CO2 triaxial seepage test system and method in rock chemical corrosion environment

A corrosive environment and petrochemical technology, applied in measurement devices, scientific instruments, permeability/surface area analysis, etc., can solve problems such as not much research

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described below in conjunction with the accompanying drawings.

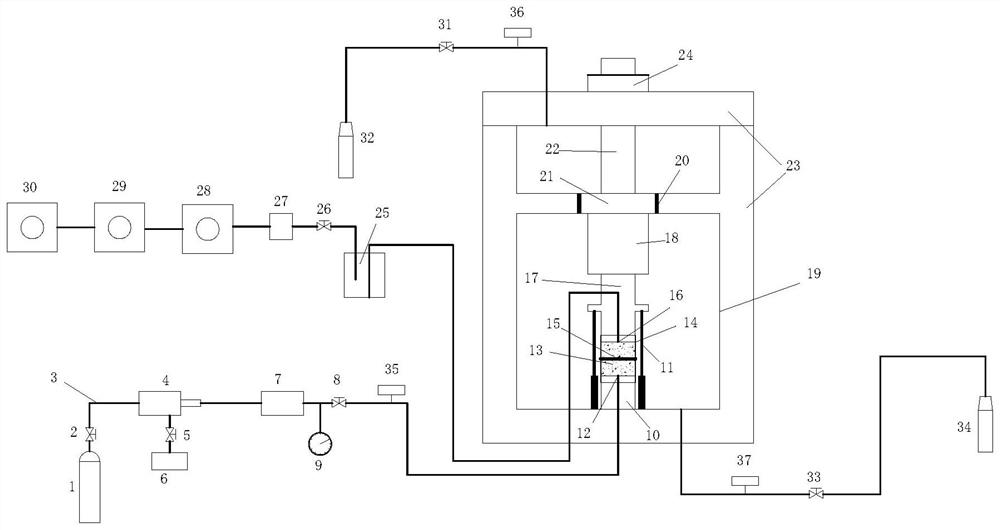

[0027] Such as figure 1 As shown, CO in a rock chemical corrosion environment of the present invention 2 A triaxial seepage test system, including a pressure chamber 19, a gas pressurization system, a bias pressure pump 32, a confining pressure pump 34, an exhaust system and a pressure test device, wherein:

[0028] A platform 10 is arranged at the inner bottom of the pressure chamber 19, on which a rock sample 13 is placed, and an axial dowel rod 18 is arranged at the top of the pressure chamber 19, and the lower end of the axial dowel rod 18 is connected with an indenter 17, and the indenter 17 The lower end is in contact with the top of the rock sample 13; the upper ring of the rock sample 13 is provided with an annular strain gauge 15, and the two sides of the rock sample 13 are provided with axial strain gauges 11. The upper end of the axial strain gauge 11 is fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com