Experimental measurement method for uniaxial tension of hydrogel materials based on back-shaped specimens

A hydrogel, test piece technology, applied in the direction of measuring devices, analyzing materials, testing the strength of materials by applying stable tension/pressure, etc., to achieve the effect of good mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below in conjunction with specific examples.

[0020] The hydrogel material uniaxial tensile test measurement method based on the back type test piece described in the present embodiment, its situation is as follows:

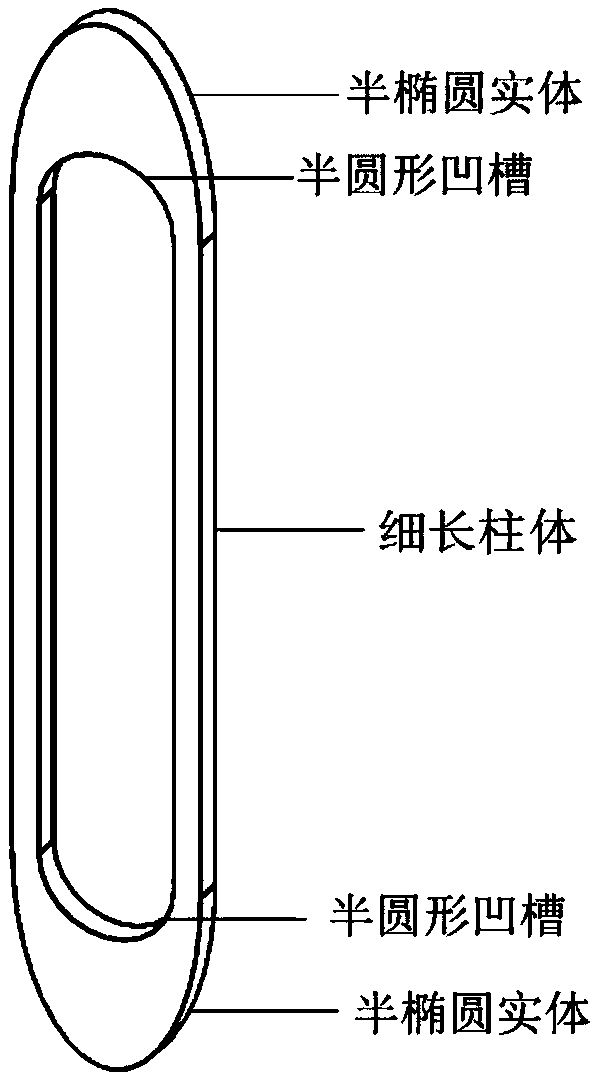

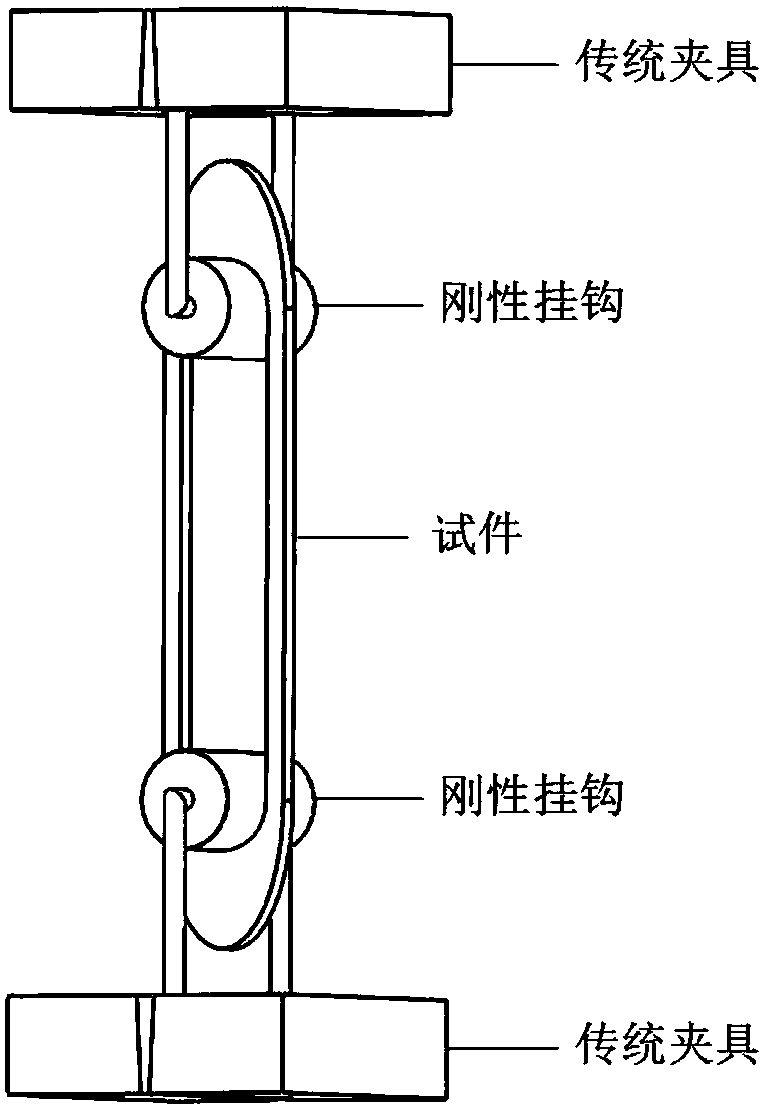

[0021] An example test piece is a PVA (polyvinyl alcohol) hydrogel (moisture content is about 80%) material. The appearance of the test piece looks like an elongated "Hui" character, which looks like a rubber band and is symmetrical from left to right, such as figure 1 As shown, the details are as follows: two parallel slender cylinders are 50mm long, the side length of the section is 2mm, and the distance between them is 10mm; the upper and lower ends of the cylinders are respectively connected by semi-elliptical entities, and the semi-elliptical major axis is 15mm, and the minor semi-axis is 7mm , with a thickness of 2 mm; a semi-elliptical solid near the end faces of two parallel cylinders forms a semi-c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| elastic modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com