Lock tongue prefabricated container house connection point

A container and prefabricated technology, applied in the direction of construction and building structure, can solve the problems of slow and complicated installation, many manual operations, inconvenient recycling, etc., and achieves the effect of easy positioning requirements and improved construction speed.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

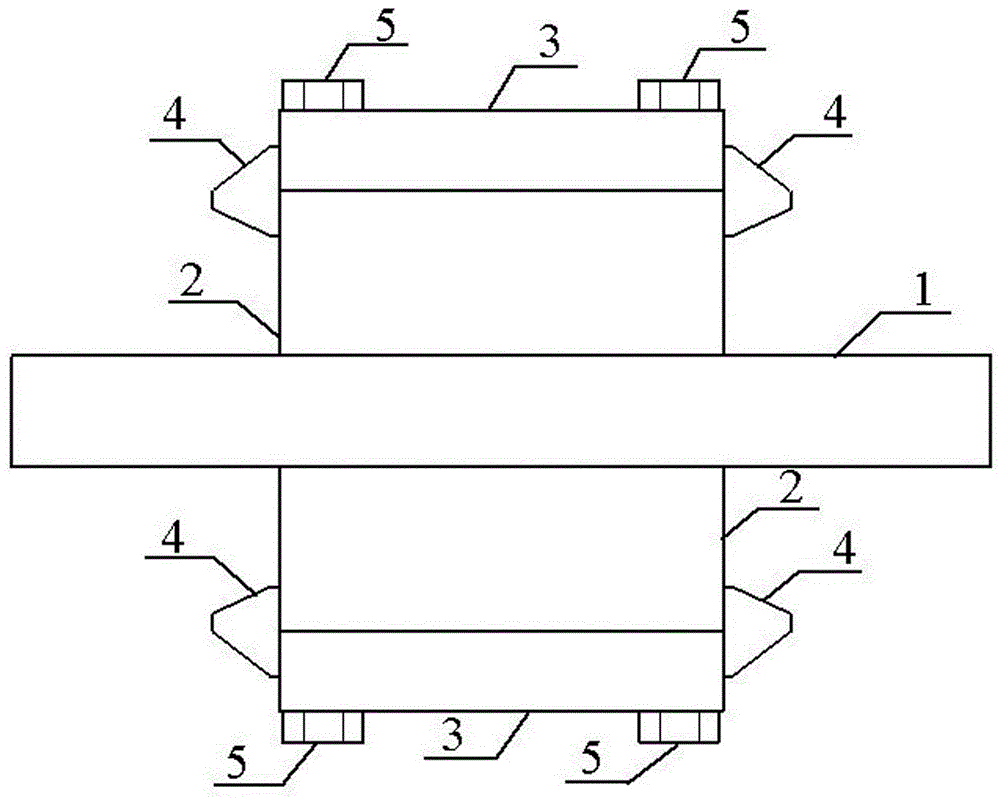

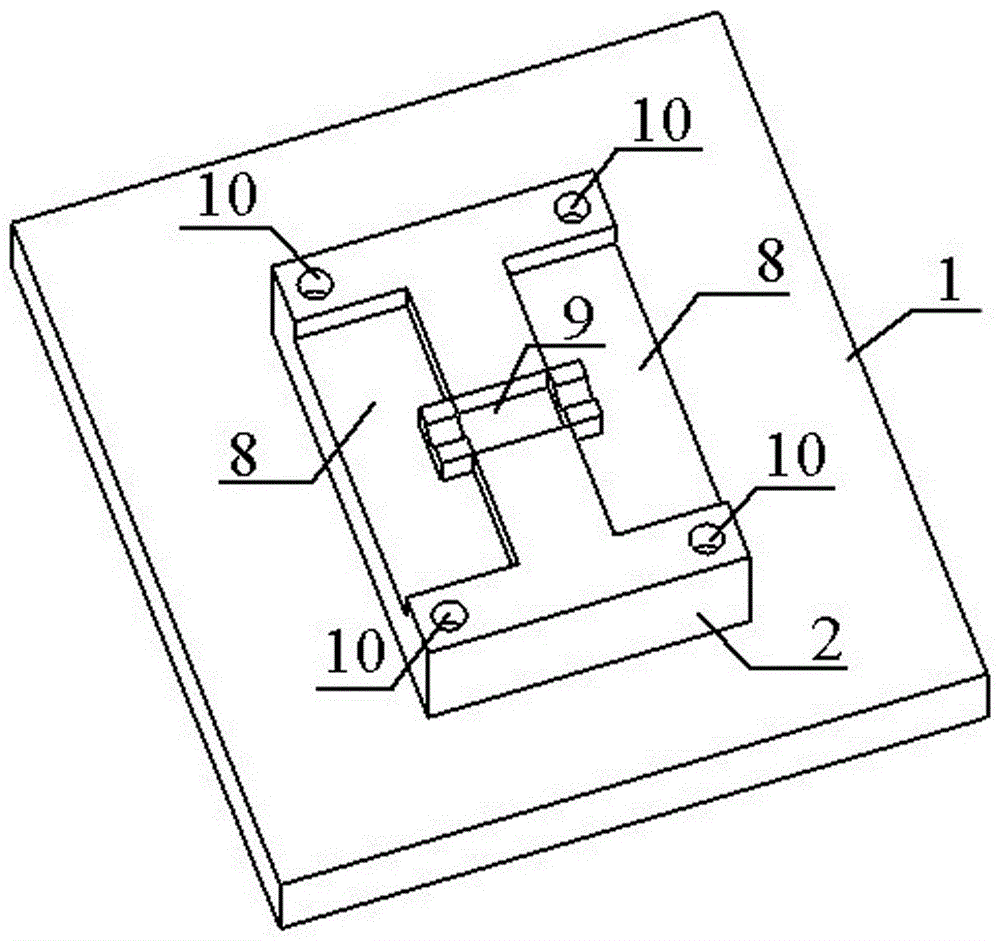

specific Embodiment 1

[0053] Specific embodiment one, such as Image 6 , as shown in 7 and 8, this connection node connects four containers up, down, left, and right. During specific installation, the gusset plate is first buckled into the top of the two container pillars positioned at the lower part under the action of external force, and then the upper two containers are hoisted separately. When the upper container column end sealing plate 12 starts to be buckled on the shear key 2, the dead bolt 4 can extend into the inside of the sliding channel 8 under the action of the container’s own weight due to the upper inclined surface with a relatively large degree of inclination, and the column end sealing plate After fully falling onto the gusset plate 1, the locking tongue 4 pops out of the groove under the action of the spring thrust and buckles the column end sealing plate, such as Image 6 with Figure 7 shown. Because the locking tongue 4 has a lower inclined surface with a small inclination,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com