A winch control device

A winch, hydraulic control reversing valve technology, applied in the direction of hoisting device, fluid pressure actuating device, servo motor, etc., can solve the problems of loss, low accuracy, time-consuming and labor-intensive, etc. cost reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

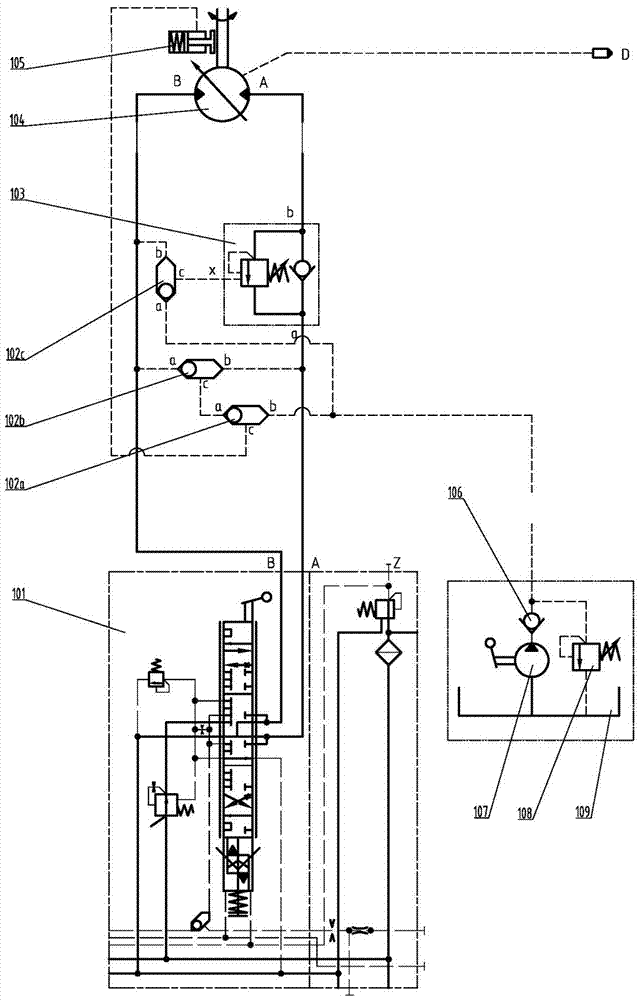

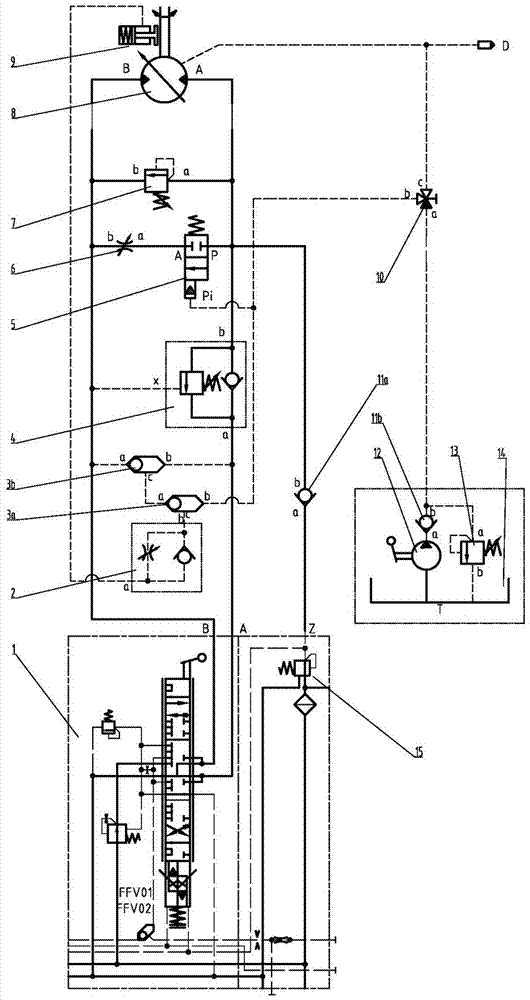

[0057] Such as figure 2A drawworks control device shown includes a load sensitive multi-way valve 1, a one-way throttle valve 2, a first shuttle valve 3a, a second shuttle valve 3b, a balance valve 4, a two-position two-way hydraulic control reversing valve 5, Throttle valve 6, safety valve 7, winch motor 8, winch brake 9, three-way ball valve 10, first one-way valve 11a, second one-way valve 11b, hand pump 12, overflow valve 13, oil tank 14, decompression Relief valve 15, port A of load sensing multi-way valve 1 is connected to port b of second shuttle valve 3b, port b of second shuttle valve 3b is connected to port a of balance valve 4, port b of balance valve 4 is connected to port The P port of the two-position two-way hydraulic control reversing valve 5 is connected, the P port of the two-position two-way hydraulic control reversing valve 5 is connected to the a port of the safety valve 7, and the a port of the safety valve 7 is connected to the A port of the winch motor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com