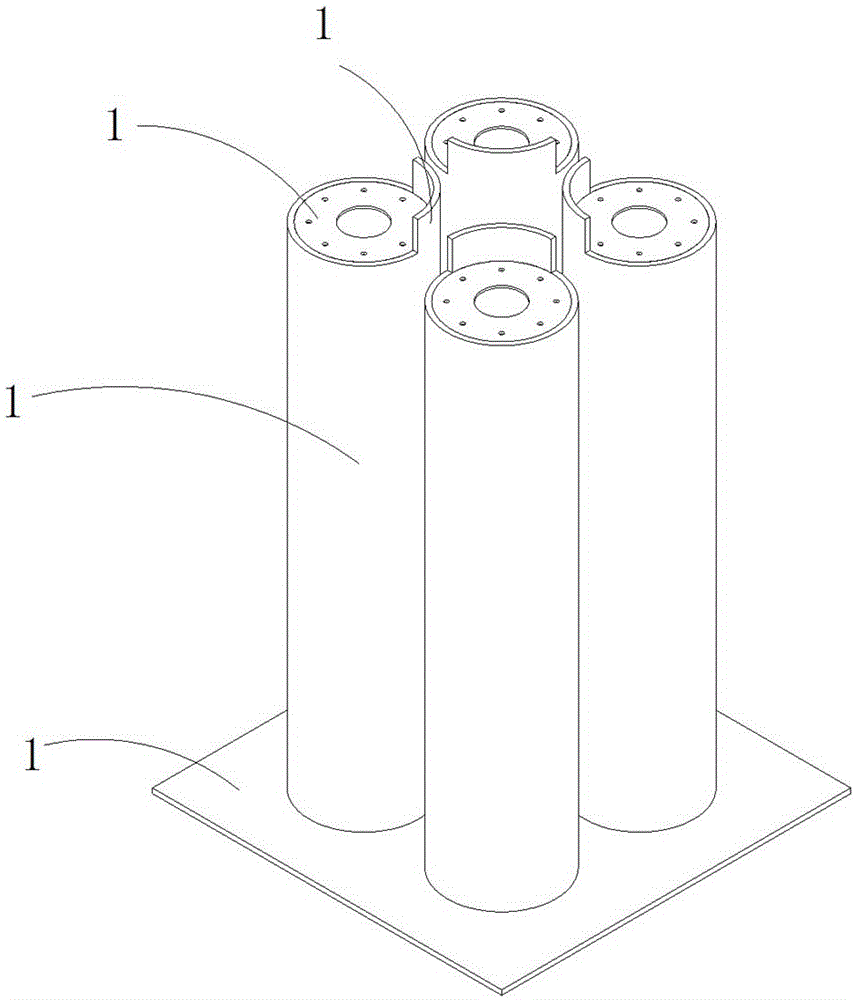

[0065] Embodiment 1: as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Figure 6 , Figure 7 , Figure 8 , Figure 9 , Figure 10 and Figure 11 As shown, a multi-tube composite steel column includes a column bottom plate 1, a main steel pipe assembly is arranged on the upper part of the column bottom plate 1, and an outer ring partition 2 is placed on the outer ring of the main steel pipe assembly, and the column bottom plate 1 The upper part of the column is provided with a small steel pipe assembly fixed with the main steel pipe assembly, and the bottom of the column floor 1 is provided with several shear keys 3;

[0066] The main steel pipe assembly includes 4 main steel pipes 4 distributed in a square shape at intervals, wherein a pair of symmetrically distributed main steel pipes 4 are positioned by strip-shaped long connecting plates 5, and the outer ring partition 2 is connected to the main steel pipes. The steel pipes are socketed in 4 phases, and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com