A wind power generator magnetic coupling bearing system

A wind power generator and magnetic coupling technology, applied in wind power generators, wind power generation, magnetic bearings, etc., can solve the problems of increasing manufacturing costs without significantly improving bearing performance, achieving long service life, low manufacturing costs, and stability Good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] Describe the present invention in detail below in conjunction with embodiment and accompanying drawing. The embodiment is based on the specific implementation carried out on the premise of the technical solution of the present invention, and provides detailed implementation methods and processes. However, the protection scope of the claims of the present application is not limited to the description of the following embodiments.

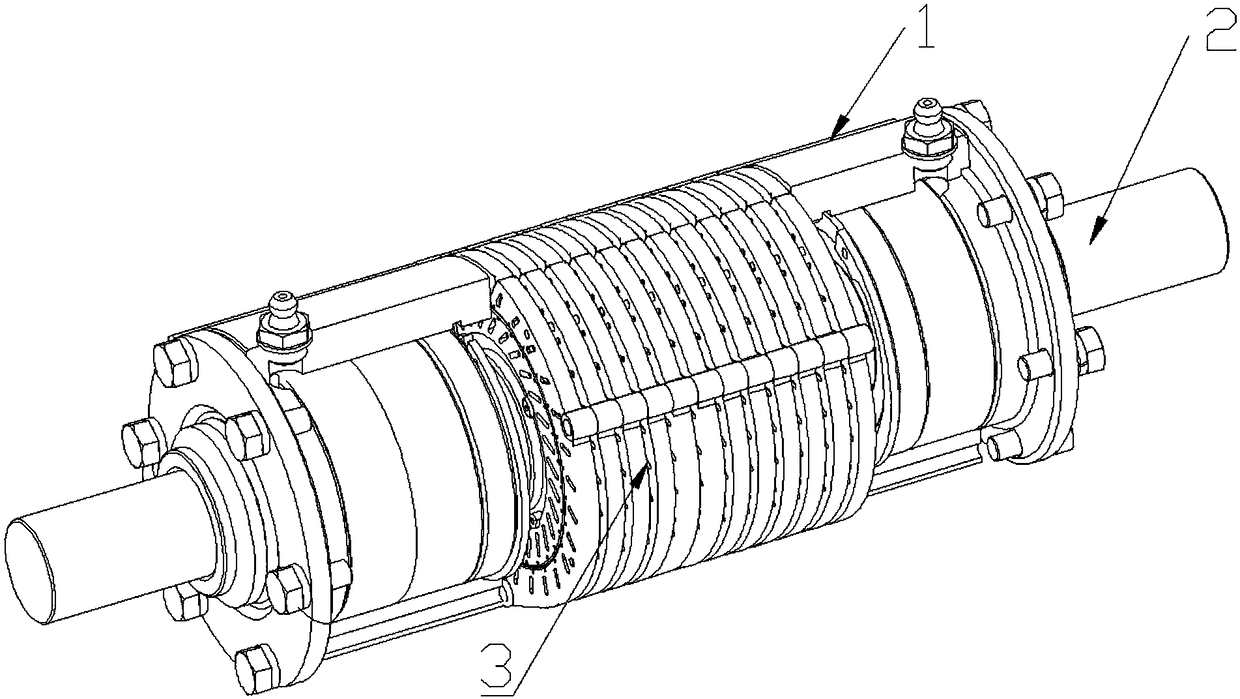

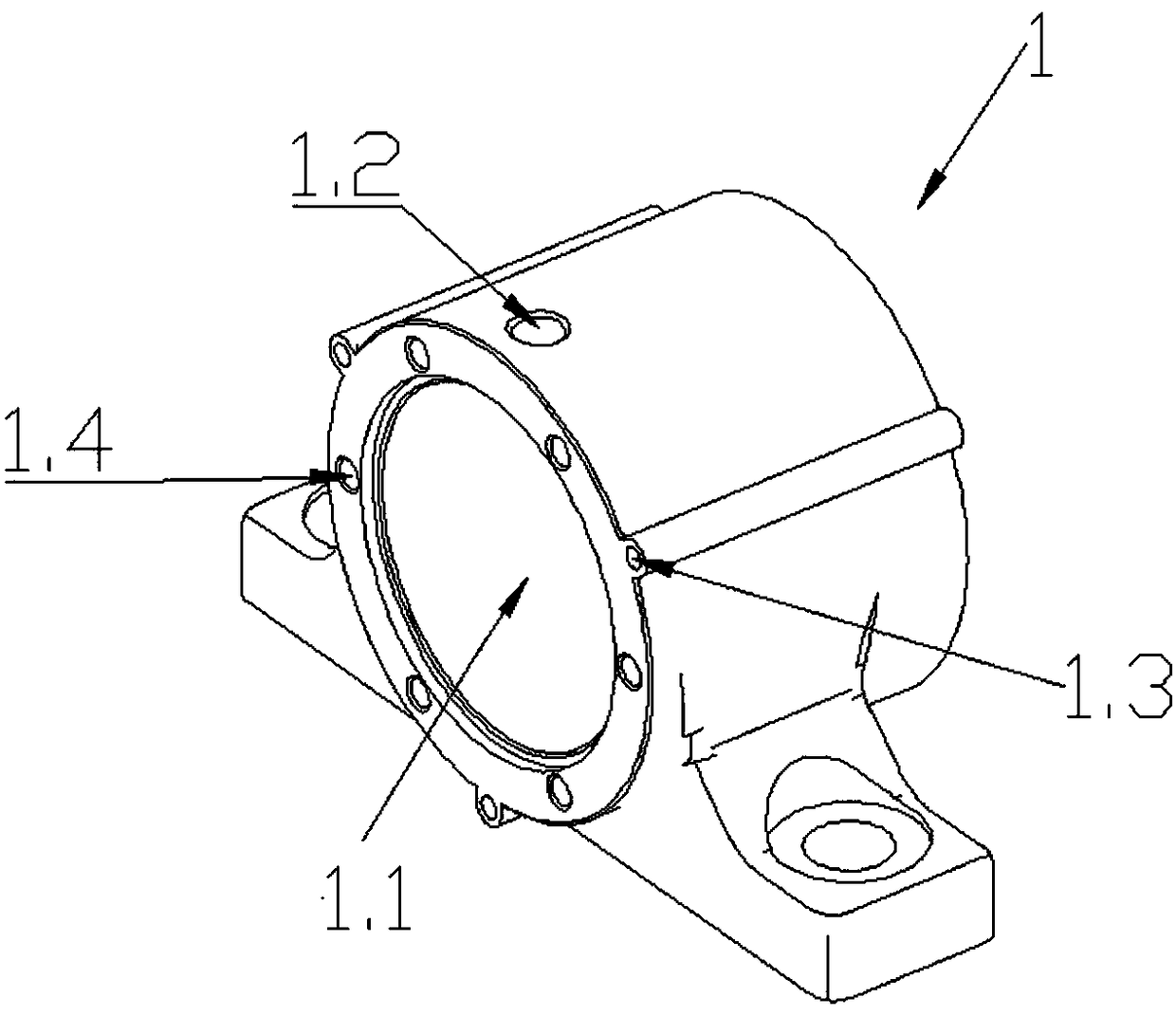

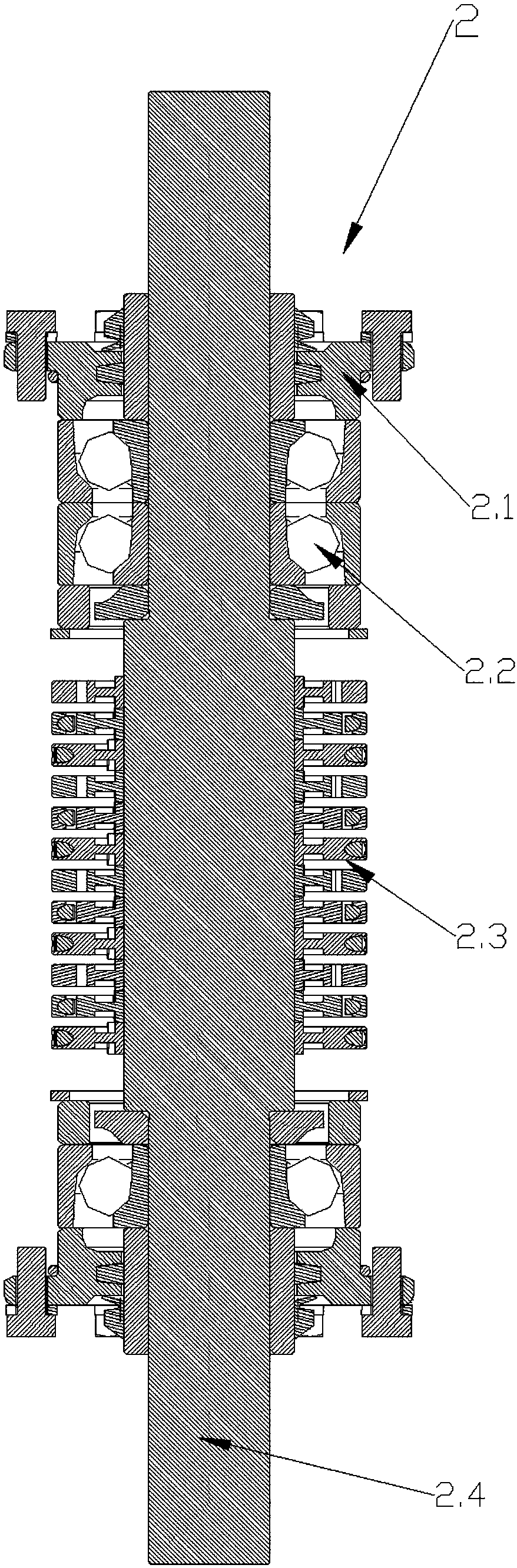

[0014] A kind of wind power generator magnetic coupling bearing system designed by the present invention (referred to as bearing system, see Figure 1-6 ), the bearing system mainly includes housing 1, shaft system 2 and outer magnetic ring 3; housing 1 (see figure 2 ) is provided with a casing rotating shaft through hole 1.1, a casing lubricating hole 1.2, a casing outer magnetic ring mounting hole 1.3 and a casing bearing cover flange 1.4, and the casing rotating shaft passing hole 1.1 cooperates with the bearing 2.2 on the rotating shaft ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com